Power-driven and manual integrated specimen demolder

An integrated, demoulding device technology, applied in the preparation of test samples, etc., can solve the problems of oil leakage, poor operation continuity, small single stroke, etc., and achieve the effects of avoiding damage, convenient operation, and preventing overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the present invention.

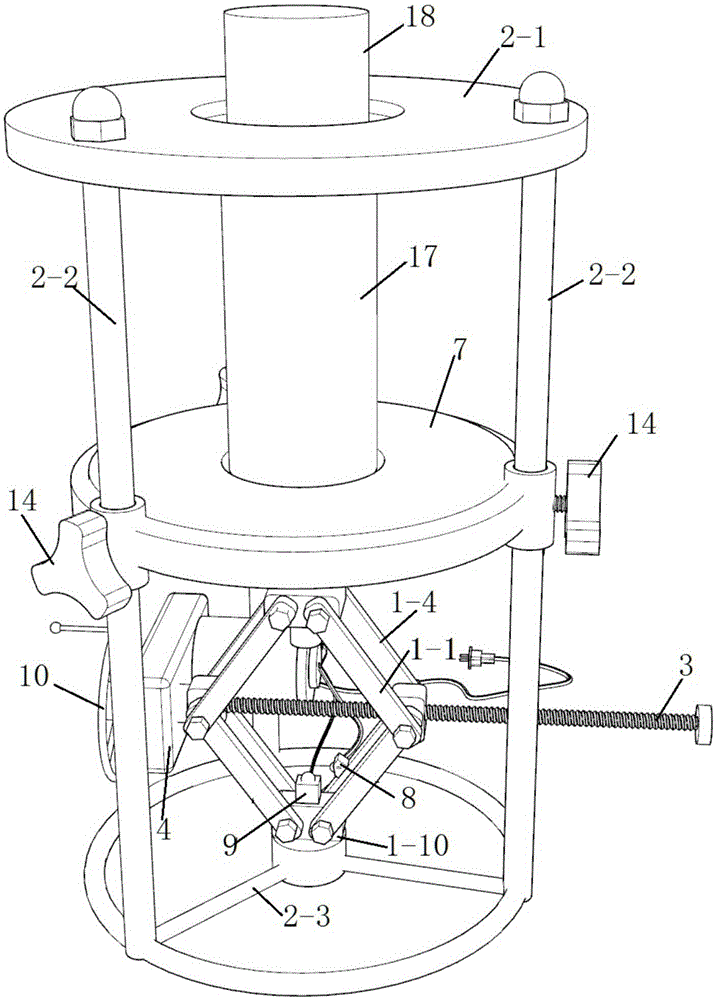

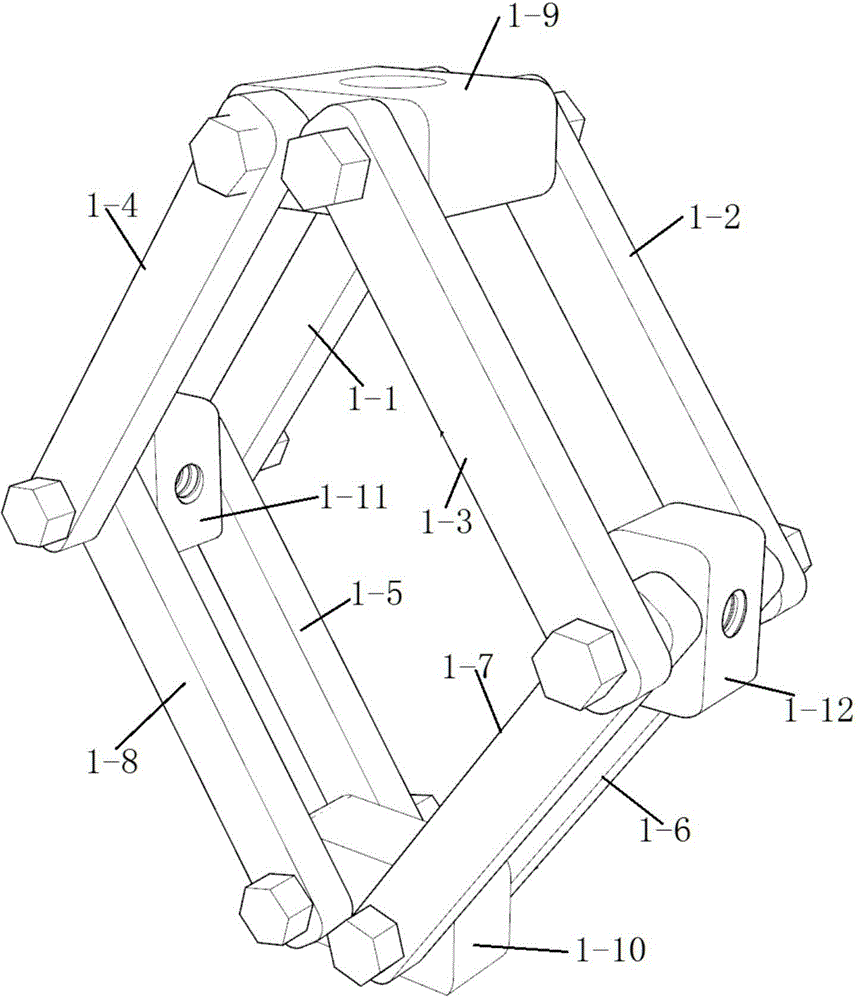

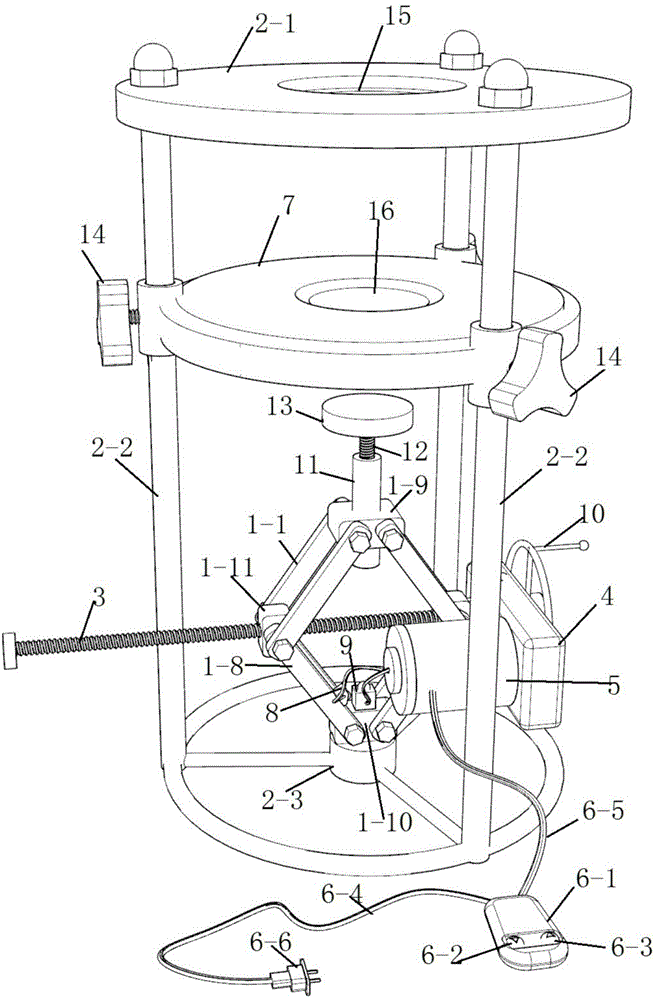

[0026] pass figure 1 , figure 2 , image 3 and Figure 4 It can be seen that the electric and manual integrated test piece stripper of the present invention includes a hinge lifting mechanism 1, a support frame 2, a drive screw 3, a reduction box 4, a motor 5, a control handle box 6, a lifting pallet 7, an upper limit Switch 8, lower limit switch 9, rotating hand wheel 10, internal thread pipe 11, lifting screw rod 12, sample pushing plate 13, fixed knob 14, upper demoulding hole 15, lower demoulding hole 16, and the support frame 2 includes a support Frame top plate 2-1, support column 2-2, support frame base 2-3, the hinge lifting mechanism 1 includes four lifting arms (1-1, 1-2, 1-3, 1-4), four Lower support arm (1-5, 1-6, 1-7 and 1-8), top pivot joint 1-9, bottom pivot joint 1-10, special-shaped pin nut 1-11, special-shaped pin nut 1 -12, the control handle box 6 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com