Production method of self-repairing super-hydrophobic flame retardation coat layer

A flame-retardant coating and super-hydrophobic technology, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc., can solve the problem that the flame-retardant layer is difficult to withstand the washing process in water and affects the flame-retardant fabric Application and other issues to achieve the effect of preventing loss, prolonging life, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation and flame retardant application of self-healing superhydrophobic flame retardant coating on polyester surface

[0033]Soak polyester successively in PAH aqueous solution (5mg / mL, pH=10) and PA aqueous solution (30mg / mL, pH=5) for 30 minutes each, take out the substrate after each soak, wash the substrate with deionized water and wring it out Moisture in the substrate; dry in an oven at 60°C for 4 hours, and a flame-retardant film is prepared on the surface of the substrate.

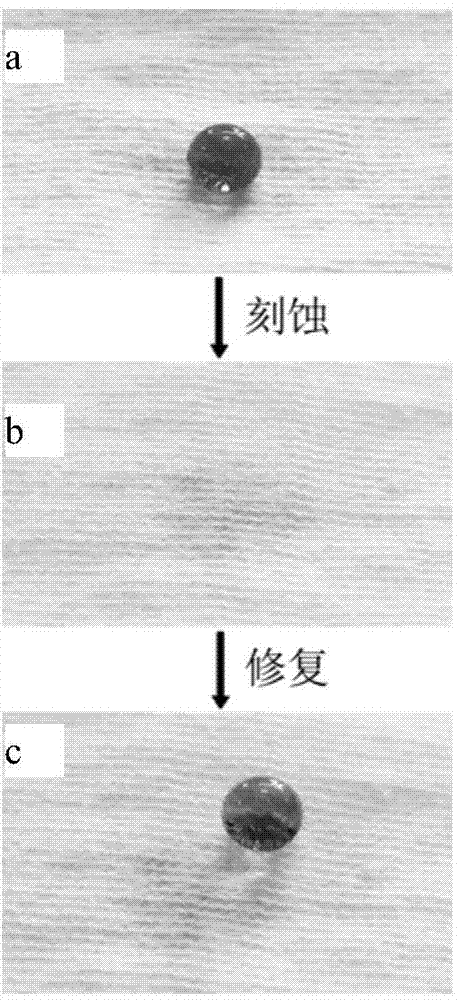

[0034] Soak the dried flame retardant polyester in 5mg / mL CH 3 (CH 2 ) 13 -Poss in a dichloromethane solution for 3 minutes, and then dry to obtain a self-healing superhydrophobic flame-retardant polyester.

[0035] In this example, changing the solution concentration will not have a significant impact on the construction of the membrane, but if the solution concentration is too low and the solute is too small, it will be difficult to obtain a very good fireproof effect an...

Embodiment 2

[0038] Example 2: Preparation of self-healing superhydrophobic flame-retardant coating on the surface of linen and application of self-healing superhydrophobic

[0039] Soak the linen in PDDA aqueous solution (8mg / mL, pH=7) for 20 minutes, then soak in PSP aqueous solution (25mg / mL, pH=7) for 60 minutes, take out the linen after each soaking, and rinse with deionized water Wash the linen and wring out the moisture in the linen; then dry it in an oven at 60° C. for 4 hours to prepare a flame-retardant film on the surface of the linen.

[0040] Soak the dried flame retardant burlap in 3mg / mL CF 3 (CF 2 ) 7 (CH 2 ) 2 -POSS in a toluene solution for 5 minutes, and then dry to obtain a self-healing superhydrophobic flame-retardant burlap.

