Production method of modified aluminum powder

A manufacturing method and technology of aluminum powder, applied in the field of aluminum powder, can solve the problems of low yield rate of end products, poor thermal and electrical conductivity, low thermal and electrical conductivity, etc., to ensure thermal and electrical conductivity, long service life, and improved combination efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

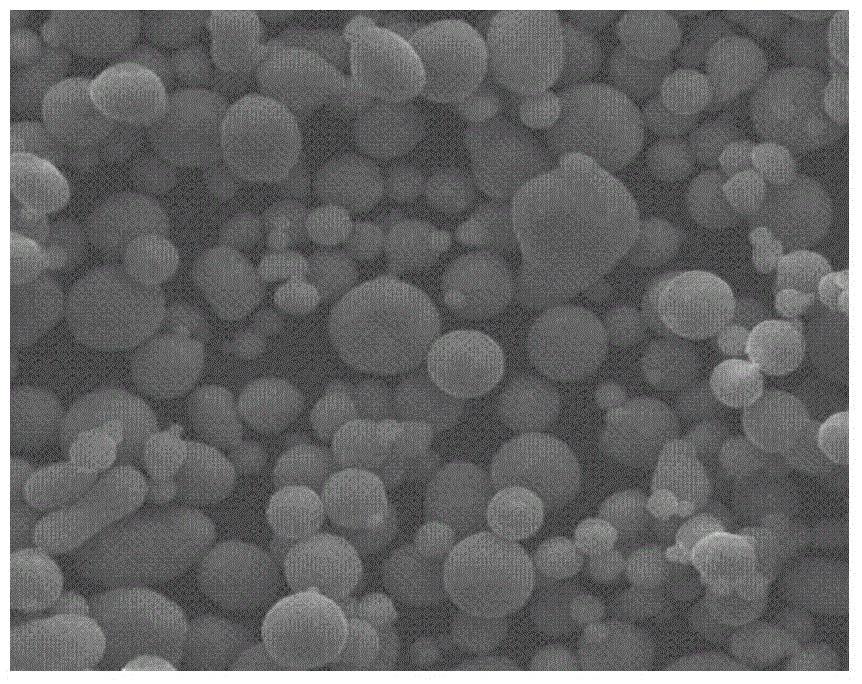

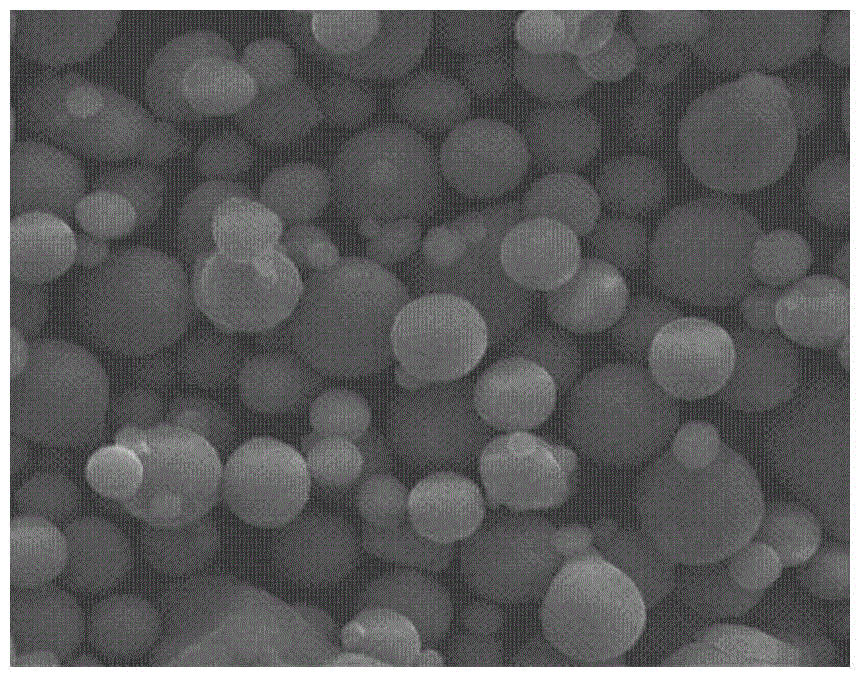

[0013] Such as figure 1 with figure 2 Shown, the manufacture method of a kind of modified aluminum powder of the present invention, comprises the following steps and finishes:

[0014] 1) Put the aluminum powder on the dense steel wire mesh with a density of more than 400 mesh in the drying box. There is a gas transmission connection hole on the lower left side of the drying box, and there are pipes extending into the box inside. The most uniform fumigation of aluminum powder, the water vapor generator can quickly produce water vapor and spray it out evenly. The water vapor is heated, evaporates upwards, and is distributed on the surface of the aluminum powder particles. Adjust the heating temperature according to the amount of water vapor to ensure that the ambient humidity is 75%-85%. At the same time as the water vapor is input, the drying oven i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com