Amorphous alloy delta transformer core

A technology of transformer iron core and amorphous alloy, which is applied in the field of transformer iron core, can solve the problems of increased no-load loss of iron core, consumption of copper material, low-frequency vibration at joints, etc., and achieves small no-load loss, convenient assembly and saving The effect of copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

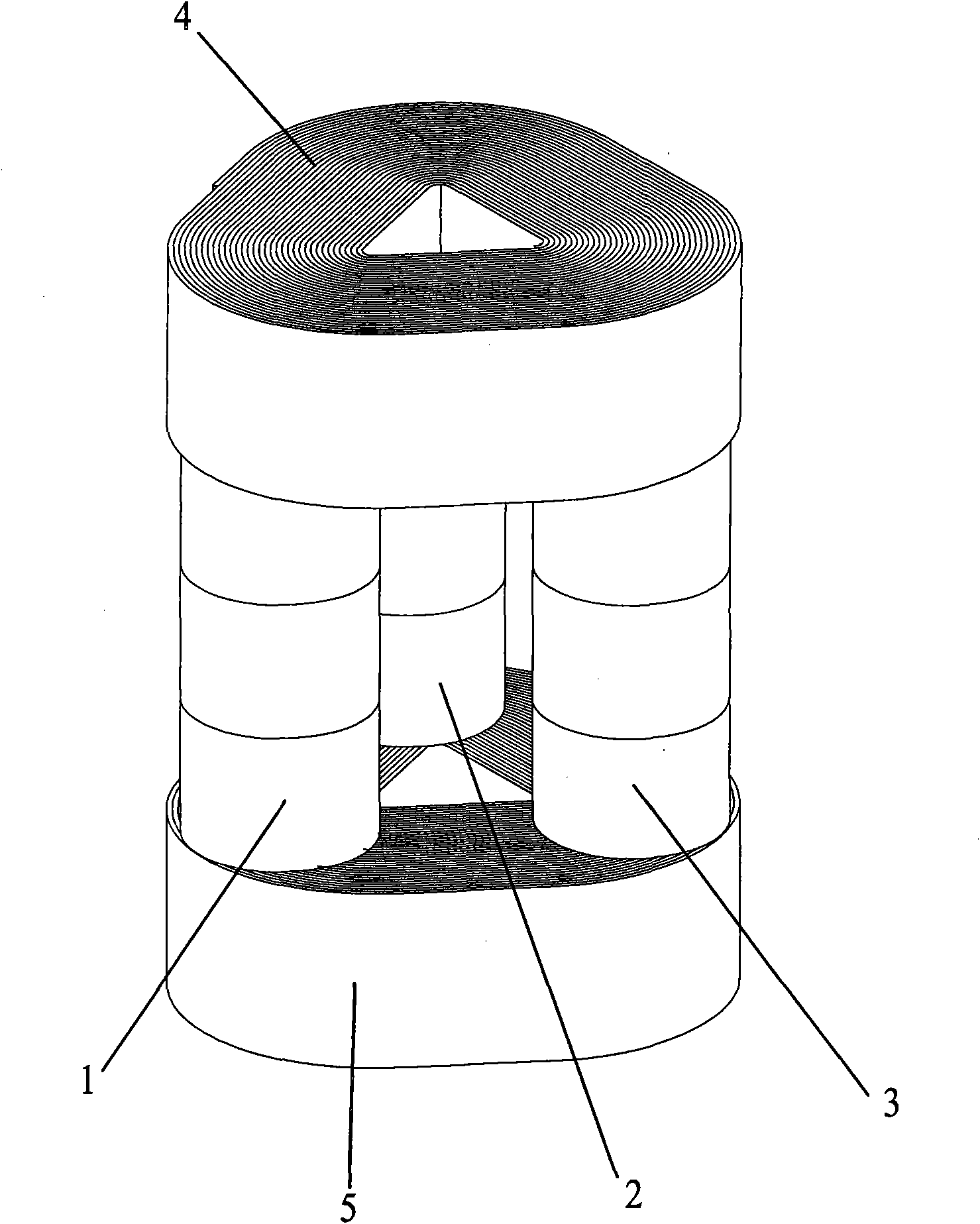

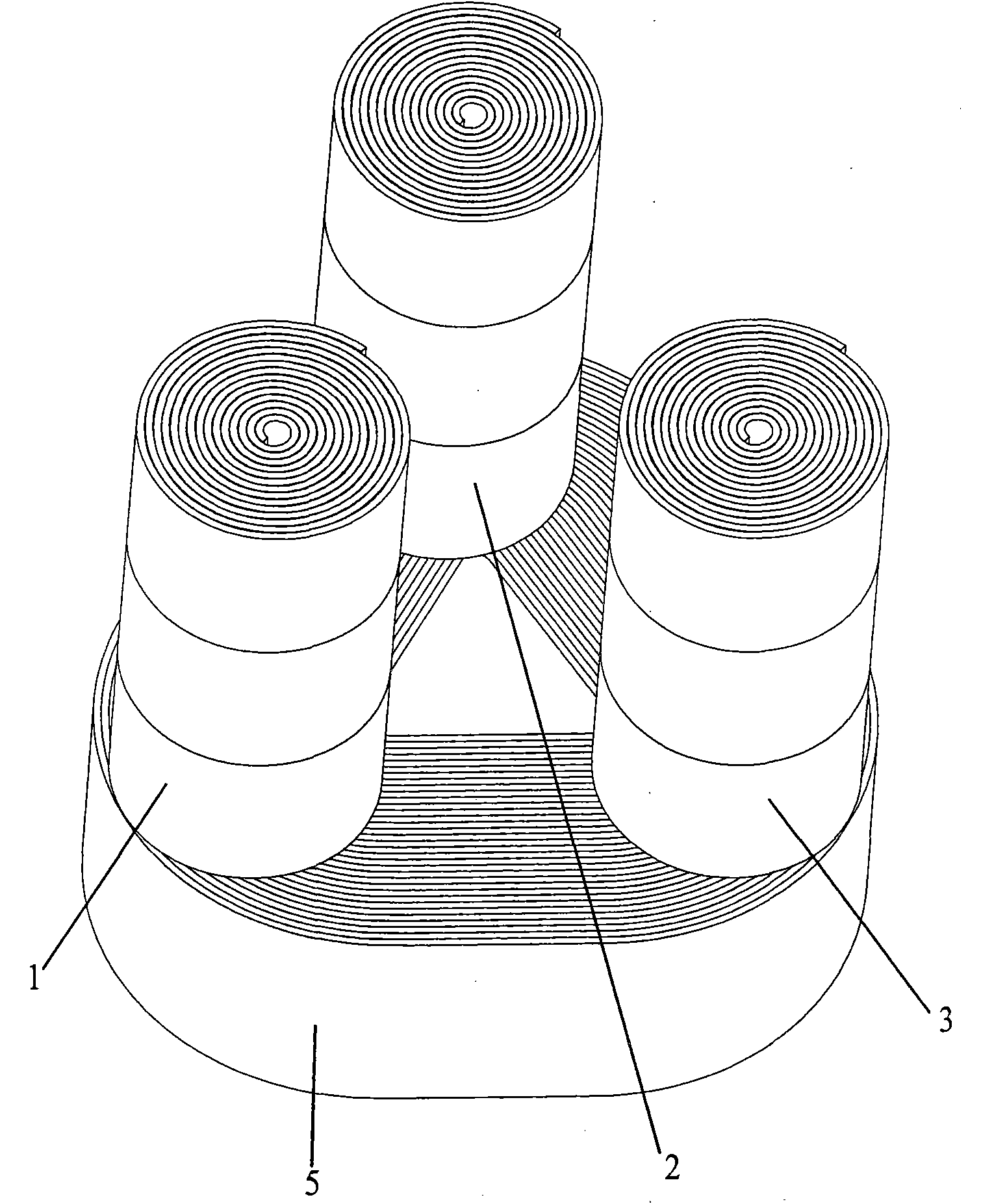

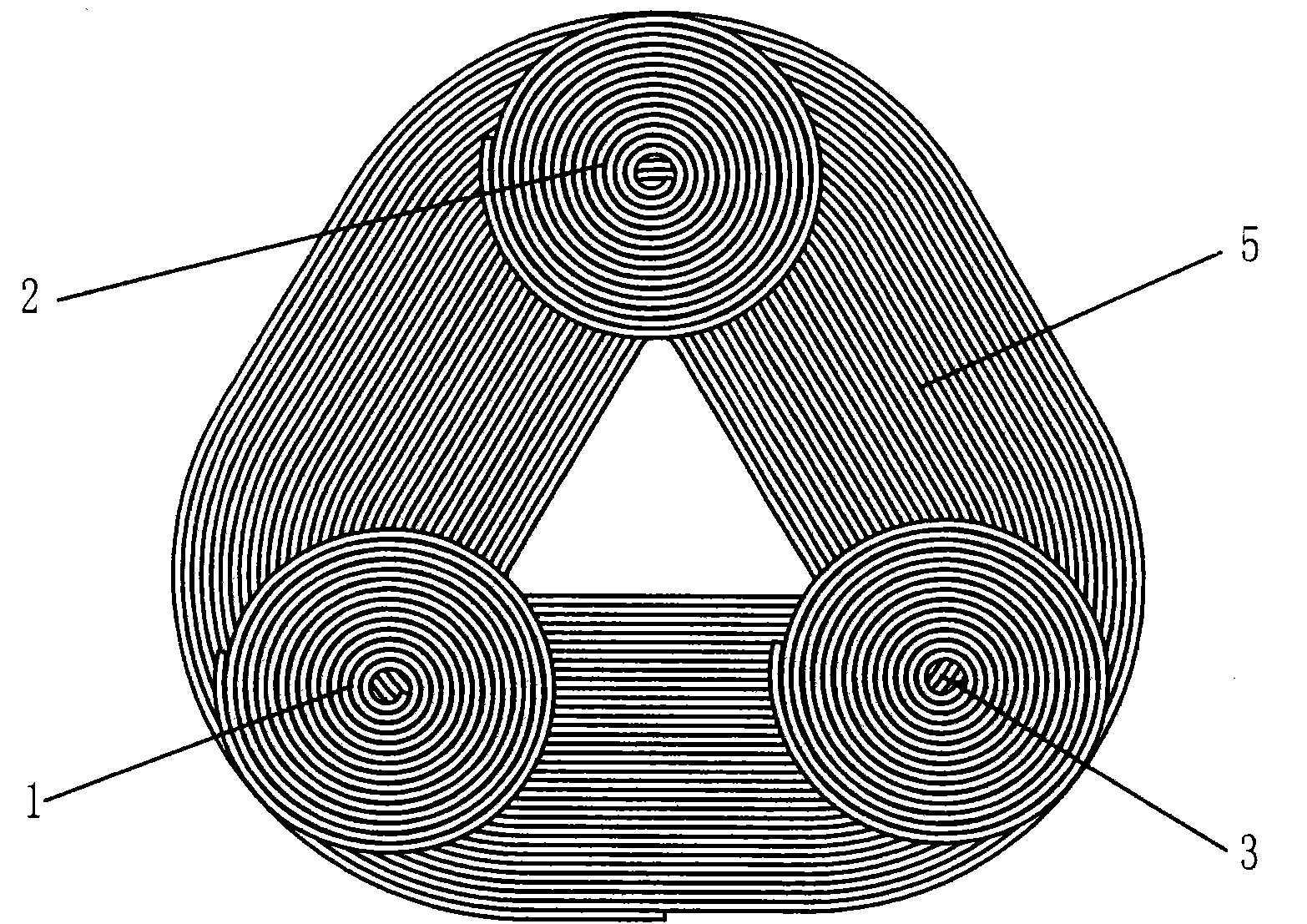

[0009] As shown in the figure: the amorphous alloy triangular transformer core includes an iron core column, an upper iron yoke 4 located at the upper end of the iron core column and a lower iron yoke 5 located at the lower end of the iron core column, and the iron core column is made of the same It is composed of independent first iron core column 1, second iron core column 2 and third iron core column 3. Each iron core column has the same height and is formed by winding two or more amorphous alloy strips. Composed of cylindrical butt joints, each iron core column has a circular through hole in the center; the upper iron yoke 4 and the lower iron yoke 5 are the same, and are respectively wound by continuous amorphous alloy strips of equal width A triangular frame, the central holes of the upper iron yoke 4 and the lower iron yoke 5 are equilateral triangles, and the outer edges of the upper iron yoke 4 and the lower iron yoke 5 are equilateral triangles with rounded corners; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com