Method of manufacturing CdS/Mg-doped CdSe sensitizer for solar cell

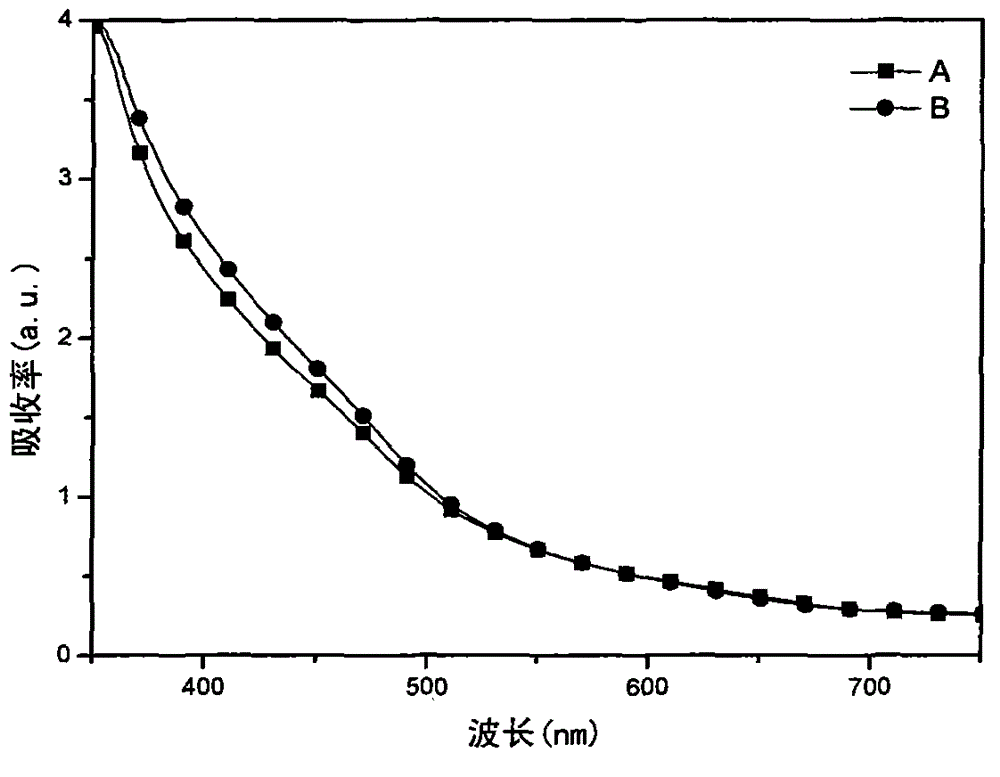

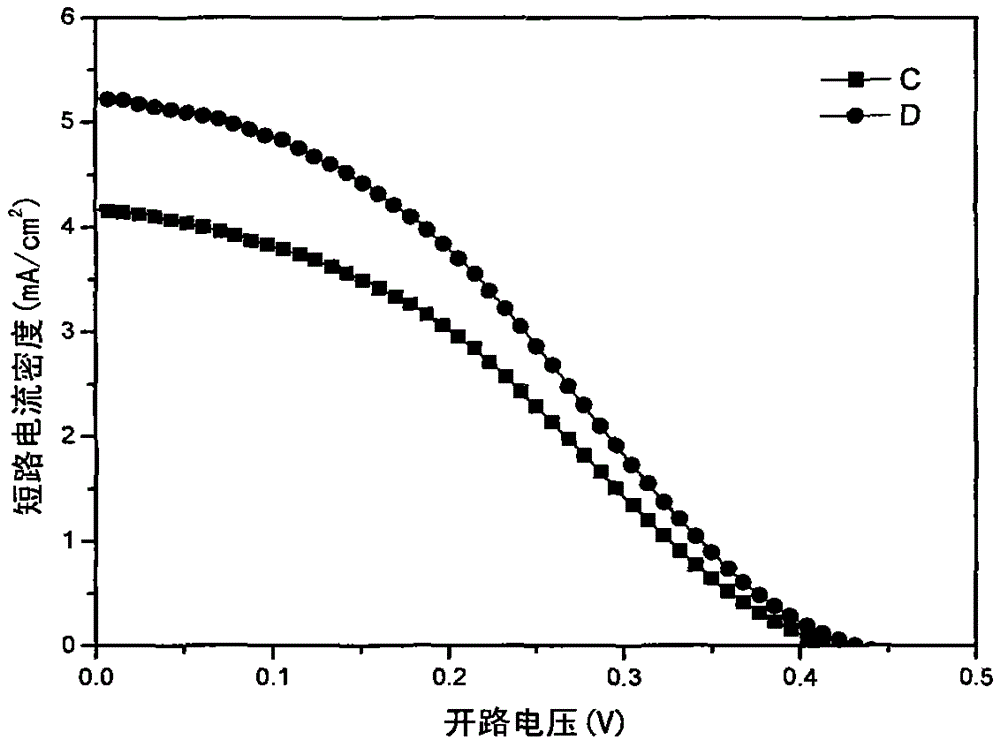

A technology of solar cells and sensitizers, applied in the field of solar energy, to achieve the effects of increased open circuit voltage, rapid separation, and reduced dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific steps of the preparation method of cadmium sulfide / magnesium doped cadmium selenide quantum dot sensitizer are:

[0027] 1) Equipped with Cd(NO at a concentration of 0.1M 3 ) 2 solution and Na 2 S solution, placed in a water bath at 20-50°C for 30-60min;

[0028] 2) the M g Cl 2 ·6H 2O was added to the Cd(NO 3 ) 2 solution, in which Mg 2+ with Cd 2+ The molar concentration ratio is 1:1;

[0029] 3) Put the solution obtained in step 2) into a water bath at 30°C for 30 minutes;

[0030] 4) The photoanode material TiO to be sensitized 2 Immerse the Cd(NO) prepared in step 1) 3 ) 2 In the solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0031] 5) Immerse the photoanode material obtained in step 4) into the Na prepared in step 1) 2 In the S solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0032] 6) Immerse the photoanode material obta...

Embodiment 2

[0035] The specific steps of the preparation method of cadmium sulfide / magnesium doped cadmium selenide quantum dot sensitizer are:

[0036] 1) Equipped with Cd(NO at a concentration of 0.1M 3 ) 2 solution and Na 2 S solution, placed in a water bath at 20-50°C for 30-60min;

