Method for extracting profiling feature parameters of aeronautical blade based on central axis

An aviation blade and parameter extraction technology, which is applied to the extraction of aviation blade profile feature parameters and the field of determining the blade section profile feature parameters, can solve the problems of wrong feature parameter extraction results and low accuracy of mid-arc extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

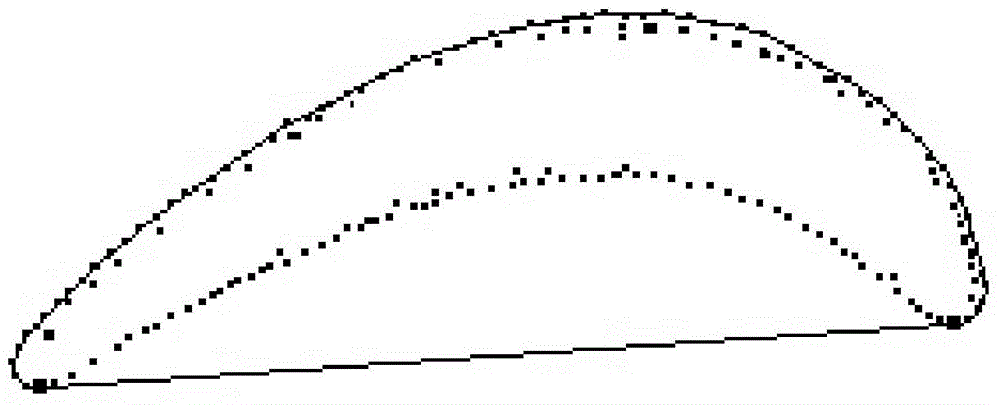

[0066] In the production and reprocessing of aviation blades, extremely strict testing methods must be used to make the blades qualified, and the testing quality of the blade profile has a decisive impact on the performance of the engine. Therefore, it is of great value and significance to extract blade profile parameters with high precision. According to the shape of the blade section, the blade section can be divided into several regions, such as the leading edge, the trailing edge, the blade basin, the blade back, etc. This partition method follows the conventional partition method in this field (for example, refer to Peng Zhiguang, based on the improved convex Extraction of characteristic parameters of blade surface with package algorithm, "Equipment Manufacturing Technology" 2012 No. 1, p. 37).

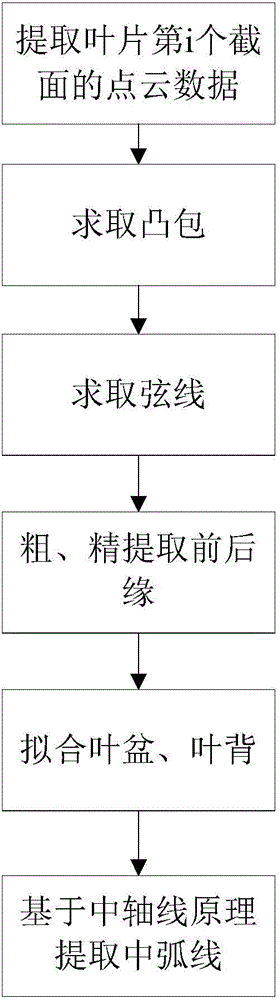

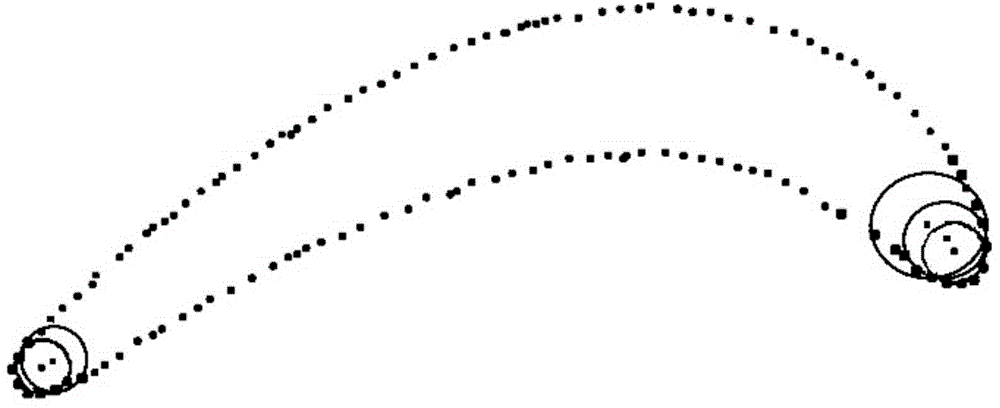

[0067] The invention firstly performs fitting encryption on the back of the blade basin of the aviation blade, and then uses the encrypted curve as a boundary curve, and uses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com