Sulfate-resistant concrete

A sulfate-resistant concrete technology, applied in the field of sulfate-resistant concrete and anti-corrosion concrete, can solve the problems of reducing the service life of concrete, easily destroying the concrete structure, and failing to achieve technical effects, etc., to prolong the service life, increase durability, and resist The attack effect of sulfate ion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

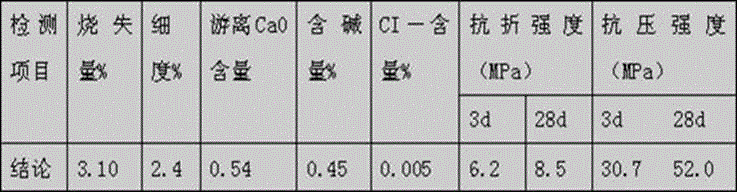

[0024] Embodiment 1: The concrete mix number of this embodiment is 01, and each proportioning raw material is composed of:

[0025] The total amount of cementitious material is 450kg / m3, the total amount of sand is 720kg / m3, and the total amount of gravel is 900kg / m3, of which: cement is 55% of the total weight of cementitious material, which is 247.5kg / m3; Mineral powder 95# is 25% of the total weight of the cementitious material, which is 112.5kg / m3; silica fume is 4% of the total weight of the cementitious material, which is 18kg / m3; fly ash is 18% of the total weight of the cementitious material, 81kg / m3; preservative is 0.8% of the total weight of the cementitious material, which is 3.6kg / m3; water reducing agent is 0.8% of the total weight of the cementitious material, which is 3.6kg / m3; 0.8% of the weight is 3.6kg / m3; the air-entraining agent is 0.015% of the total weight of the cementitious material, which is 0.0675kg / m3.

Embodiment 2

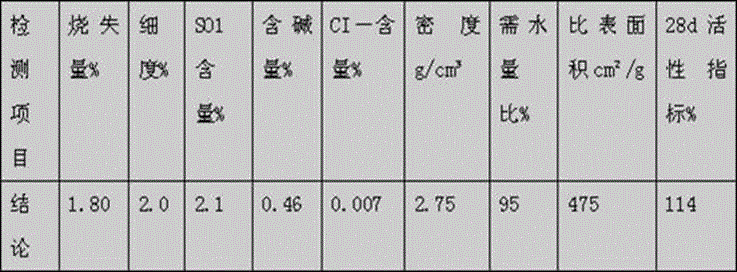

[0026] Embodiment 2: The concrete mix number of this embodiment is 02, and each proportioning raw material is composed of:

[0027] The total amount of cementitious material is 660kg / m3, the total amount of sand is 850kg / m3, and the total amount of gravel is 1150kg / m3, of which: cement is 60% of the total weight of cementitious material, which is 396kg / m3; granulated blast furnace ore Powder 95# is 15% of the total weight of the cementitious material, which is 99kg / m3; silica fume is 10% of the total weight of the cementitious material, which is 66kg / m3; fly ash is 15% of the total weight of the cementitious material, which is 99kg / m3; preservative is 1% of the total weight of the cemented material, 6.6kg / m3; water reducing agent is 0.5% of the total weight of the cemented material, 3.3kg / m3; 0.5%, which is 3.3kg / m3; the air-entraining agent is 0.01% of the total weight of the cementitious material, which is 0.066kg / m3.

Embodiment 3

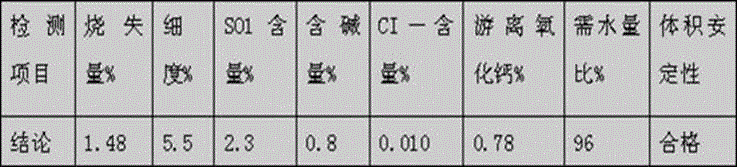

[0028] Embodiment 3: The concrete mix number of this embodiment is 03, and each proportioning raw material is composed of:

[0029] The total amount of cementitious material is 560kg / m3, the total amount of sand is 890kg / m3, and the total amount of gravel is 1180kg / m3, of which: cement is 67% of the total weight of cementitious material, which is 375.2kg / m3; Mineral powder 95# is 11% of the total weight of the cementitious material, which is 61.6kg / m3; silica fume is 6% of the total weight of the cementitious material, which is 33.6kg / m3; fly ash is 16% of the total weight of the cementitious material , is 89.6kg / m3; preservative is 1.5% of the total weight of the cemented material, which is 8.4kg / m3; water reducing agent is 1% of the total weight of the cemented material, which is 5.6kg / m3; rust inhibitor is gelled 1% of the total weight of the material is 5.6kg / m3; the air-entraining agent is 0.02% of the total weight of the cementitious material, which is 0.112kg / m3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com