Tool wear monitoring system based on current and sound emission composite signals

An acoustic emission signal and current signal detection technology, which is applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem of low stability and reliability of acoustic emission signal monitoring, and achieve high recognition accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in combination with specific embodiments.

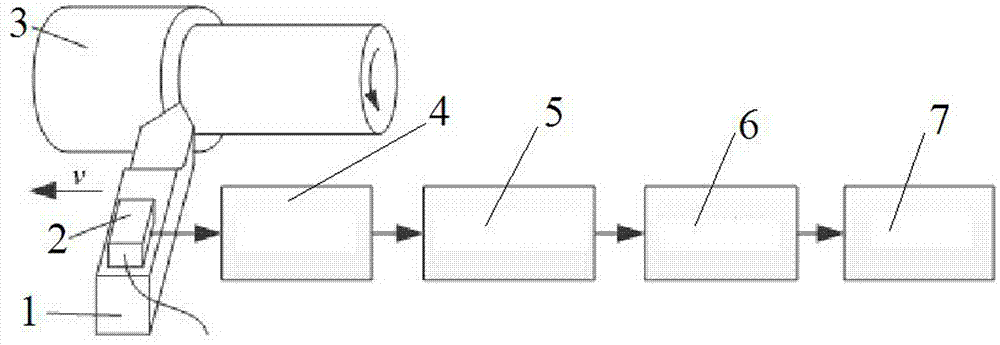

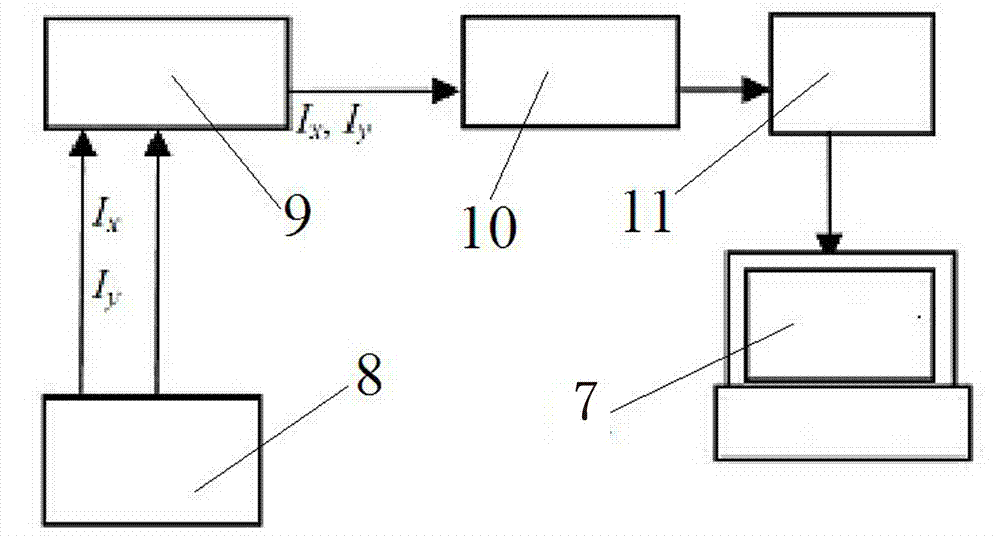

[0033] A tool wear monitoring system based on current and acoustic emission composite signals, characterized in that the system includes a current signal detection mechanism and an acoustic emission signal detection mechanism, and the current signal detection mechanism includes a current sensor 9 and a current amplification and filtering device 10 , A / D converter II 11 and computer 7, the current sensor 9 monitors the current of the machine tool spindle motor 8, the current signal is passed through the current amplification filter device 10, then converted by the A / D converter II 11, and stored by the computer 7 for subsequent processing and Analysis; the acoustic emission signal detection mechanism includes an acoustic emission sensor 2, a signal amplifier 4, an anti-aliasing filter 5, an A / D converter 16 and a computer 7, and the acoustic emission sensor 2 is directly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com