Five-axis linkage machining method for laser engraving machine

A laser engraving machine, five-axis linkage technology, applied in the mechanical field, can solve the problems of seams, error-prone, distortion and deformation, etc., to improve work efficiency, save steps and time, and change the effect of stretching and distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

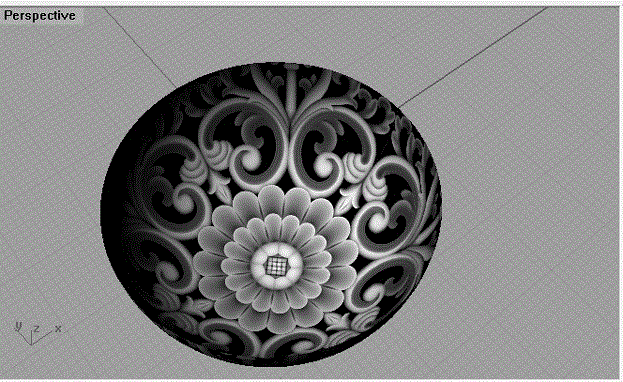

[0037] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the goal is to engrave full patterns on the inner wall of the hemisphere with a diameter of 43.86mm, involving software: computer software GFAC LaserDesign attached to the machine tool, simulation software GFAC Simulator, photoshop, gimp attached to the machine tool , Rhinoceros.

[0038] 1. Modeling. Modeled using Rhinoceros, using rotational molding. See attached Figure 4 , 5 ;

[0039] 2. Create three layers: anti-collision grid (rough grid of the model shape, used for simulating processing and calculating whether it will collide with the machine), positioning grid (determining the processing position) and texture grid (processing content). The texture grid can Copy the positioning grid directly. See attached Figure 6 , 7 ,8;

[0040] 3. Image processing. Since the texture grid is gathered towards the center,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com