[0037] 2) MgCl 2 ·6H 2 O was added to the Cd(NO 3 ) 2 solution, in which Mg 2+ with Cd 2+ The molar concentration ratio is 1:500;

[0038] 3) Put the solution obtained in step 2) into a water bath at 30°C for 30 minutes;

[0039] 4) The photoanode material TiO to be sensitized 2 Immerse the Cd(NO) prepared in step 1) 3 ) 2 In the solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0040] 5) Immerse the photoanode material obtained in step 4) into the Na prepared in step 1) 2 In the S solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0041] 6) Immerse the photoanode material obtained...

Embodiment 3

[0044] The specific steps of the preparation method of cadmium sulfide / magnesium doped cadmium selenide quantum dot sensitizer are:

[0045] 1) Equipped with Cd(NO at a concentration of 0.1M 3 ) 2 solution and Na 2 S solution, placed in a water bath at 20-50°C for 30-60min;

[0046] 2) MgCl 2 .6H 2 O was added to the Cd(NO 3 ) 2 solution, in which Mg 2+ with Cd 2+ The molar concentration ratio is 1:1000;

[0047] 3) Put the solution obtained in step 2) into a water bath at 30°C for 30 minutes;

[0048] 4) The photoanode material TiO to be sensitized 2 Immerse the Cd(NO) prepared in step 1) 3 ) 2 In the solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0049] 5) Immerse the photoanode material obtained in step 4) into the Na prepared in step 1) 2 In the S solution for 5 minutes, take it out, clean it with the corresponding solvent, and dry it with nitrogen;

[0050] 6) Immerse the photoanode material obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com