Method for constructing horizontal salt rock dissolving cavity reservoirs

A technology of salt rock dissolution cavity and construction method, which is applied to drilling equipment and methods, construction, earthwork drilling and mining, etc. It can solve problems such as difficult control, unfavorable regular shape storage storage construction, poor shape of dissolution cavity, etc., and achieve large storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

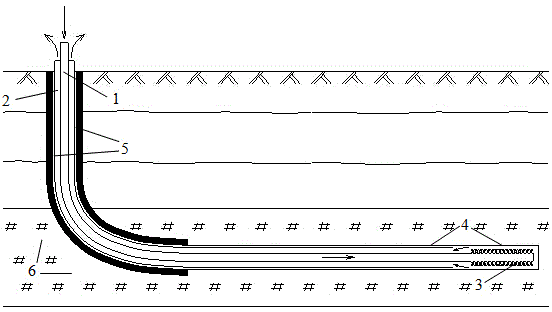

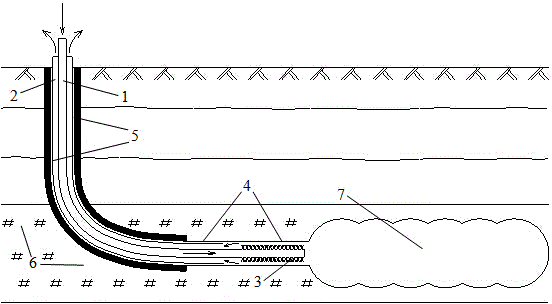

[0027] refer to figure 1 as shown,

[0028] A method for constructing a horizontal salt rock cavern storage, the steps of which are:

[0029] Ⅰ. Drill the vertical shaft and the deflected shaft from the ground to the middle position in the thickness direction of the target salt rock deposit, run the integral casing on the two sections of the vertical shaft and the deflected shaft, and carry out the full-length cement grouting cementing behind the wall;

[0030] Ⅱ. Drill a horizontal well 4 along the horizontal principal stress direction in the target salt rock deposit through the vertical shaft and the deflection well casing. Depending on the distribution of the ore deposit in the horizontal stress direction, the length of the horizontal well is 800m;

[0031] Ⅲ. Install the concentric production string system in vertical wells, deflected well casings and newly drilled horizontal wells. The string system is arranged along the entire length of the horizontal well. 1 The flowe...

Embodiment approach 2

[0039] Ⅱ. Drill a horizontal well 4 along the horizontal principal stress direction in the target salt rock deposit through the vertical shaft and the deflection shaft casing. The length of the horizontal well is 900m depending on the distribution of the ore deposit in the horizontal stress direction;

[0040] Ⅲ. In vertical wells, casings of deflected wells and newly drilled horizontal wells, install the concentric production string system, and the string system should be laid along the entire length of the horizontal well. The length of the side wall flower hole jet section 3 is 15m, inject fresh water into the salt rock deposit through the blind end of the side wall flower hole jet section 3 of the water injection pipe 1, dissolve the salt rock around the horizontal well 4, and the brine after dissolving the salt rock passes through the water outlet pipe 2 and the annulus between the water injection pipe 1 are discharged to the ground;

[0041] Ⅳ. In the pipe string system,...

Embodiment approach 3

[0046] Ⅱ. Drill a horizontal well 4 along the direction of the maximum horizontal principal stress in the target salt rock deposit through the casing of the vertical shaft and the deflection shaft. Depending on the distribution of the ore deposit in the direction of the horizontal stress, the length of the horizontal well is 1000m;

[0047] Ⅲ. In vertical wells, casings of deflected wells and newly drilled horizontal wells, install the concentric production string system, and the string system should be laid along the entire length of the horizontal well. The length of the side wall flower hole jet section 3 is 20m, inject fresh water into the salt rock deposit through the blind end of the side wall flower hole jet section 3 of the water injection pipe 1, dissolve the salt rock around the horizontal well 4, and the brine after dissolving the salt rock passes through the outlet pipe 2 and the annulus between the water injection pipe 1 are discharged to the ground;

[0048] Ⅳ. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com