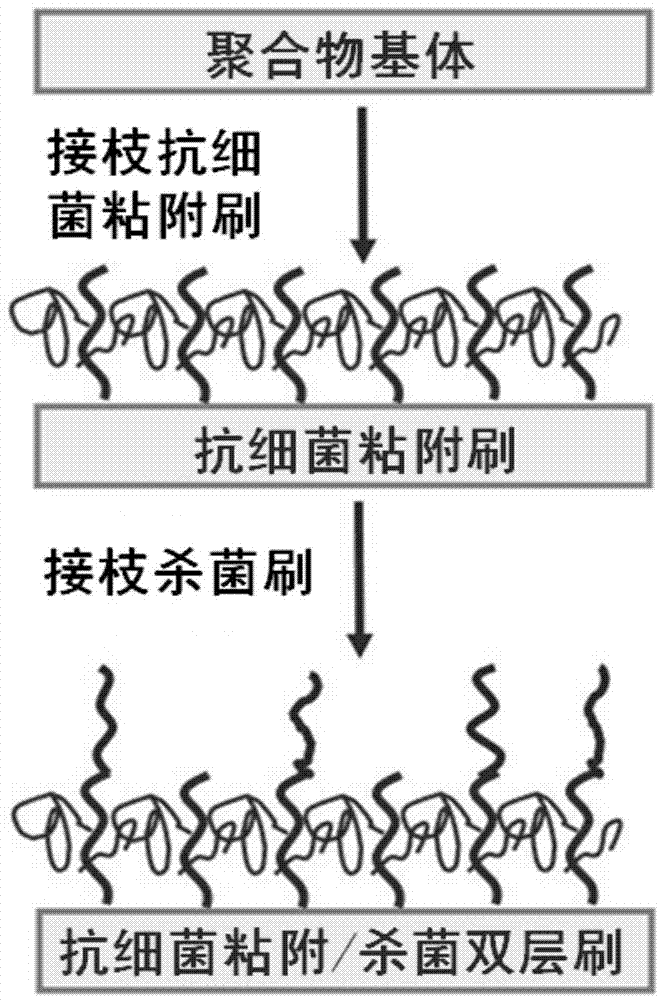

Method for preparing antibacterial surface on medical high polymer material surface

A polymer material and surface modification technology, applied in the field of preparing antibacterial surfaces, can solve the problems affecting the surface antibacterial performance, antibacterial adhesion ability and sterilization ability, etc., to avoid mutual interference of performance, excellent biocompatibility, excellent The effect of long-lasting antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Plasma pretreatment of medical polypropylene film, the working parameters are: power 90W, pressure 30Pa, gas flow rate 30cc / min, temperature 30°C, time 2min; then the sample was placed in 5.0wt% p-chloromethylbenzoyl chloride In an anhydrous solution, react at 25°C for 8h; then place the sample in an ethanol solution of 10.0wt% sodium diethyldithiocarbamate, and react at a reaction temperature of 30°C for 24h; then place the sample at 15.0wt% In the aqueous solution of monopolyethylene glycol acrylate, a 300W high-pressure mercury lamp was irradiated for 6 minutes; then the sample was washed with ethanol and deionized water for 25 minutes successively under the condition of oscillating in a water bath with a frequency of 120; then the sample was placed in 10.0wt% methacrylic acid In the aqueous solution of amide group quaternary ammonium salt, 300W high-pressure mercury lamp irradiates 4min, finally on the surface of medical polypropylene film, the antibacterial surface ...

Embodiment 2

[0045] Perform plasma pretreatment on the surface of medical polymer materials, and its working parameters are: power 20W, pressure 5Pa, gas flow rate 2cc / min, temperature 10°C, time 10min; then the sample is placed in 2.0wt% p-chloromethylphenyl In an anhydrous isocyanate solution, react at 10°C for 24h; then place the sample in an ethanol solution of 2.0wt% sodium dimethyldithiocarbamate, and react at a temperature of 20°C for 48h; then place the sample in 4.0wt% formaldehyde In the aqueous solution of acryloyloxyphosphorylcholine, a 500W high-pressure mercury lamp was irradiated for 3 minutes; then the sample was washed with ethanol and deionized water for 20 minutes in a water bath with a frequency of 120; then the sample was placed in 2.0wt% methyl In the aqueous solution of acrylamide-based quaternary ammonium salt, a 500W high-pressure mercury lamp is irradiated for 2 minutes, and finally an antibacterial surface co-modified by the bottom layer of the anti-bacterial adhe...

Embodiment 3

[0047] Perform plasma pretreatment on the surface of medical polymer materials, and its working parameters are: power 800W, pressure 120Pa, gas flow rate 500cc / min, temperature 45°C, time 1min; then the sample is placed in 20.0wt% o-chloromethylphenyl In an anhydrous trichlorosilane solution, react at 40°C for 2h; then place the sample in an ethanol solution of 20.0wt% sodium diisopropyldithiocarbamate, and react at a temperature of 50°C for 6h; then place the sample at 60.0 In an aqueous solution of wt% acryloyloxycarboxybetaine, irradiate with a 30W high-pressure mercury lamp for 120 minutes; then the sample was washed with ethanol and deionized water for 30 minutes in a water bath with a frequency of 120; then the sample was placed in a 30.0wt% In the aqueous solution of methacrylamide-based quaternary ammonium salt, 30W high-pressure mercury lamp is irradiated for 40 minutes, and finally an antibacterial surface co-modified by anti-bacterial adhesion brush bottom layer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com