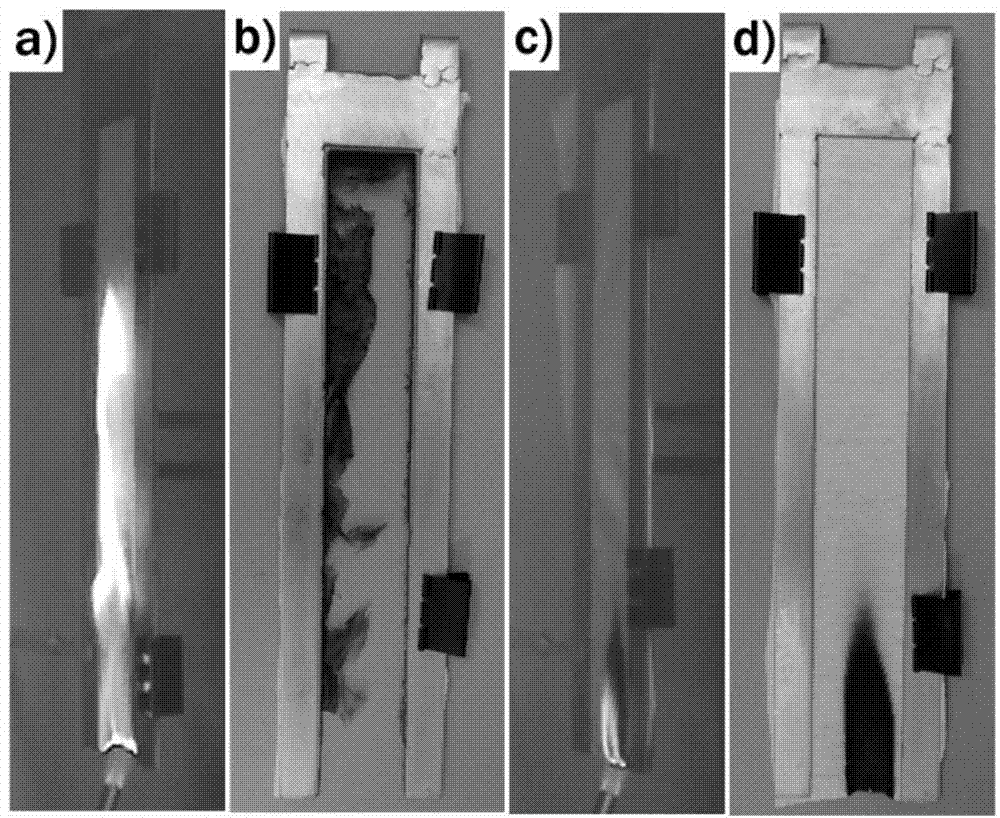

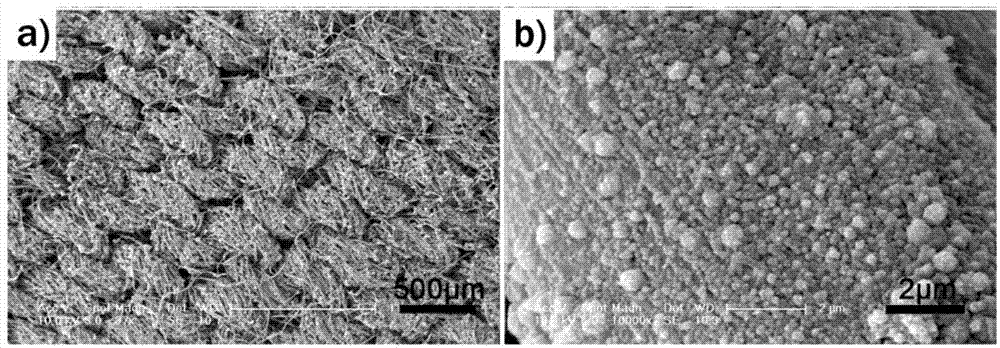

[0041] from image 3 a It can be seen that even after flame baking and carbonization blackening, the integrity of the yarn structure of the fabric can still be maintained, in the enlarged SEM image ( image 3 In b), it can be seen that th...

Embodiment 3

[0043] Example 3: Preparation method of self-healing superhydrophobic flame-retardant coating Applying a composite dual-principle flame-retardant system to cotton cloth

[0044] Soak the cotton cloth in PEI aqueous solution (8mg / mL, pH=9), PSP and MMT composite aqueous solution (PSP concentration is 25mg / mL, pH=7, MMT is 5% of the mass of PSP) each for 20 minutes, each After soaking for the first time, take out the cotton cloth, wash the cotton cloth with deionized water and wring out the water in the substrate; dry it in an oven at 50°C for 5 hours, and prepare a flame-retardant film on the surface of the cotton cloth.

[0045] Soak the dried flame retardant substrate in 6mg / mL C 8 h 17 -Poss in a dichloromethane solution for 10 minutes, and then dry to obtain a self-healing superhydrophobic flame-retardant cloth.

[0046] In the composite system of PSP and MMT, there is both an intumescent flame retardant mechanism and a physical barrier effect of MMT. When the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com