Method for reducing no-load loss of inverter with two-stage structure

A no-load loss and inverter technology, which is applied in the direction of instruments, electric variable adjustment, output power conversion devices, etc., can solve the problems of low device working efficiency and device failure, achieve high working efficiency and reduce no-load loss , The control method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

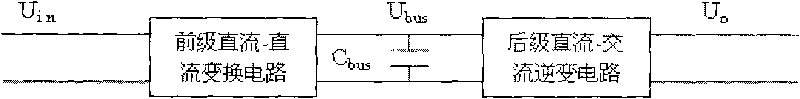

[0040] An embodiment of the present invention is a vehicle-mounted inverter that adopts a method for reducing no-load loss. circuit such as Figure 5 As shown, it mainly consists of the following parts: 12VDC lead-acid battery pack (1); push-pull DC-DC conversion circuit (2); full-bridge DC-AC inverter circuit (3); isolated drive circuit A (4) ; Isolation drive circuit B (5); TMS320C2812 processor (6); Detection and conversion circuit (7).

[0041] 12VDC lead-acid battery pack (1) voltage U in The allowable variation range is 10VDC~14.7VDC.

[0042] Push-pull DC-DC conversion circuit (2) power tube Q 1 and Q 2 Five IRF3205s are used in parallel, the ratio of the primary and secondary sides of the transformer is 2:72, and the diode D 1 ~D 4 RHRP8120 is used. Inductance L s is 1mH. The circuit switching frequency is 30kHz. Intermediate bus capacitance C bus 1000uF / 500VDC, intermediate DC bus voltage U bus The allowable change range is 340VDC ~ 480VDC.

[0043] Power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com