Buffering device of undercarriage buffering support

A buffer strut and buffer device technology, applied in the field of aircraft, can solve the problems of high requirements on structure and materials, difficult to adjust in a large range, limited adjustment range, etc., and achieve the effects of easy implementation, simple structure and large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

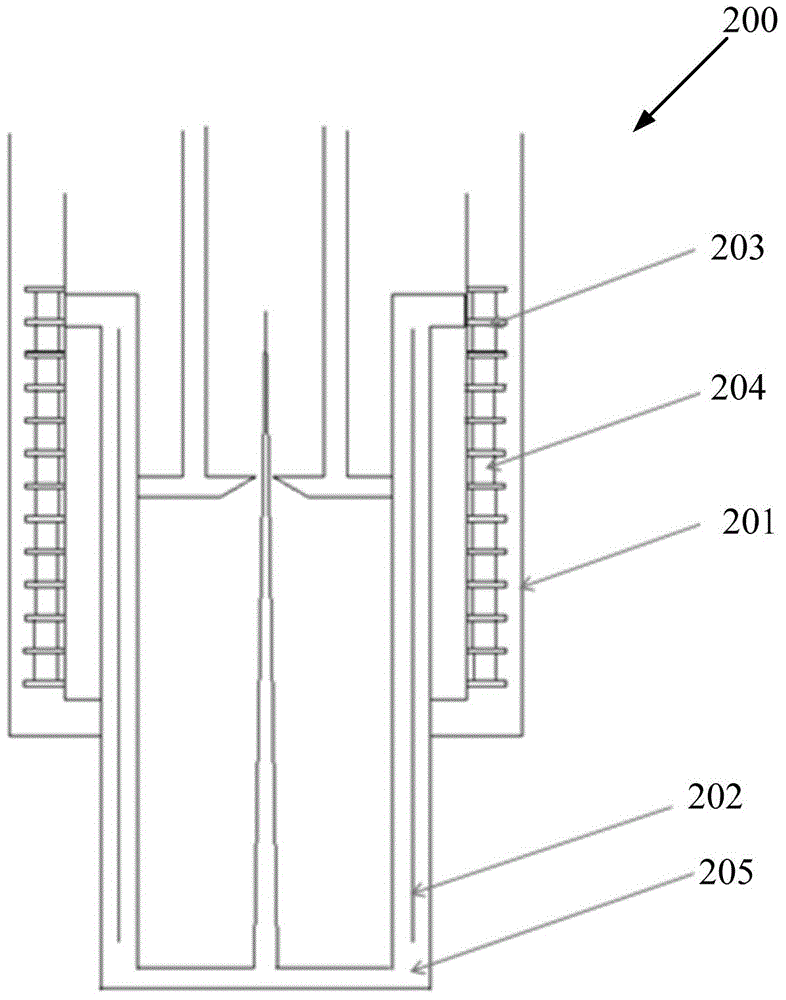

[0027] An embodiment of the buffer device of the landing gear buffer strut according to the present invention is as follows: figure 2 As shown, its typical composition includes three parts: the exciting part arranged on the inner side of the outer cylinder wall of the buffer pillar, the induction part on the inner cylinder of the buffer pillar, and the winding current control unit.

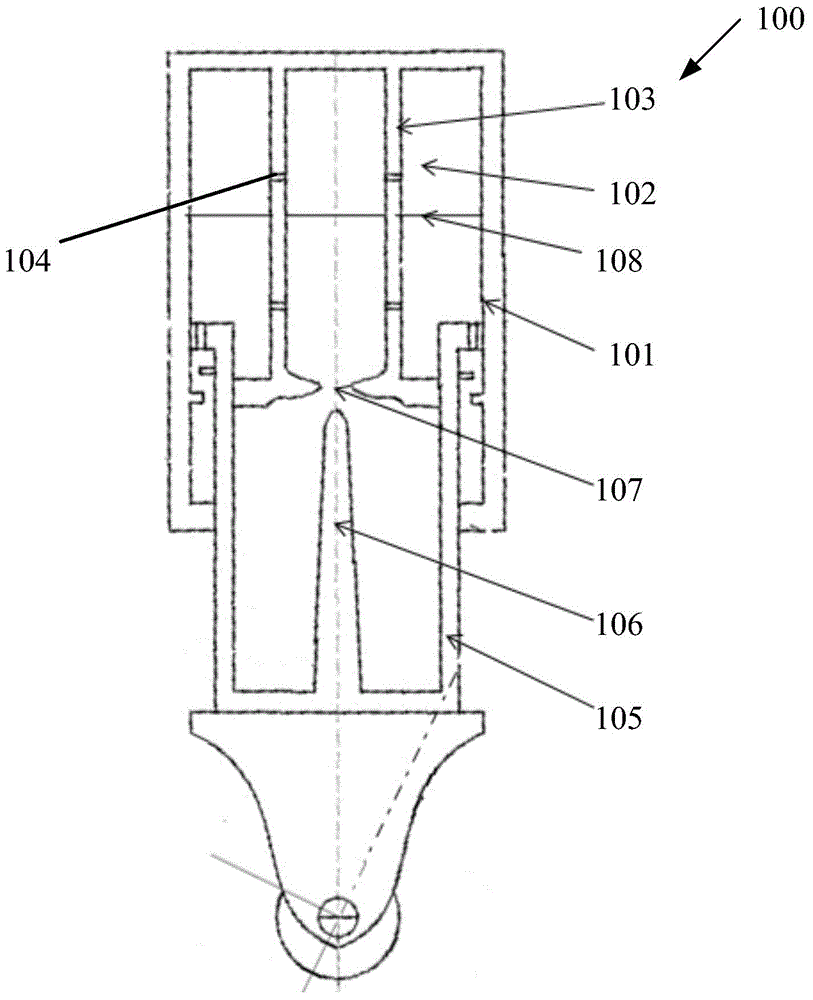

[0028] The buffer device according to the present invention can be applied to various existing buffer strut structures, especially oil-pneumatic buffer struts. compared to figure 1 The existing buffer strut 100 shown, in the improved buffer strut 200 of the present invention, the inner side of the outer cylinder wall 201 of the buffer strut is equipped with an exciting component, and a sensing component is installed at the lower end of the buffer strut, such as a displacement sensor ( not shown). The excitation components are mainly composed of silicon steel sheets 203 and three-phase windings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com