Self-balance multifunctional carrier

A self-balancing, multi-functional technology, applied in the direction of lifting devices, etc., can solve the problems of small ground clearance, long handling time, and labor consumption, so as to achieve the effect of convenient operation, improve security efficiency, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

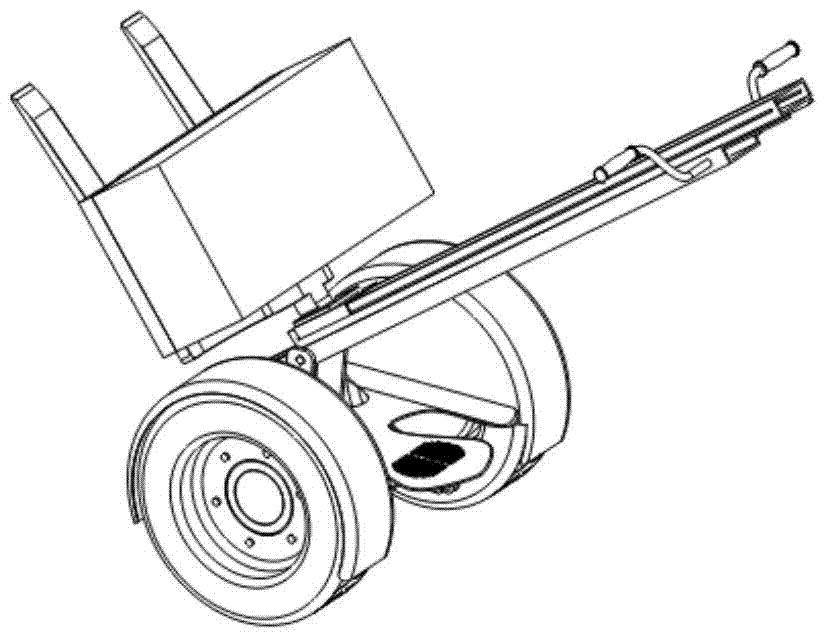

[0034] refer to figure 1, a kind of self-balancing multifunctional transport vehicle of the present invention, comprises car body 3, lifting motor 4, wheel side drive motor 19, two-stage lifting mast articulated frame 17, auxiliary outrigger electric cylinder 1, pedal 2, lithium Ion battery pack 5, articulated two-stage hoisting mast, control handle 7, cargo fork 11, auxiliary outrigger 15, outrigger roller 14, sliding fork mounting bracket 16, driving wheels 13 and 18, and attitude control gyroscope , inclination sensor, mechanical and electrical accessories, motor controller, winch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com