Etching method and semiconductor device

A semiconductor and etching technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems affecting the performance of semiconductor devices, production decline, etc., to avoid production decline, avoid residual problems, and reduce the effect of probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

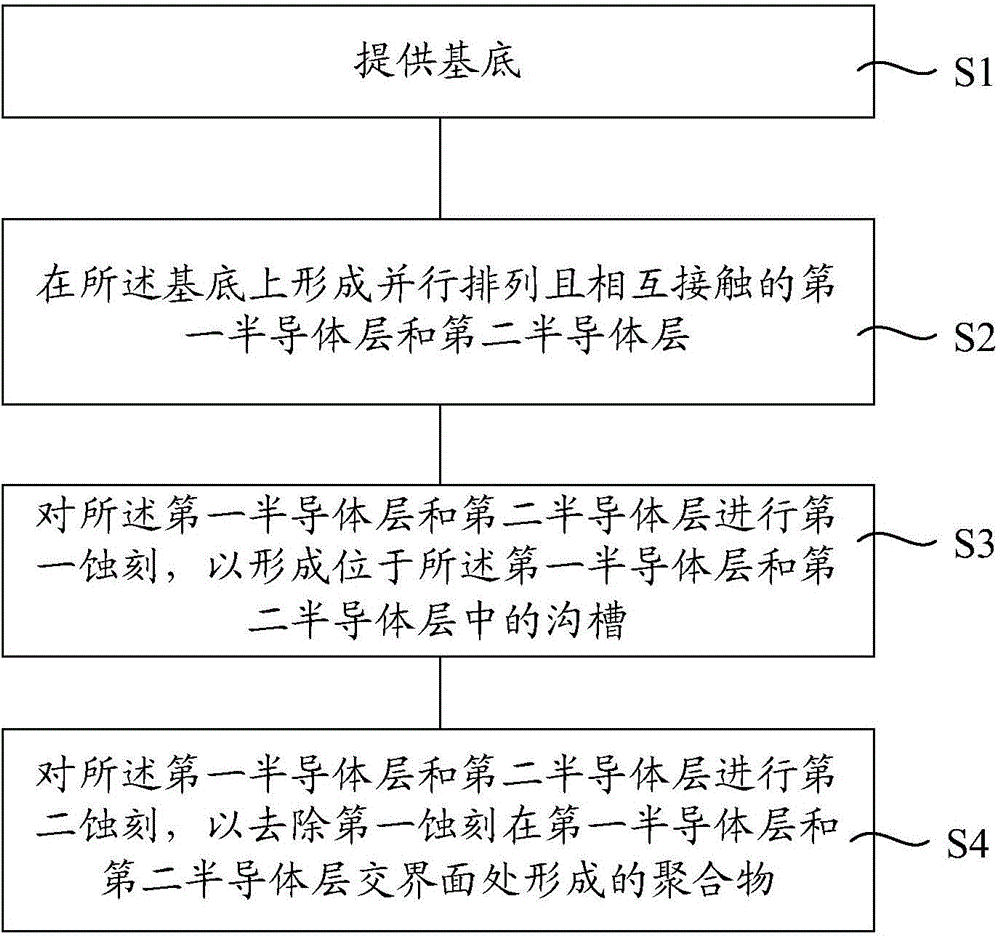

[0030] In the prior art, when the semiconductor layer stack structure is etched, residues are easily generated, and the residues may affect the performance of the semiconductor device, and even lead to a decrease in the yield of the semiconductor device.

