Small-sized ultra-high-speed motor test loading device

A technology of motor testing and loading device, applied in measuring devices, power measurement, instruments, etc., can solve the problems of motor shafting vibration, shafting vibration, inability to carry out, etc., and achieves a small moment of inertia, no friction loss, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

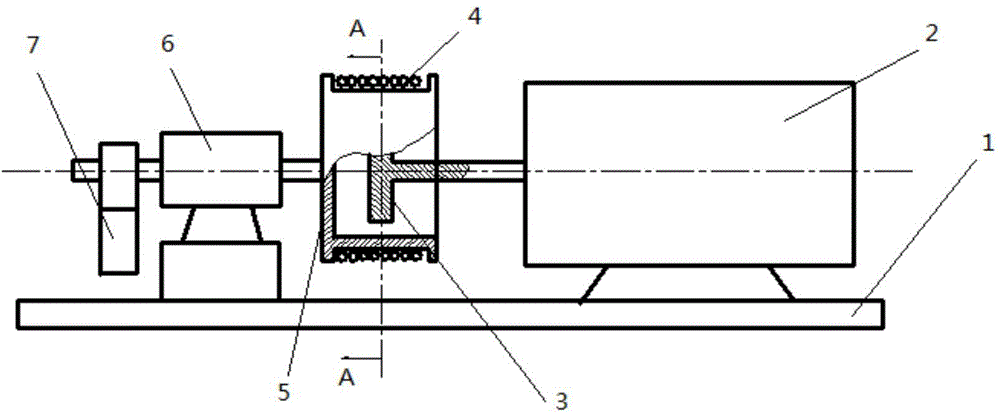

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

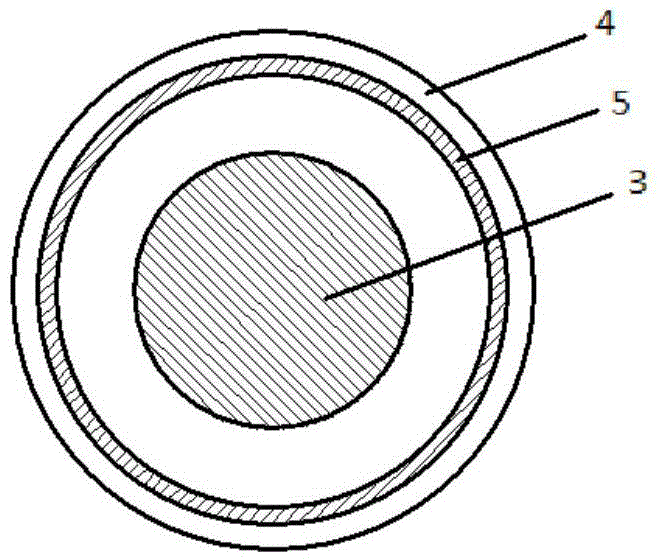

[0023] Such as figure 1 As shown, it is mainly composed of a high-speed rotating eddy current disk 3, a stationary excitation sleeve 5 and a torque detection system. When in use, the eddy current disk 3 is coaxially connected with the output shaft of the motor 2, and the excitation winding 4 of the excitation sleeve 5 is connected to an adjustable DC power supply. The induced current in the disk generates braking torque, the magnitude of which is monitored and displayed by the torque detection system, combined with the speed detection to obtain the load power. Adjusting the excitation current can easily adjust the load power.

[0024] Such as figure 1 As shown, the eddy current disk 3 is made of non-magnetic conductive materials, such as copper, aluminum, stainless steel, etc., which can reduce the axial force on the motor. The eddy current disk and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com