Oxidizing and granulating device for pigment carbon black and pigment carbon black prepared by same

A technology of pigment carbon black and granulation device, applied in the direction of fibrous fillers, etc., can solve the problems of aggravating the degree of dust pollution, difficult to paint, ink, powdery carbon black, etc. , The effect of easy dispersion processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

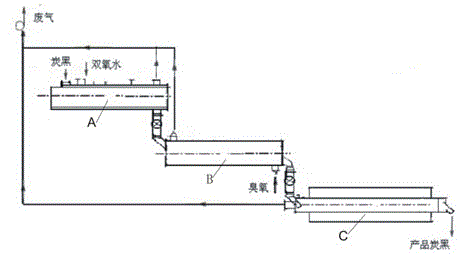

[0053] use as Figure 5 In the process flow shown, a certain powdery pigment carbon black is used as a raw material, and only a primary oxidation-granulator is used to oxidize and granulate the carbon black with hydrogen peroxide as an oxidant, and then dry to obtain the product.

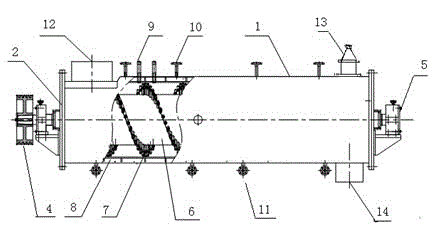

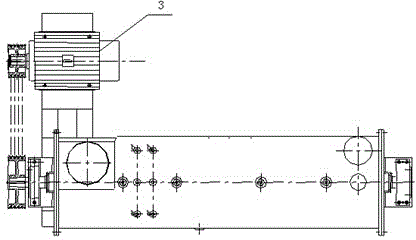

[0054] In the first-stage oxidation-granulator, the concentration of hydrogen peroxide is 20%, and the amount of hydrogen peroxide added is 1:1 of hydrogen peroxide to carbon black; the hydrogen peroxide is sprayed vertically by the water pump through 6 water nozzles distributed in front of the oxidation-granulator into the oxidation granulator; the injection pressure is 0.5 MPa; the rotating speed of the granulator is 460r / min; in order to facilitate granulation, steam is passed into the interlayer of the primary oxidation-granulator, and the pressure of the steam is 0.8MPa, so that The temperature inside the shell in the oxidation granulator reaches 60-70°C, the powdery carbon black enters the she...

Embodiment 2

[0063] use as Figure 6 The technological process shown, with the same powdery pigment carbon black of embodiment one as raw material, at first with hydrogen peroxide as oxidant, use primary oxidation-granulator to carry out oxidative treatment to carbon black, then use ozone as oxidant, use two The advanced oxidation-granulator is used to oxidize the carbon black and then dry it to obtain the product.

[0064] In the first-stage oxidation-granulator, the concentration of hydrogen peroxide is 20%, and the amount of hydrogen peroxide added is 1:1 of hydrogen peroxide to carbon black; the hydrogen peroxide is sprayed vertically by the water pump through 6 water nozzles distributed in front of the oxidation-granulator into the oxidation granulator; the injection pressure is 0.5 MPa; the rotating speed of the granulator is 460r / min; in order to facilitate granulation, steam is passed into the interlayer of the primary oxidation-granulator, and the pressure of the steam is 0.8MPa, ...

Embodiment 3

[0074] use as Figure 7 The process flow shown, using another granular commercial pigment carbon black as raw material, does not use the primary oxidation-granulator, does not use the rotary dryer, only uses the secondary oxidation-granulator to carry out the granular commercial carbon black post-oxidation treatment.

[0075] Secondary oxidation - the production capacity of the granulator is 800kg / h, the rotational speed of the granulator is 300 r / min, and a large-scale ozone generator is selected, the concentration of ozone produced by it is 20-30mg / l, and the gas supply volume is 105- 155Nm3 / h, ozone enters through the intake chamber, and exhaust gas is discharged from the exhaust gas exhaust chamber.

[0076] Table 3 Comparison table of the results of different oxidation treatments for another pigment carbon black

[0077]

[0078] From the comparison results in the table above, it can be seen that after the pigment carbon black is oxidized by ozone, the pH decreases, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com