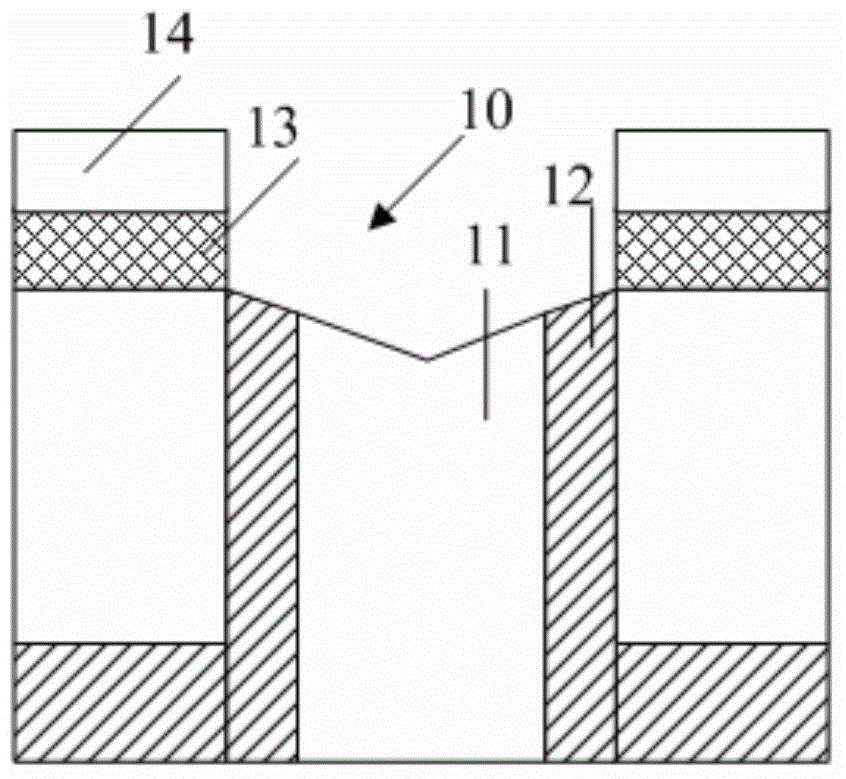

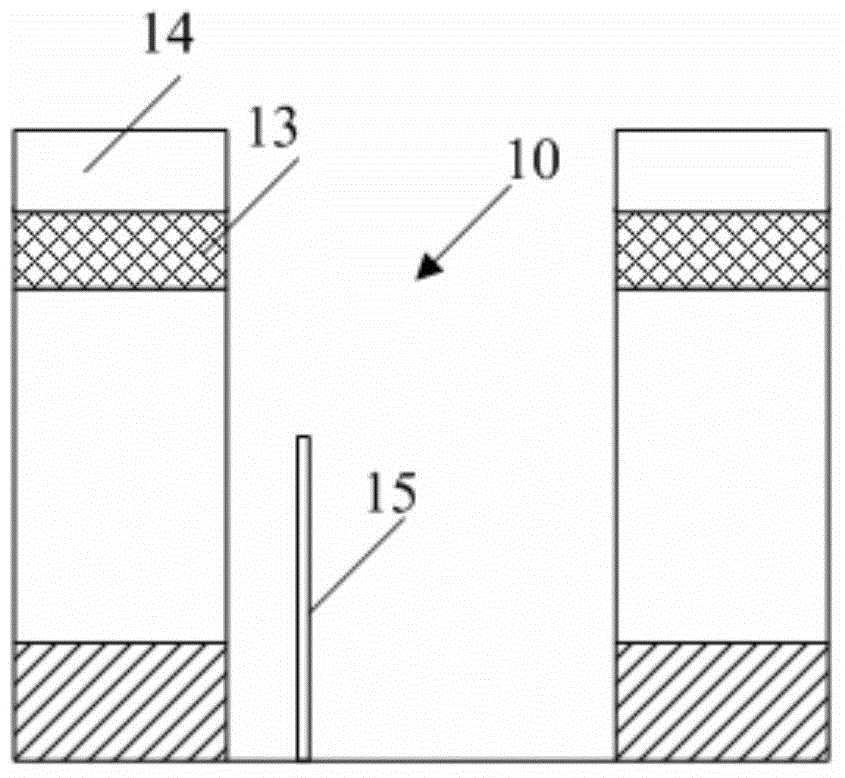

[0031] In order to reduce the residues, the materials and causes of the residues are analyzed. Combine below figure 2 , combined with the figure 2 Analysis of semiconductor devices.

[0032] During the process of etching to form the trench 10 , the etching rates of the first semiconductor layer and the second semiconductor layer are different, and an etching gas is used in the etching to form a polymer on the sidewall of the semiconductor layer with a slower etching rate.

[0033] The polymer is equivalent to a small mask. During the etching process, the polymer is used as a mask for etching. The semiconductor layer located under the polymer is not easily removed and remains at the bottom of the trench 10 to form a resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com