All-solid-state variable-frequency induction heating device for isothermal forging upper and lower molds and heating method

An induction heating device and induction heating furnace technology, applied in forging/pressing/hammer devices, heating/cooling equipment, forging furnaces, etc., can solve problems such as power oscillation, over-melting damaged molds, magnetic field interference, etc., and achieve mold heating Uniform, reduce maintenance costs, improve the effect of heating thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

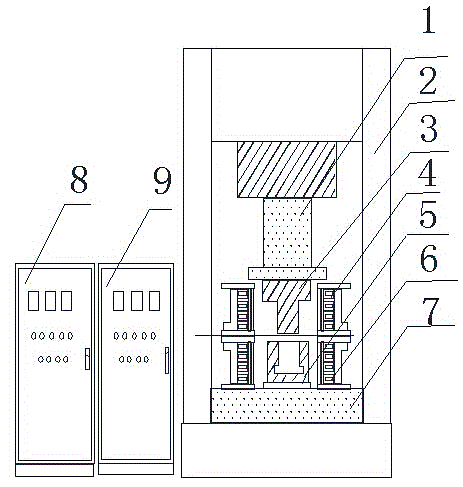

[0015] Control attached figure 1 , φ900mm-φ2000mm isothermal forging upper and lower mold all-solid frequency conversion induction heating device, its structure includes hydraulic press upper die head 1, hydraulic press column 2, isothermal forging upper die 3, upper die induction heating furnace 4, isothermal forging lower die 5, lower die induction Heating furnace 6, hydraulic press lower carriage 7, 1# all-solid-state frequency conversion induction power supply 8, 2# all-solid-state frequency conversion induction power supply 9, wherein the hydraulic press upper die head 1 and the hydraulic press lower carriage 7 are respectively fixed on the upper and lower parts of the hydraulic press column 2 The lower part, the lower mold induction heating furnace 6 is installed on the lower carriage 7 of the hydraulic press and can move back and forth with the lower carriage 7 of the hydraulic press and is easy to disassemble. The lower mold induction heating furnace 6 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com