Prefabrication method of concrete pile and its construction method

A concrete pile and concrete technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting pile bearing capacity, large settlement, broken piles, etc., shorten the construction period, increase the cross-sectional area of the pile, Effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

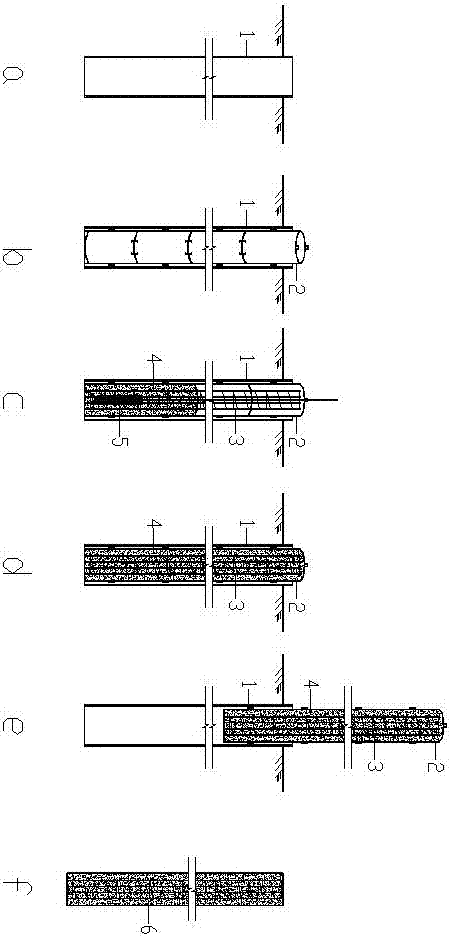

[0036] figure 1 It is the process diagram of the prefabrication method of the concrete pile of the present invention, as figure 1 As shown in middle a, the casing 1 is sunk vertically into the hole by power in the foundation until the predetermined depth; then, as figure 1 Shown in middle b, the sizing mold 2 that will assemble is sunk in the casing 1; Then, as figure 1 As shown in middle c, a reinforcement cage 3 is inserted into the inner cavity of the shaping mold 2, and then concrete 4 is poured into the inner cavity of the shaping mold 2, and a vibrator 5 is inserted into the inner cavity of the shaping mold 2 to vibrate the concrete dense; then, if figure 1 Shown in d, until the inner cavity of the shaping mold 2 is filled with concrete 4; then, as figure 1 As shown in middle e, the concrete 4 in the shaping mold 2 is maintained using the natural geothermal temperature of the soil, and after the concrete 4 in the shaping mold 2 has a certain strength, the shaping mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com