Motor for tower-type pumping unit and tower-type pumping unit thereof

A tower-type pumping unit and electric motor technology, which is applied to electromechanical devices, electrical components, and electric components, etc., can solve the problems of gear lubricating oil being easily solidified into solid, unable to be maintained, and gear protection and lubricating effect being reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

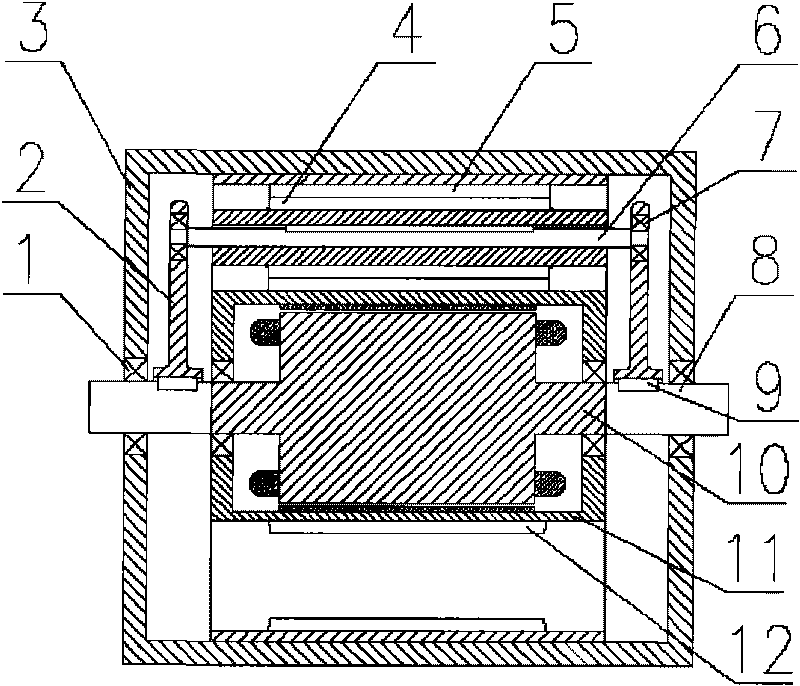

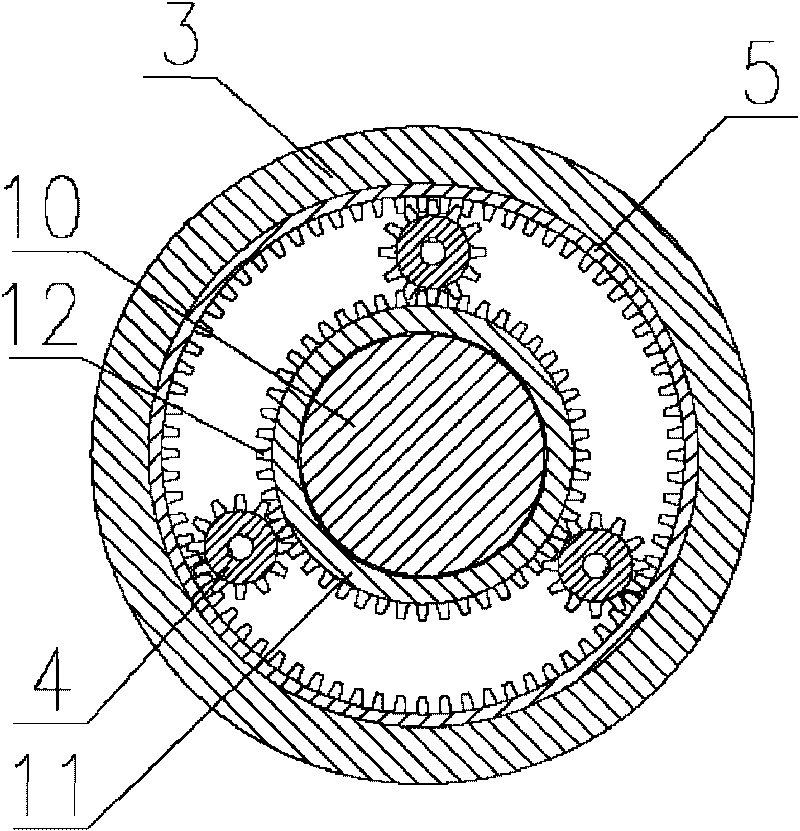

[0022] attached Figure 1-2 It is the best embodiment of the motor for the tower pumping unit of the present invention;

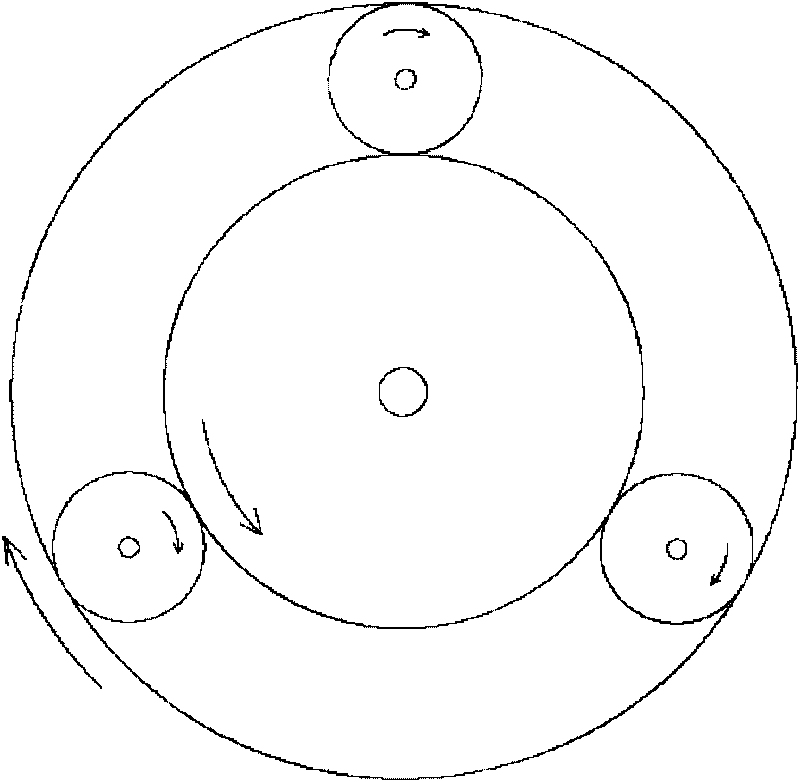

[0023] attached Figure 3-5 It is the best embodiment of the tower pumping unit of the present invention.

[0024] The specific technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] attached Figure 1-2 It is the motor for the tower pumping unit of the present invention, the driving device composed of the inner planetary gearbox and the motor, each gear adopts a superimposed transmission, and it includes a bearing 1, a gear bracket 2, a gear bracket 3, a pinion 4, Big gear 5, shaft 6, bearing 7, outer rotor motor 8, key 9, outer rotor motor stator 10, motor outer rotor 11, gear 12, wherein,

[0026] The outer rotor motor 8 is externally provided with a motor outer rotor 11,

[0027] The gear 12 is nested on the outer rotor 11 of the motor,

[0028] Several small gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com