Method and device applied to heating influent by virtue of efficient anaerobic reactor

An anaerobic reactor, high-efficiency technology, applied in chemical instruments and methods, anaerobic digestion treatment, energy wastewater treatment, etc., can solve the problems of polluted environment, unable to guarantee stable temperature of mesophilic anaerobic fermentation, energy reduction, etc., and achieve reduction The effects of environmental pollution, promotion of sustainable development, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

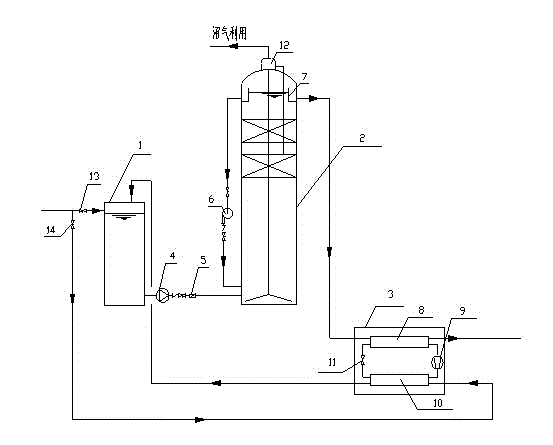

[0025] Embodiment: A method and device for heating the inlet water of a high-efficiency anaerobic reactor. The structure can refer to the accompanying drawings, and mainly includes a feed tank 1, a high-efficiency anaerobic reactor 2 and a heat pump unit 3. The heat pump unit 3 is composed of an evaporator 8 , a compressor 9 , a condenser 10 , an expansion valve 11 and gate valves 13 and 14 .

[0026] The feed tank 1, the high-efficiency anaerobic reactor 2 and the heat pump unit 3 are connected in sequence.

[0027] The heat pump unit 3 is composed of four devices: an evaporator 8 , a compressor 9 , a condenser 10 and an expansion valve 11 , which are connected to each other through refrigerant pipelines to form a closed circulation system.

[0028] The water inlet pipe of the feed tank 1 is connected to the water inlet of the condenser 10, the water outlet of the condenser 10 is connected to the feed tank 1 through a pipeline, and the water outlet system 7 of the high-effici...

experiment example

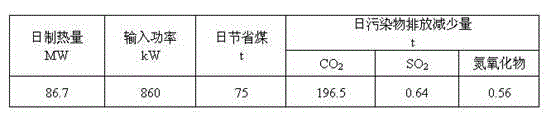

[0037] EXPERIMENTAL EXAMPLE An experiment was carried out using a method and device for heating the feed water of a high-efficiency anaerobic reactor described in the embodiment.

[0038] The amount of wastewater treated in this experiment is 5000m 3 / d, the inlet water temperature of the feed pool in cold regions is 15°C in winter, and the temperature of the heated anaerobic feed pool is 32°C (the heating season is calculated as 5 months), the temperature required for subsequent aerobic treatment at 23°C (the efficiency of the boiler is 20%, the efficiency of coal combustion is 70%, and the heat capacity of water is 4.2×103 J / (kg·℃), the calorific value of coal is 3.0×10 7 J / kg).

[0039] The design values of the heat pump unit are shown in the table below:

[0040]

[0041] The heating efficiency (COP) of the heat pump unit is taken as 4.2, and the experimental results obtained are shown in the following table:

[0042]

[0043] In the heating season, compared wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com