Energy-saving control device for AC electric welding machine

A technology of energy-saving control and alternating current, applied in auxiliary devices, arc welding equipment, manufacturing tools, etc., can solve problems such as difficult to achieve, difficult to popularize, and inflexible to use, so as to improve the average power factor, facilitate production and popularization, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

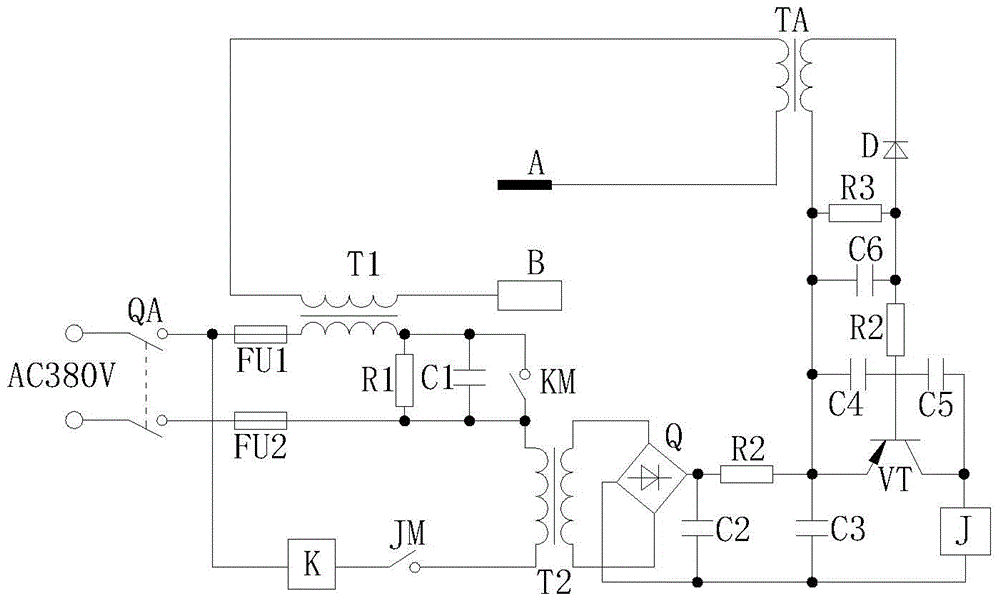

[0010] like figure 1 Shown: the present invention includes a power switch QA, a first fuse resistor FU1, a second fuse resistor FU2, a current transformer TA, an AC contactor K, a welding transformer T1, a transformer T2, a first capacitor C1, and a second capacitor C2 , third capacitor C3, fourth capacitor C4, fifth capacitor C5, sixth capacitor C6, first resistor R1, second resistor R2, third resistor R3, rectifier Q, transistor VT, diode D and relay J, welding transformer The first end of the primary coil of T1 is connected to the live wire of the AC power supply, and the second end of the primary coil of the welding transformer T1 is simultaneously connected to the first end of the first resistor R1, the first end of the first capacitor C1 and the normally open contact switch of the AC contactor The first end of KM is connected, and the second end of the first resistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com