Disk brake cylinder assembly with parking mechanism and brake caliper

A disc brake and parking mechanism technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the wear and tear of parts and the reduction of mechanism efficiency, increase the difficulty of parts manufacturing and coordination, processing accuracy and assembly requirements Advanced problems, to achieve the effect of reducing manufacturing costs, reducing the number of parts, and improving matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

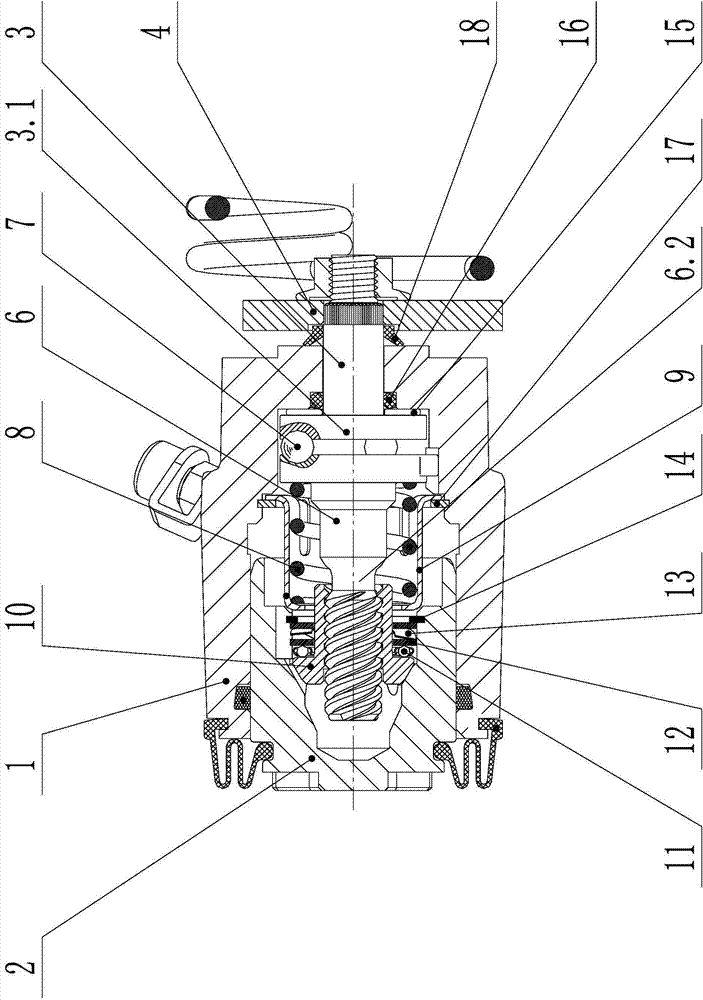

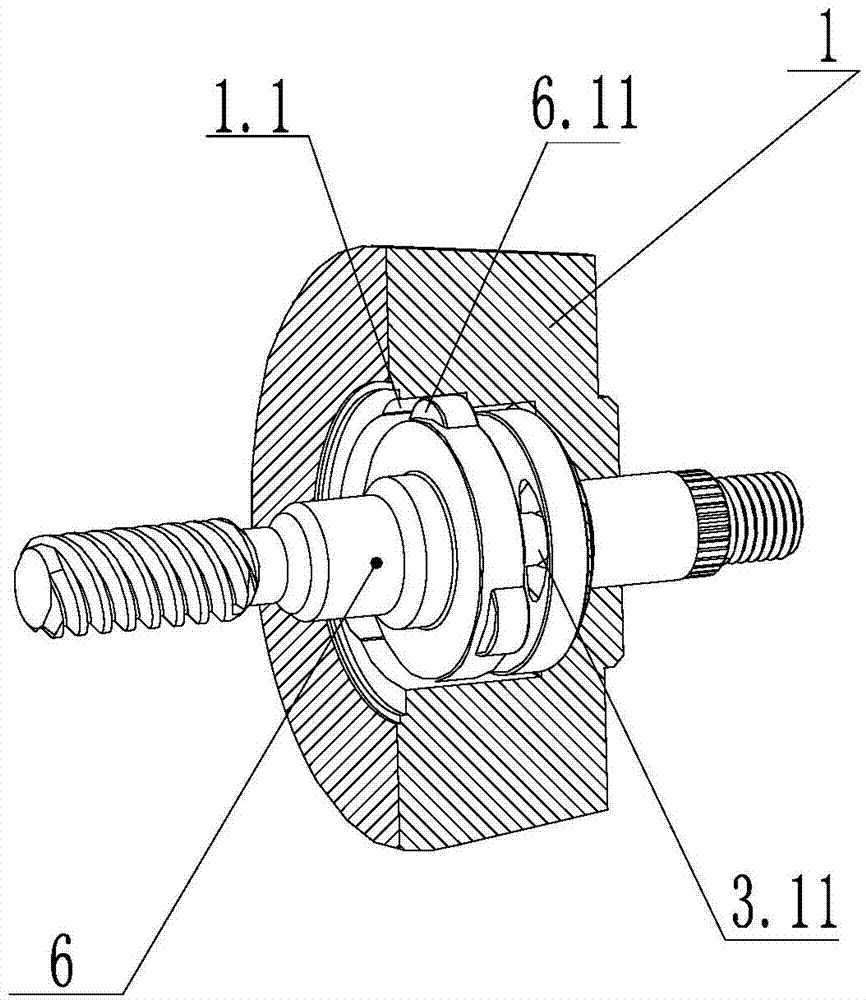

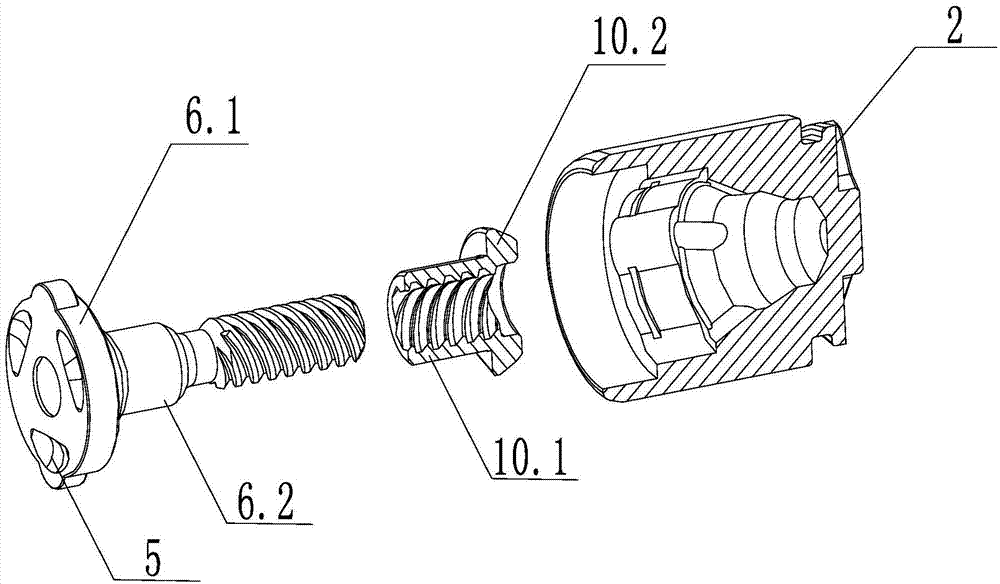

[0042]As shown in the figure: the disc brake cylinder assembly with parking mechanism includes a hollow housing 1 with openings that gradually become smaller from left to right. Piston 2, stroke adjustment screw 6 and The drive shaft 3; the drive shaft 3 passes through the bottom end of the cylinder hole at the other end of the housing 1 and is connected with the rod arm assembly 4 outside the housing through a straight-tooth spline; the shaft wall between the drive shaft 3 and the rod arm assembly 4 is set Leather cup 18; drive shaft 3 is provided with disc 3.1 at one end in the cylinder body, and the outer surface of disc 3.1 is distributed with a plurality of first slope-shaped fairways 3.11 at the center, and stroke adjustment screw rod 6 is made up of screw rod 6.2 and ball disc 6.1 The overall structure; the ball disc 6.1 of the stroke adjustment screw 6 is provided with a second slope-shaped ballway 5 corresponding to the first slope-shaped ballway 3.11 of the drive shaf...

Embodiment 2

[0053] In this embodiment, the integral parking brake caliper assembly structure including the brake cylinder assembly includes all the structures of the disc brake cylinder assembly in Embodiment 1, and its housing 1 is an integral structure. The body is extended with a claw 19 opposite to the end face of the piston 2, and a friction plate 20 is placed between the piston 2 and the claw 19 to form a clamping space for the brake disc 22. The structure also includes a bracket 21 connecting the housing and the fixed friction plate 20 .

[0054] Its working process is identical with embodiment 1.

Embodiment 3

[0056] This embodiment includes the overlapping combined parking brake caliper assembly structure of the brake cylinder assembly, which includes all the structures of the disc brake cylinder assembly in Embodiment 1, and also includes: bridge plate 23, connection Screw 24 and friction plate 20.

[0057] Its working process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com