Method for preparing carbon microspheres through hydrothermal carbonization of biomass

A technology of hydrothermal carbonization and carbon microspheres, which is applied in the field of biomass-based hydrothermal carbonization to prepare carbon microspheres, which can solve the problems of high production cost of functional carbon microsphere materials, complicated raw material source process, and inability to realize green preparation, etc. problem, to achieve the effect of low price, wide source and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

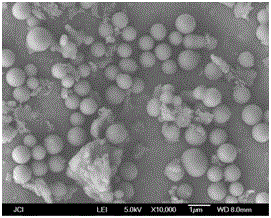

Embodiment 1

[0014] Add 1.0g of camellia seed hull powder to 30ml of deionized water, place it on a magnetic stirrer and mix for 6 hours, then transfer it to a 50ml stainless steel reactor, blow in nitrogen to deoxygenate, and put the reactor into a 230℃ blast drying oven Constant temperature reaction for 12h. The reaction kettle was naturally cooled to room temperature, the upper liquid was poured, the solid was taken out, and the washing liquid was ultrasonically cleaned with deionized water and absolute ethanol until the washing liquid was colorless, and then 30% ethanol-water solution was used under microwave-ultrasonic conditions at 60°C Extract 3 times, 30min each time. The mixture is vacuum filtered to obtain a solid, and then dried in a vacuum drying oven at 60° C. to obtain carbon microspheres. The average particle size of the obtained carbon microspheres is about 700 nm, and the yield is 32.5%. The specific surface area of the carbon microspheres measured by the BET method is 5...

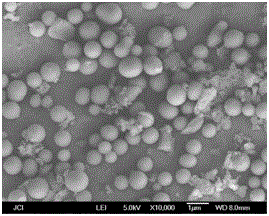

Embodiment 2

[0016] Add 2.0g of camellia seed husk powder to 60ml of deionized water, place it on a magnetic stirrer and mix for 6 hours, then transfer it to a 100ml stainless steel reactor, pour in nitrogen and deoxygenate, put the reactor into a 230℃ blast drying oven Constant temperature reaction for 12h. The reactor was naturally cooled to room temperature, the upper liquid was poured, and the solid was taken out. It was ultrasonically cleaned with deionized water and absolute ethanol until the washing solution was colorless, and then extracted with 30% ethanol-aqueous solution at 60°C by microwave-ultrasonic extraction 3 times for 30 minutes each time. The mixture is vacuum filtered to obtain a solid, and then dried in a vacuum drying oven at 60° C. to obtain carbon microspheres. The average particle size of the obtained carbon microspheres is about 700 nm, and the yield is 34.5%. The specific surface area of the carbon microspheres measured by the BET method is 55.3m. 2 / g, the tru...

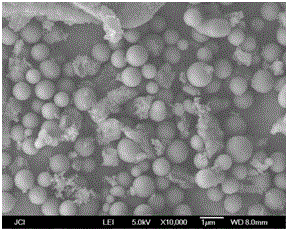

Embodiment 3

[0018] Add 1.0g of camellia seed hull powder to 30ml of deionized water, place it on a magnetic stirrer and mix for 6 hours, then transfer it to a 50ml stainless steel reactor, blow in nitrogen to deoxygenate, and put the reactor into a 230℃ blast drying oven Constant temperature reaction for 16h. The reaction kettle was naturally cooled to room temperature, and the upper liquid was poured. The solid was taken out, washed with deionized water and absolute ethanol in sequence until the washing liquid was colorless, and then extracted with 30% ethanol-water solution at 60°C by microwave-ultrasonic extraction 3 times, each for 30 min. The mixture is vacuum filtered to obtain a solid, and then dried in a vacuum drying oven at 60° C. to obtain carbon microspheres. The average particle size of the obtained carbon microspheres is about 500nm, and the yield is 34.3%. The specific surface area of the carbon microspheres measured by the BET method is 56.1m. 2 / g, the true density is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com