Image information detecting method

A detection method and technology of image information, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of large workload, misjudgment, and reduced efficiency of correction algorithms, and achieve improved search efficiency and accurate positioning. Results, the effect of overcoming the positioning bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

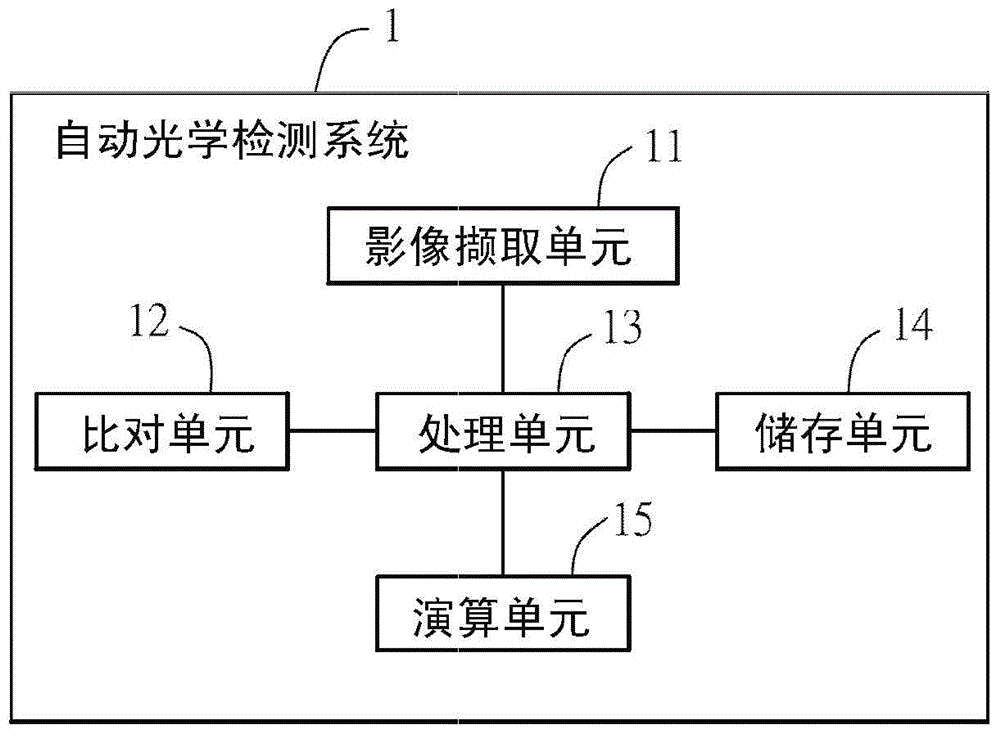

[0036] An image information detection method (hereinafter referred to as the detection method) according to a preferred embodiment of the present invention will be described below with reference to related drawings, which is applied to automatic optical detection, wherein the same components will be described with the same reference symbols.

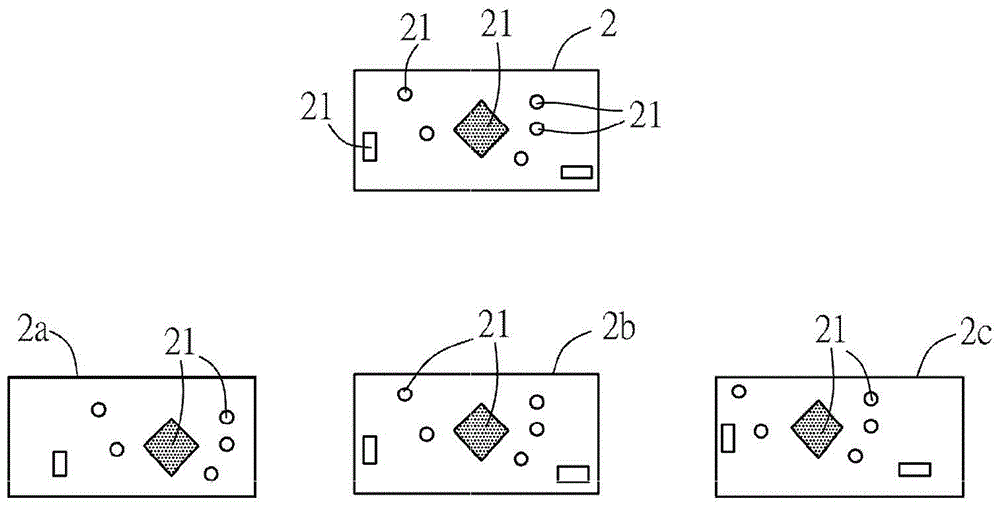

[0037] figure 1 It is a flow chart of the steps of an image information detection method in a preferred embodiment of the present invention, please refer to figure 1 As shown, the image information detection method of the present invention includes the following steps: selecting a matching data from a standard sample (S11); capturing a continuous image of a sample to be tested (S13); obtaining several frames of images to be tested from the continuous image (S15); selecting a characteristic data of each image to be tested (S17); and comparing the matching data and each characteristic data to obtain a matching rate (S19).

[0038] It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com