Conducting photosensitive resin for 3D printing and preparation method thereof

A photosensitive resin and photosensitive technology, applied in the field of conductive photosensitive resin for 3D printing and its preparation, can solve the problems of poor mechanical properties and non-conductivity of photosensitive resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

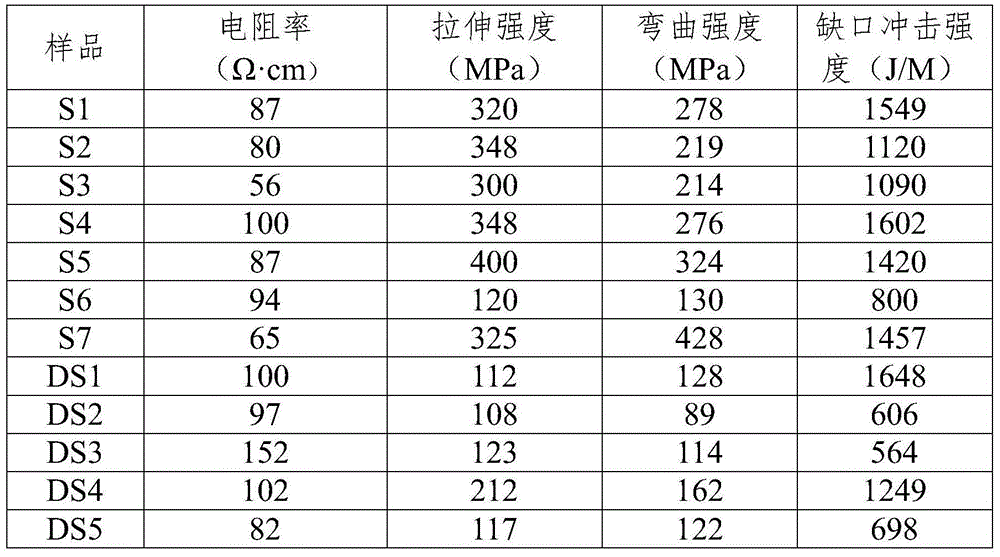

Examples

Embodiment 1

[0025] This example is used to illustrate the conductive photosensitive resin disclosed in the present invention and its preparation method.

[0026] Mix and stir 35 parts by weight of epoxy acrylate oligomer, 25 parts by weight of phenoxyethyl acrylate, and 15 parts by weight of trimethylolpropane triacrylate, then add 1 part by weight of benzoin dimethyl ether, 2 parts by weight Polyester-modified polydimethylsiloxane (BYK-307) and 17 parts by weight of carbon black (average particle size: 20nm) were heated and stirred in a water bath at 40°C to make them uniform.

[0027] Then vacuumize to remove air bubbles to obtain conductive photosensitive resin A1 with a viscosity of 300 mPa·s.

Embodiment 2

[0029] This example is used to illustrate the conductive photosensitive resin disclosed in the present invention and its preparation method.

[0030] Mix and stir 35 parts by weight of urethane acrylate oligomer, 30 parts by weight of phenoxyethyl acrylate, and 12 parts by weight of trimethylolpropane triacrylate, then add 1 part by weight of α-aminoketone photoinitiator, 2 parts by weight Parts of polyether-modified polydimethylsiloxane (BYK-310) and 20 parts by weight of silver powder (average particle size: 120nm), heated and stirred in a water bath at 50°C until uniform.

[0031]Then vacuumize to remove air bubbles to obtain conductive photosensitive resin A2 with a viscosity of 100 mPa·s.

Embodiment 3

[0033] This example is used to illustrate the conductive photosensitive resin disclosed in the present invention and its preparation method.

[0034] 30 parts by weight of epoxy acrylate oligomer, 15 parts by weight of phenoxyethyl acrylate, and 10 parts by weight of trimethylolpropane triacrylate are mixed and stirred, and then 1 part by weight of benzophenone photoinitiator, 4 parts by weight of polyether-modified polydimethylsiloxane (BYK-310) and 40 parts by weight of carbon black (with an average particle size of 20nm) were heated and stirred in a water bath at 30°C to make them uniform.

[0035] Then vacuumize to remove air bubbles to obtain conductive photosensitive resin A3 with a viscosity of 400 mPa·s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com