A collimator and in-line polarizer including the collimator

A technology of collimator and polarization-maintaining fiber, which is applied in the field of online polarizer, can solve the problem that the length cannot be made too short, achieve the effect of small size, reduce the reflection and loss of the optical path, and improve the performance of high power resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] The specific realization of the present invention is described in detail below in conjunction with specific embodiment:

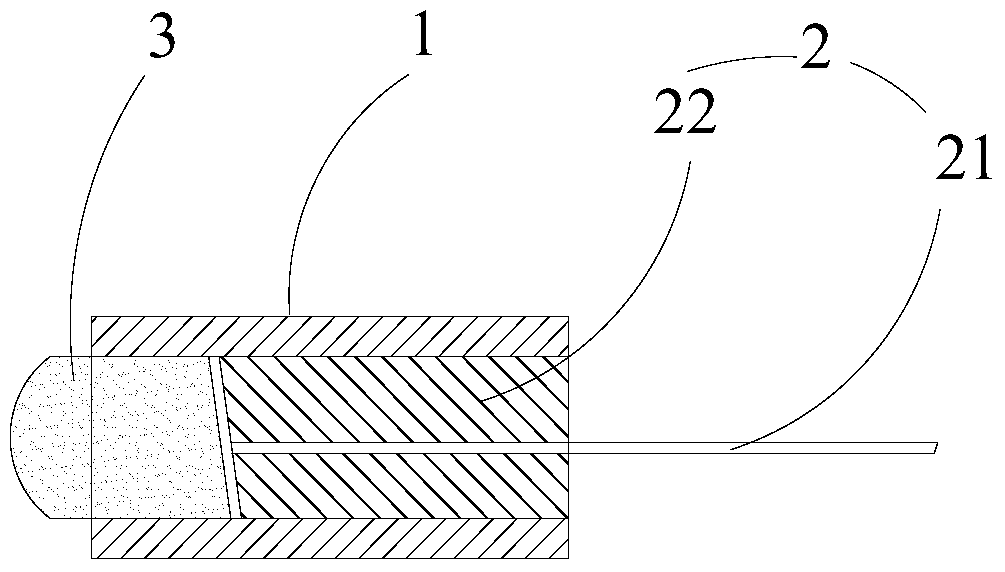

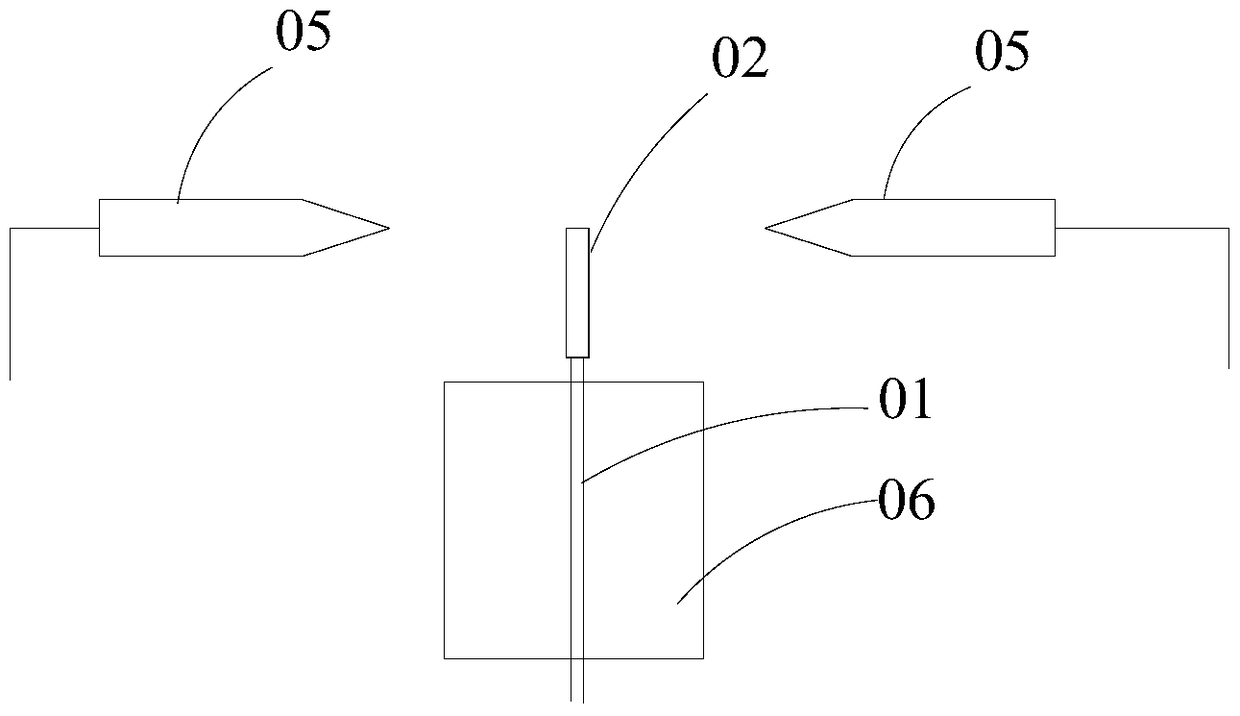

[0017] Please refer to figure 2 , the embodiment of the present invention provides a collimator, which is used in an online polarizer, which includes a section of polarization maintaining fiber 01, and a multimode fiber 02 or a coreless fiber fused to one end of the polarization maintaining fiber 01, the multimode fiber 02 or the end of the coreless fiber is melted into a spherical microlens 03, and the central axis of the spherical microlens 03 is collinear with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com