A slag oil press

A technology of oil press and slag, which is applied in the field of oil press, which can solve the problems of potential safety hazards, injury to operators, and failure of oil to be thrown out, etc., and achieves the effects of convenient operation assistance, convenient movement, and easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

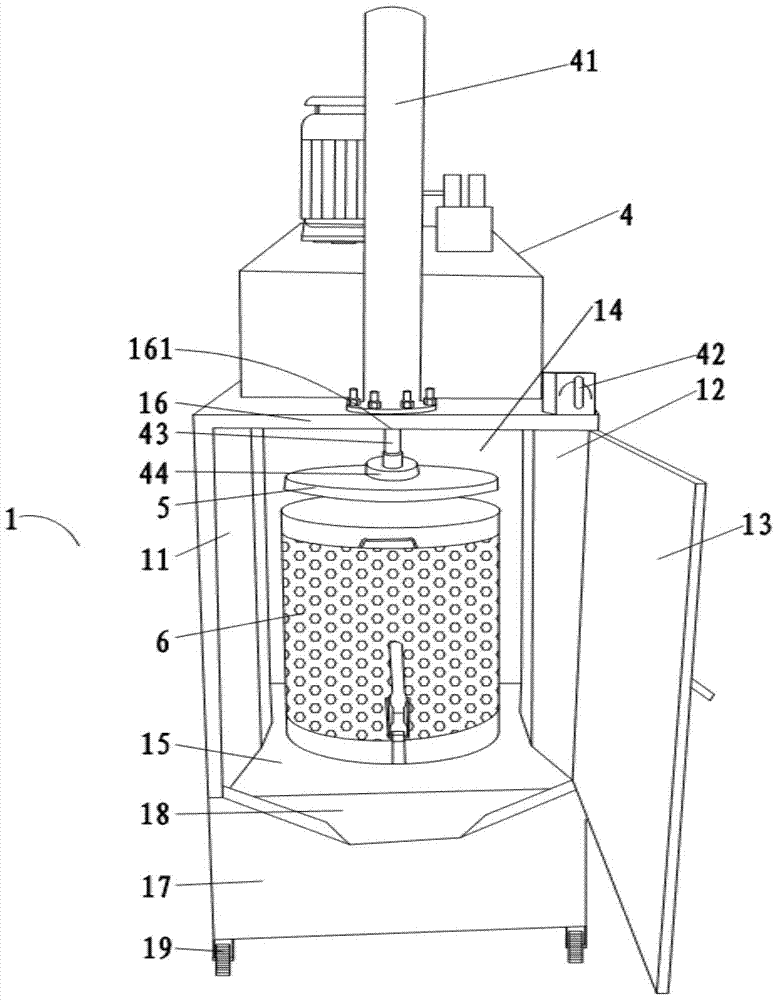

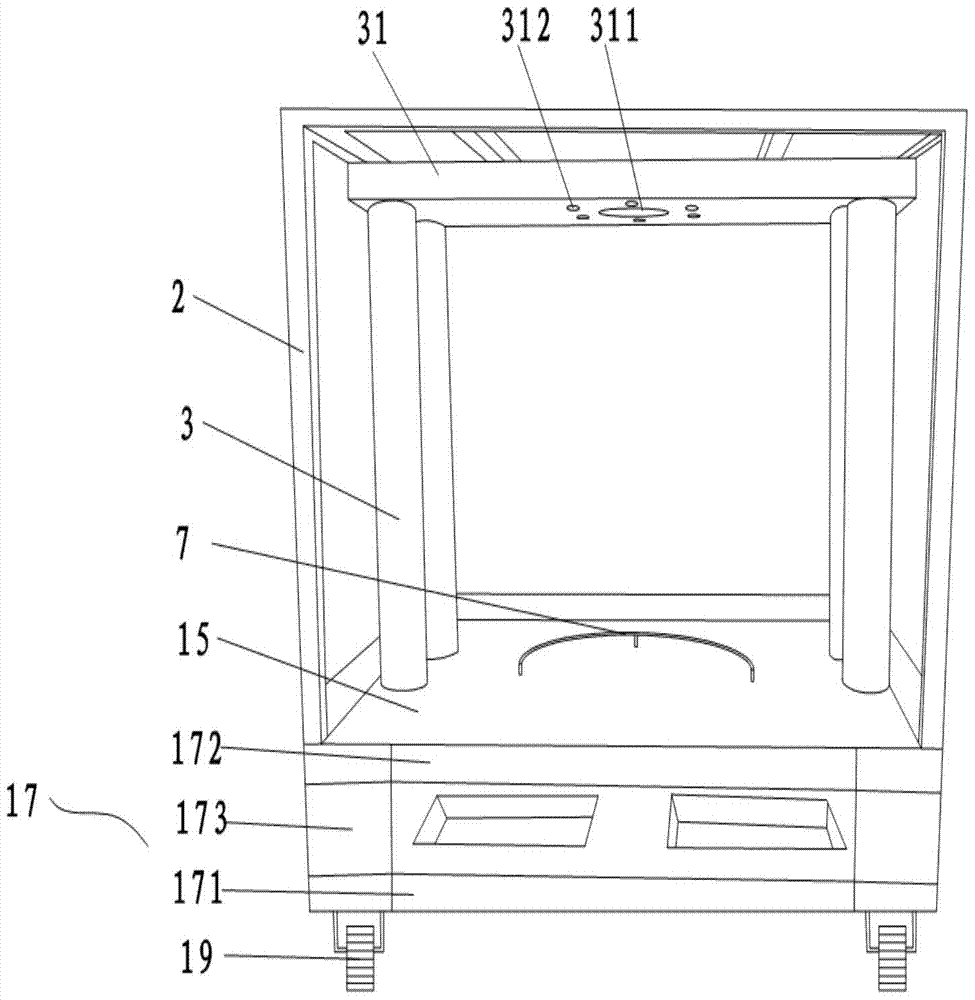

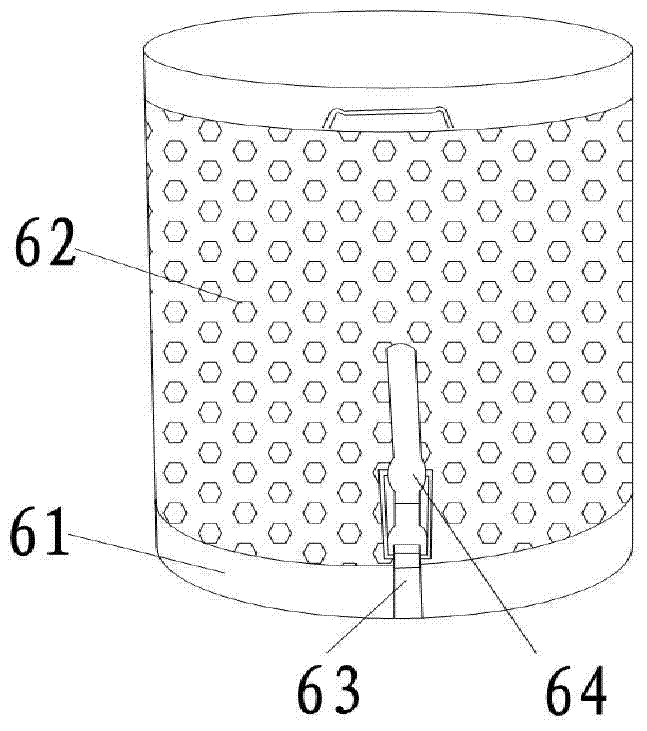

[0033] Such as Figure 1-3 As shown, the slag oil press provided by the present invention includes a box body 1, and the box body 1 includes a left side wall 11, a right side wall 12, a front wall 13, a rear wall 14, a bottom plate 15, and a top plate 16; A bottom support 17 is provided, and a downwardly inclined oil outlet bucket 18 is provided on the front edge of the bottom plate 15 .

[0034] The left side wall 11 and the right side wall 12 have the same structure and are centrally symmetrical, wherein the left side wall 11 includes two square tubes 2 arranged at both ends of the left side of the bottom plate 15 and connected to the top plate 16, and arranged on the bottom support 17. and the two steel columns 3 between the top plate 16, and the stainless steel plate wrapped around the square pipe 2 and the steel column 3; The bottom edge is the left side of the base plate 15, the two ends of the short bottom edge are the sections of the two steel columns 3, and the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com