A kind of composite chemical dust suppressant and preparation method thereof

A compound dust suppressant technology, applied in the field of dust suppressant, can solve problems such as poor application effect, single dust suppressant, complex preparation process, etc., achieve environment-friendly dust suppression effect, high industrialization feasibility, and excellent preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Composite chemical dust suppressant of the present invention is made up of the raw material of following percentage by weight:

[0022] Polyethylene glycol 40005%, sodium sulfate 1%, polyvinyl acetate 2%, gelatin 11%, starch 70%, sodium polyacrylate 1%.

[0023] The concrete steps of the preparation method of composite chemical dust suppressant of the present invention are as follows:

[0024] (1) take raw materials by proportioning;

[0025] (2) Freeze-dry polyethylene glycol 4000 at ultra-low temperature from -40°C to -30°C, and crush it with a powerful pulverizer. Start for 10 minutes, rest for 5 minutes, repeat 3 times.

[0026] (3) All the raw materials weighed are added in the pulverizing mixer, the machine is turned on and pulverized for 10 minutes, then intermittently for 5 minutes, and so repeated 3 times to obtain the composite chemical dust suppressant of the present invention.

Embodiment 2

[0028] Composite chemical dust suppressant of the present invention is made up of the raw material of following percentage by weight:

[0029] Polyethylene glycol 400045%, sodium sulfate 10%, polyvinyl acetate 10%, gelatin 5%, starch 15%, sodium polyacrylate 5%.

[0030] The concrete steps of the preparation method of composite chemical dust suppressant of the present invention are as follows:

[0031] (1) take raw materials by proportioning;

[0032] (2) Freeze-dry polyethylene glycol 4000 at ultra-low temperature from -40°C to -30°C, and crush it with a powerful pulverizer. Start for 10 minutes, rest for 5 minutes, repeat 3 times.

[0033] (3) All the raw materials weighed are added in the pulverizing mixer, the machine is turned on and pulverized for 10 minutes, then intermittently for 5 minutes, and so repeated 3 times to obtain the composite chemical dust suppressant of the present invention. 30s, so repeated 3 times, the composite chemical dust suppressant of the pres...

Embodiment 3

[0035] Composite chemical dust suppressant of the present invention is made up of the raw material of following percentage by weight:

[0036] Polyethylene glycol 400015%, sodium sulfate 10%, polyvinyl acetate 20%, gelatin 10%, starch 30%, sodium polyacrylate 5%.

[0037] The concrete steps of the preparation method of composite chemical dust suppressant of the present invention are as follows:

[0038] (1) take raw materials by proportioning;

[0039] (2) Freeze-dry polyethylene glycol 4000 at ultra-low temperature from -40°C to -30°C, and crush it with a powerful pulverizer. Start for 10 minutes, rest for 5 minutes, repeat 3 times.

[0040] (3) All the raw materials weighed are added in the pulverizing mixer, the machine is turned on and pulverized for 10 minutes, then intermittently for 5 minutes, and so repeated 3 times to obtain the composite chemical dust suppressant of the present invention.

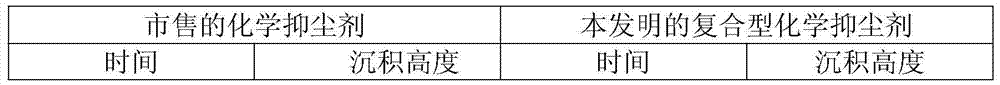

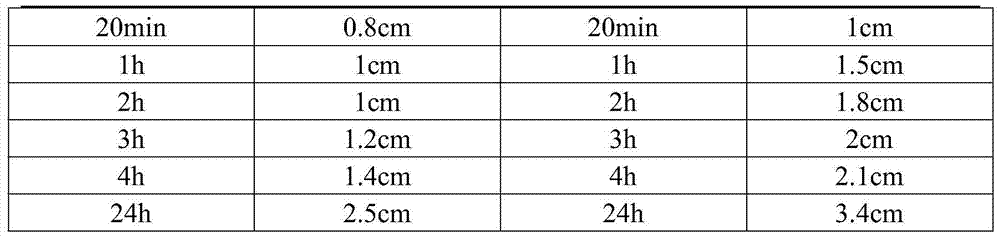

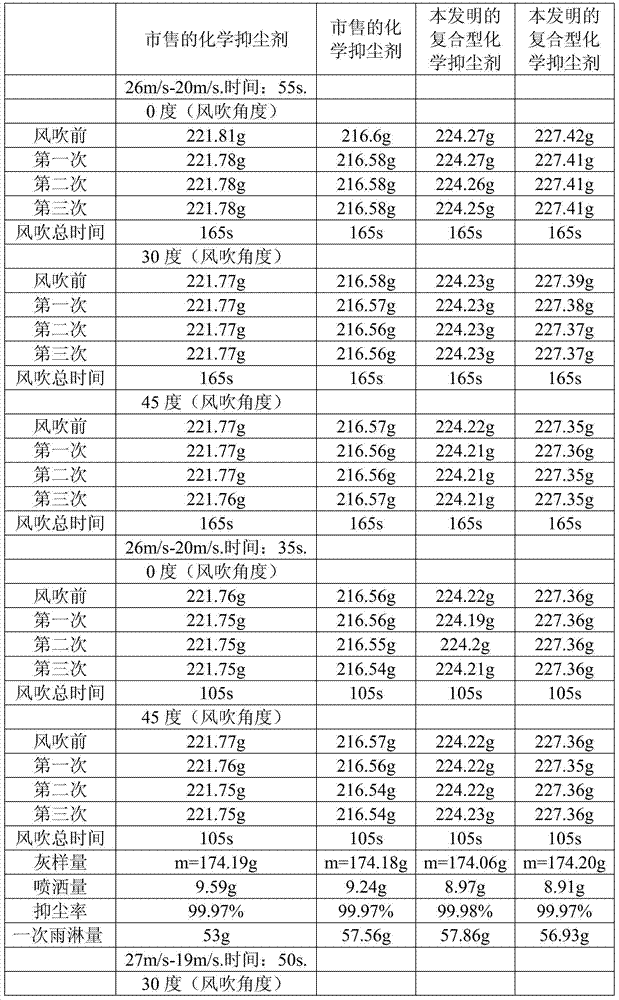

[0041] A commercially available chemical dust suppressant was made into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com