An automobile hydraulic start-stop system

A hydraulic and automotive technology, applied in vehicle components, control devices, brakes, etc., can solve the problems of large recovered energy loss, high manufacturing cost, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

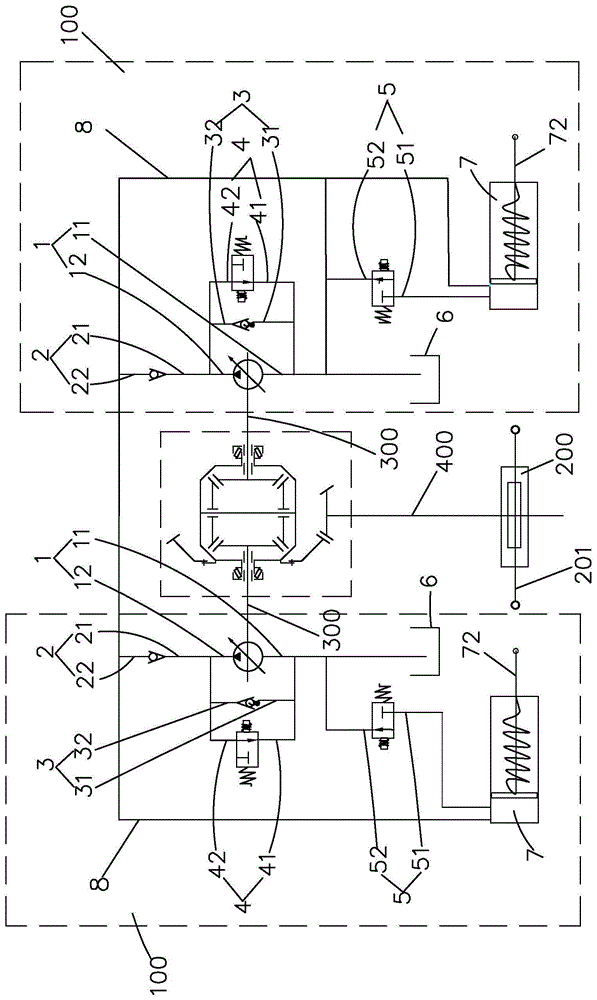

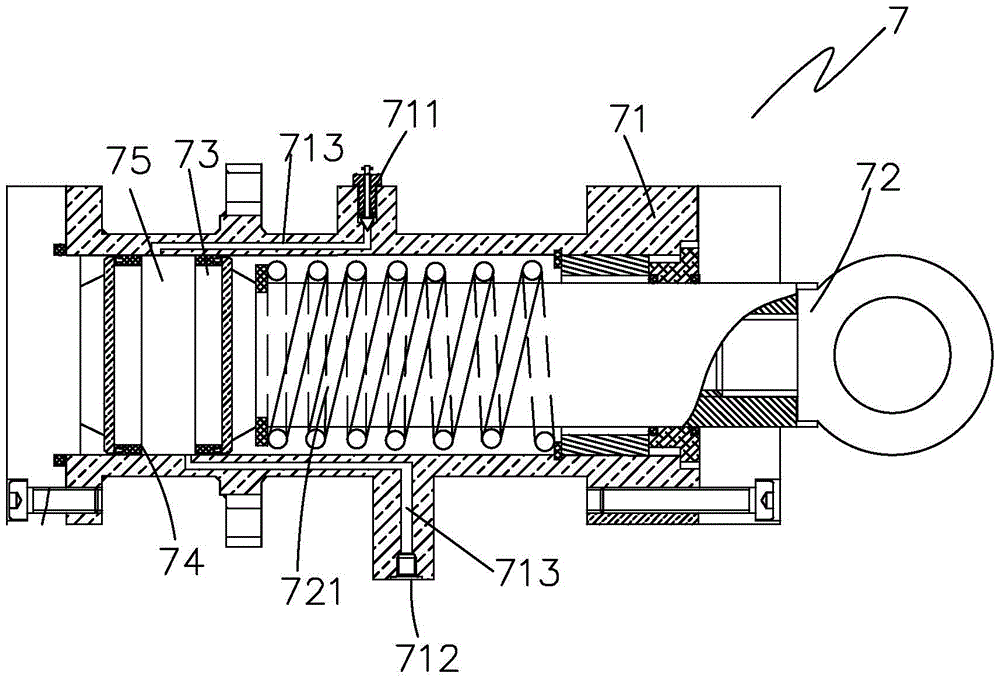

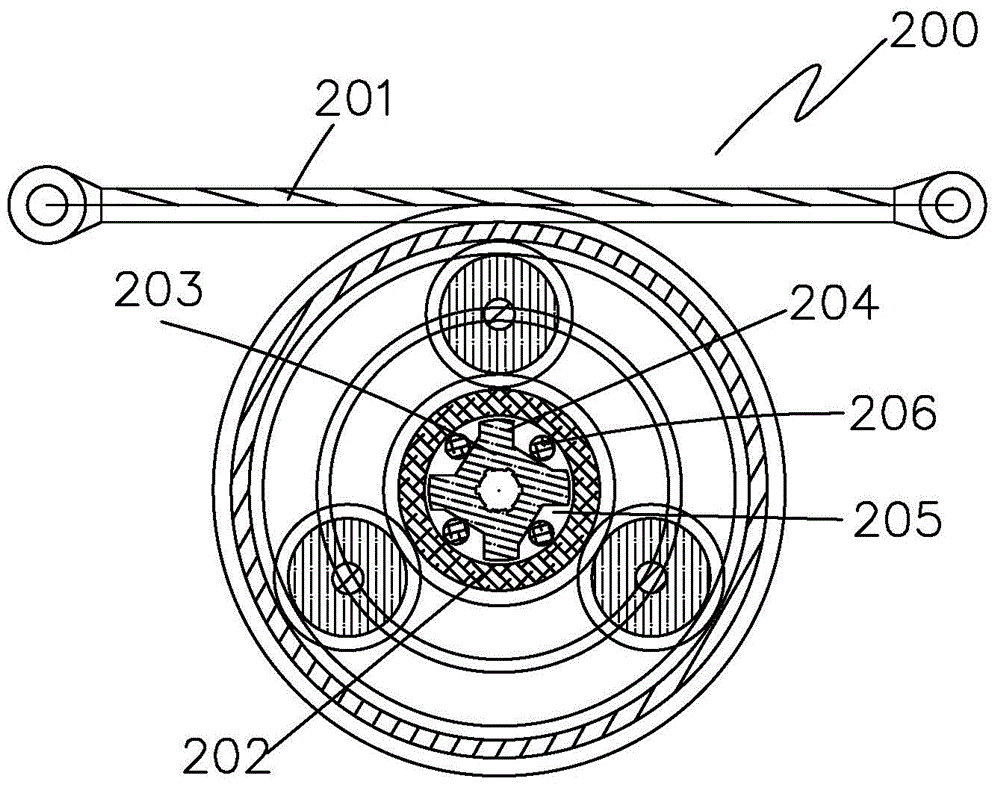

[0039] see figure 1 As shown, the present invention, a hydraulic start-stop system for automobiles, includes two connected hydraulic mechanisms 100 and a planetary gear speed increaser 200, the planetary gear speed increaser 200 is provided with a rack pull rod 201, any The hydraulic mechanism 100 includes: including a hydraulic pump 1, a one-way valve 2, a pressure limiting valve 3, a brake trigger hydraulic solenoid valve 4, a throttle trigger hydraulic solenoid valve 5, an oil storage cylinder 6, a hydraulic cylinder 7 and a plurality of hydraulic pipelines 8. Both sides of the cylinder body 71 of the hydraulic cylinder 7 are respectively provided with an oil pressure pipe oil inlet port 711 and an oil pressure pipe oil return port 712. Inside the cylinder body 71 of the hydraulic cylinder 7 A push rod 72 is provided;

[0040] The connection method is as follows: the hydraulic pump 1 is connected to the vehicle driving wheel half shaft 300 through a spline (not shown), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com