Subsoiling machine drill structure

A technology of loose cultivators and drill bits, which is applied in the fields of tillage machines, agricultural machinery and tools, etc. It can solve problems such as complicated procedures, low efficiency, and serious hardening, and achieve the effect of high linear speed of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

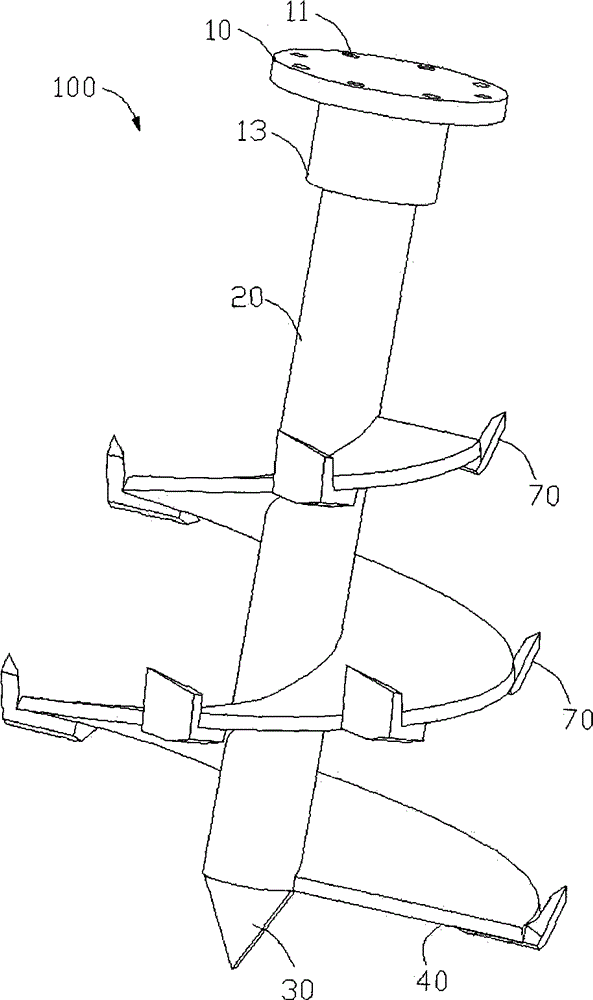

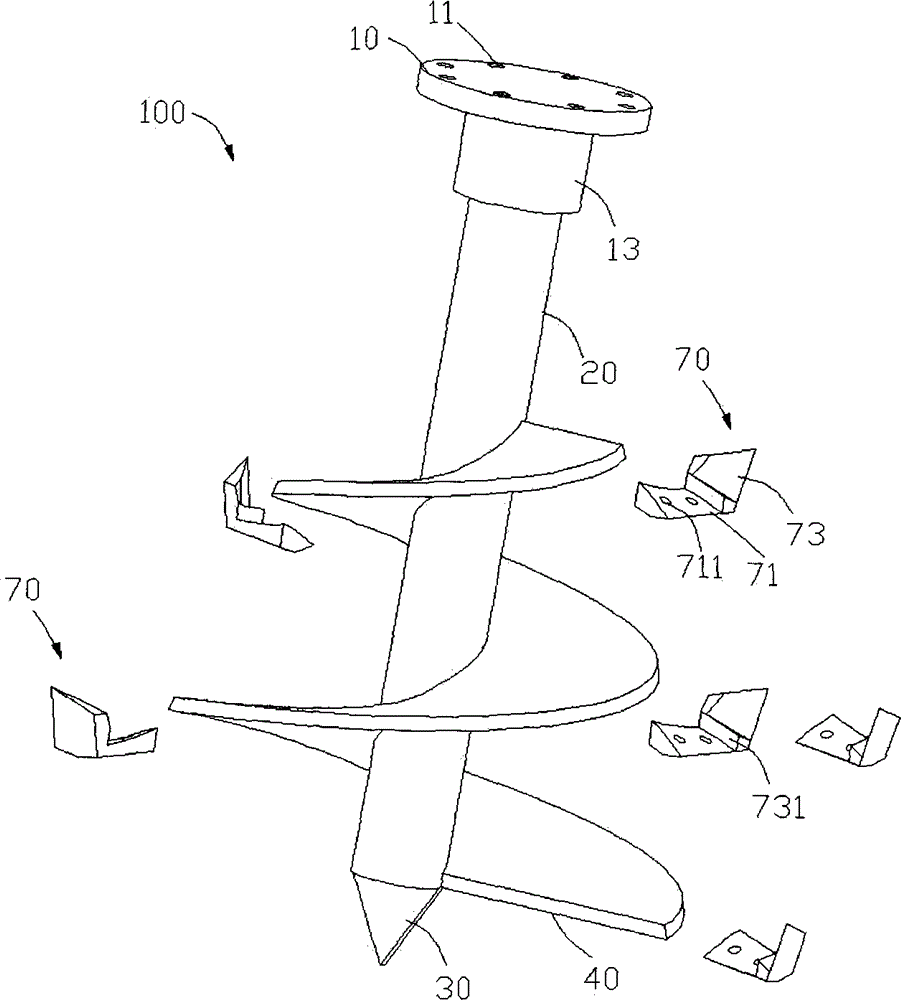

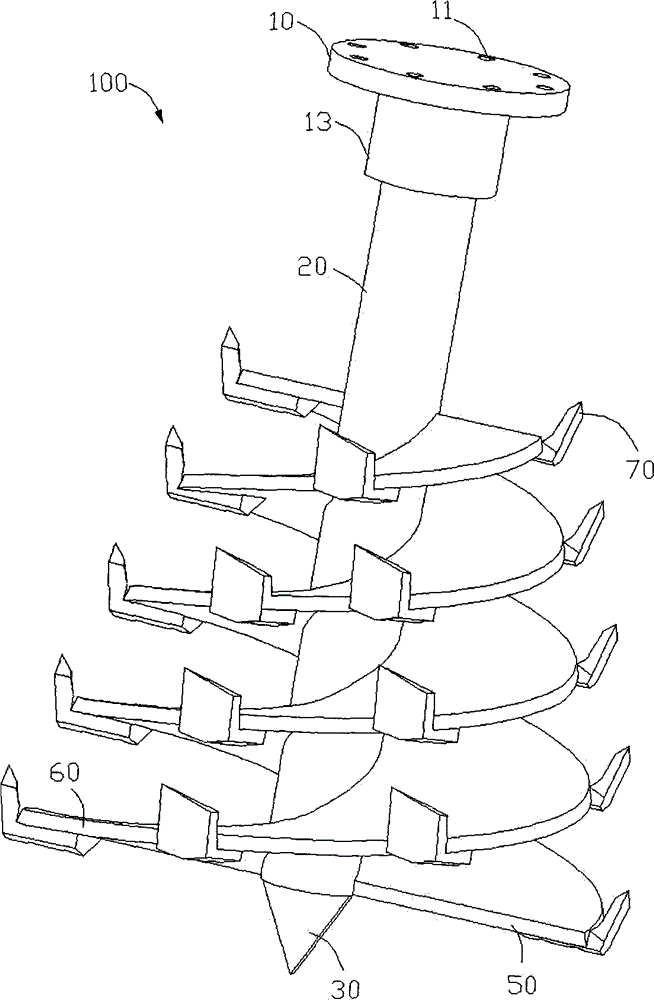

[0022] see figure 1 or image 3 , a tiller drill bit structure 100 includes a connecting flange 10 , a drill rod 20 , a drill bit body 30 , at least one helical blade and a plurality of drill bits 70 . The tiller drill bit structure 100 is used to perform powder ridges on land planted with various crops, such as rice, corn, sugar cane, soybeans, etc. In the first embodiment of the present invention, the tiller bit structure 100 includes a helical blade 40 . In the second embodiment of the present invention, the tiller bit structure 100 includes a left helical blade 50 and a right helical blade 60 .

[0023] The connecting flange 10 defines a plurality of screw holes 11 and extends downwards with a neck 13 for connecting the drill rod 20 . In the embodiment of the present invention, the outer diameter of the neck portion 13 is smaller than the outer diameter of the connecting flange 10 . The connecting flange 10 is locked into the screw hole 11 and the output shaft (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com