Method for adhesively connecting target and backboard

A connection method and target technology, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult target welding operation, increased leveling process, large thermal stress, etc., so as to avoid thermal deformation and meet the Connection requirements, effect of low connection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

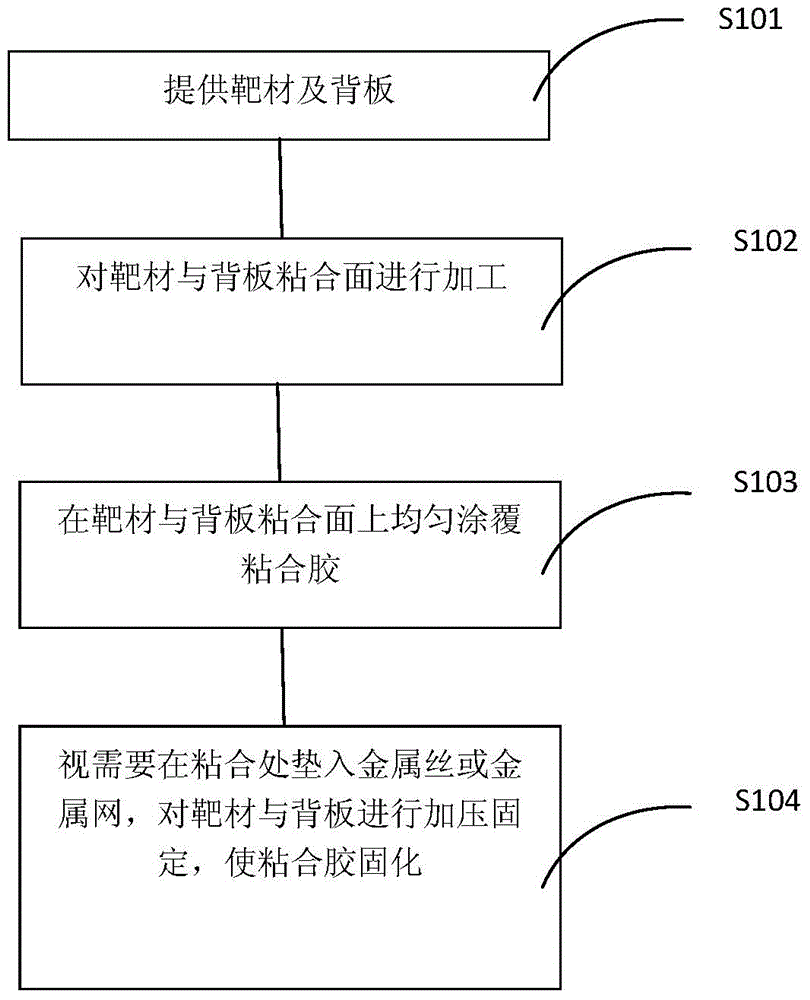

[0032] The present invention provides a method for adhesively connecting a target material and a backplane, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 As shown, step S101 is executed to provide a target material and a back plate;

[0034] Execute step S102 to process the bonding surface of the target material and the back plate;

[0035] The metal target can be sandblasted or machined on the bonding surface, and the non-metallic target can be sandblasted as required.

[0036] Execute step S103, apply adhesive glue on the bonding surface of the target material and the back plate, so that the bonding surface is evenly covered with a thin layer of adhesive glue;

[0037] Execute step S104, pad metal wire or metal mesh at the bonding place if necessary, pressurize and fix the target material and the back plate, and cure the adhesive glue to complete the bonding operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com