Brake chamber and method for detecting braking action relief of brake chamber

A technology of brake air chamber and braking action, applied in the direction of hydraulic brake transmission device, brake safety system, etc., can solve the problems of parking brake not being released, push rod pushing out, pipeline bending, etc., to achieve comprehensive Detection and accurate judgment, not easy to damage, avoid the effect of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

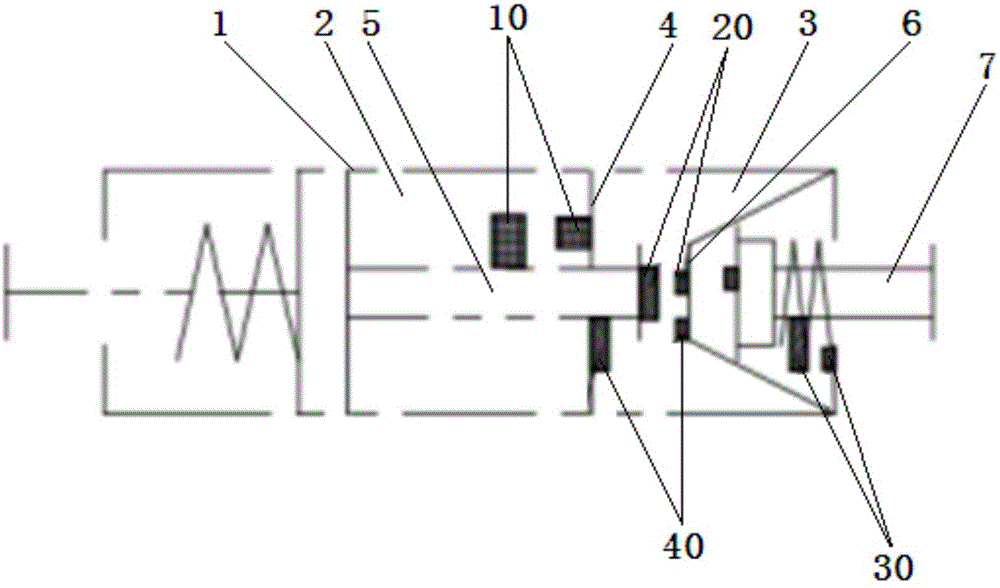

[0039] Such as figure 1 The shown brake air chamber is an energy storage spring brake air chamber, which includes a first housing 1, a parking brake air chamber 2 located in the first housing 1 and a first service brake air chamber 3 located in The partition 4 between the parking brake chamber 2 and the first service brake chamber 3, the push rod 5 passing through the partition 4, and the first diaphragm 6 and the first diaphragm 6 located in the first service brake chamber 3 A push rod 7; the front end of the push rod 5 is located in the first service brake air chamber 3, and keeps a distance from the first diaphragm 6; the rear end of the push rod is located in the parking brake air chamber 2; the first A push rod 7 passes through the first casing 1 .

[0040] The energy storage spring brake air chamber can realize both service braking and parking braking.

[0041] Parking brake test for stored-energy spring brake chambers:

[0042] 1) The first position detection device ...

Embodiment 2

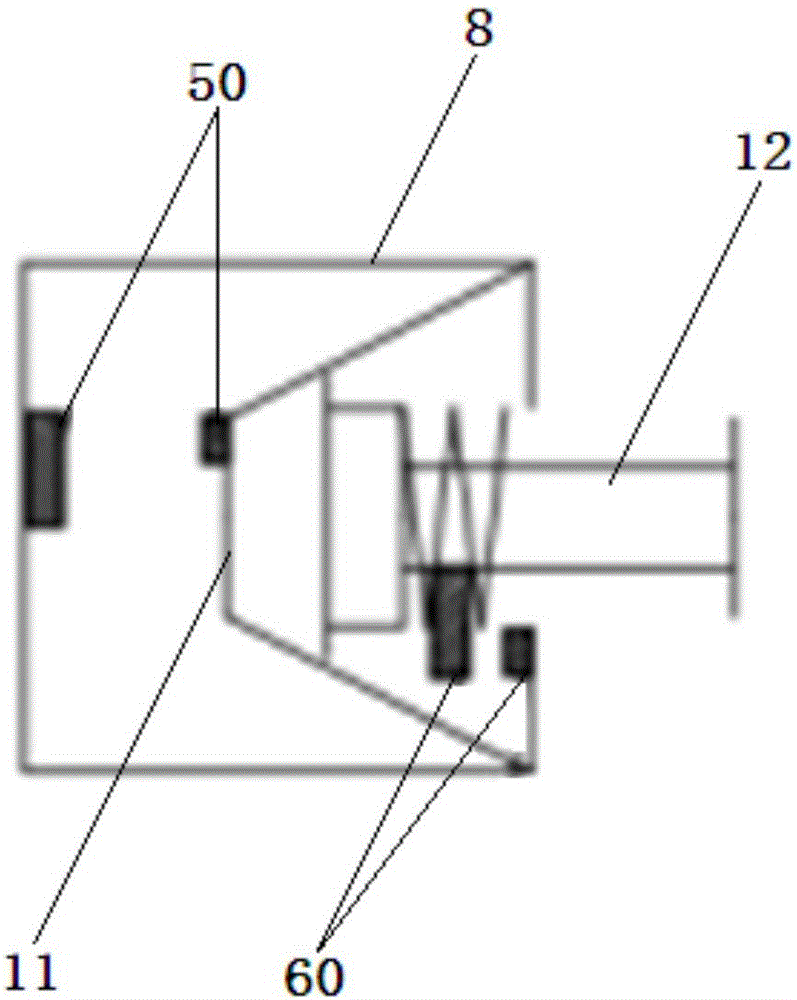

[0052] Such as figure 2 The brake air chamber shown is a diaphragm brake air chamber, which includes a second housing 8, a second service brake air chamber 9 located in the second housing 8, and a second service brake air chamber 9 located in the second housing 8. The second diaphragm 11 and the second push rod 12 inside; the second push rod 12 passes through the second casing 8 .

[0053] The diaphragm brake air chamber can only realize service braking, and its service brake detection is:

[0054] 1) A fifth position detection device 50 is installed in the second service brake air chamber 9 , and the probe and the sensing plate of the fifth position detection device 50 are arranged in pairs on the rod body of the second ejector rod 12 of the second service brake air chamber 9 On the position facing the second housing 8, to detect the third extension distance that the second push rod 12 of the second service brake air chamber 9 extends out of the second service brake air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com