Integral ram five-axis assembly

A technology of shaft assembly and ram, which is used in driving devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low cutting force, low power and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

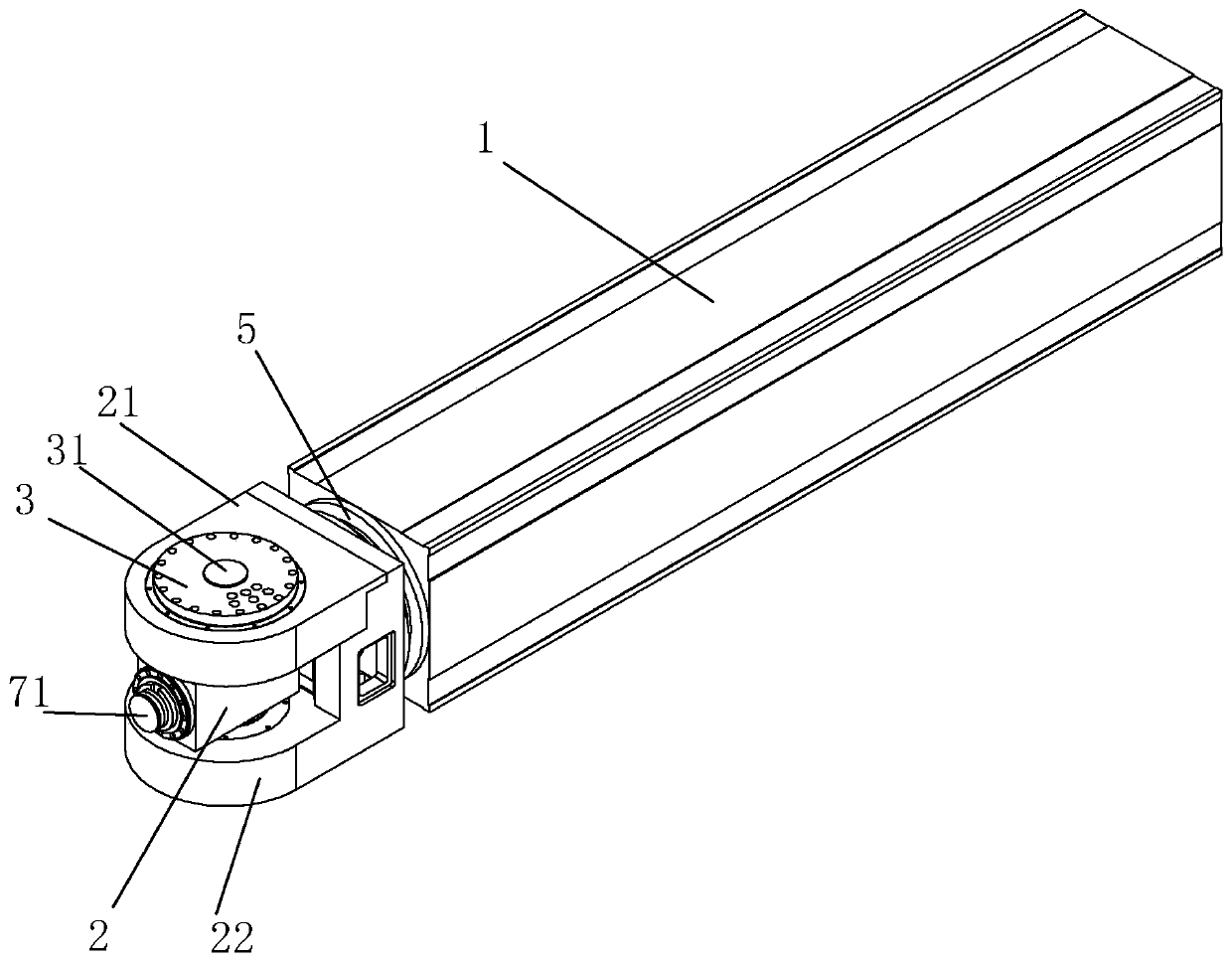

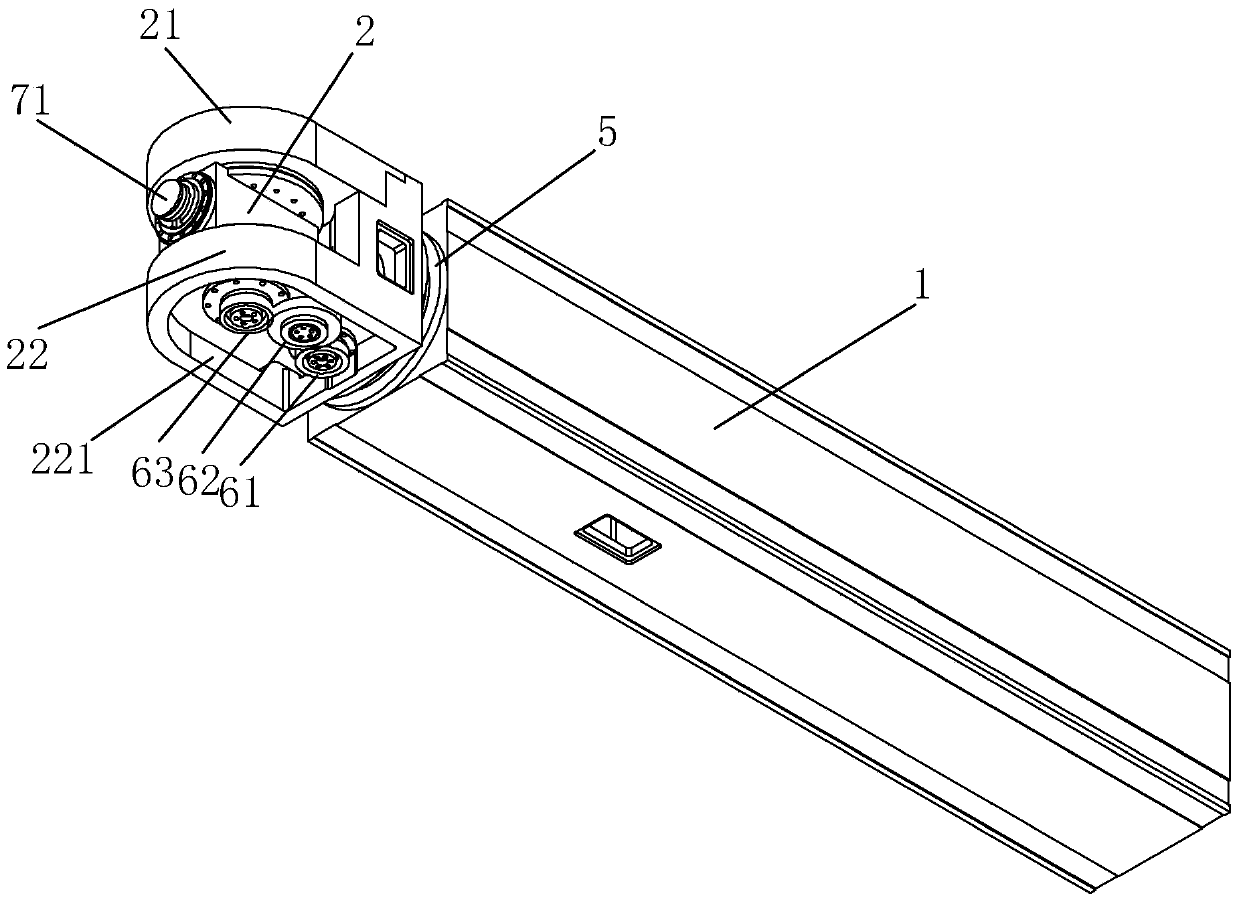

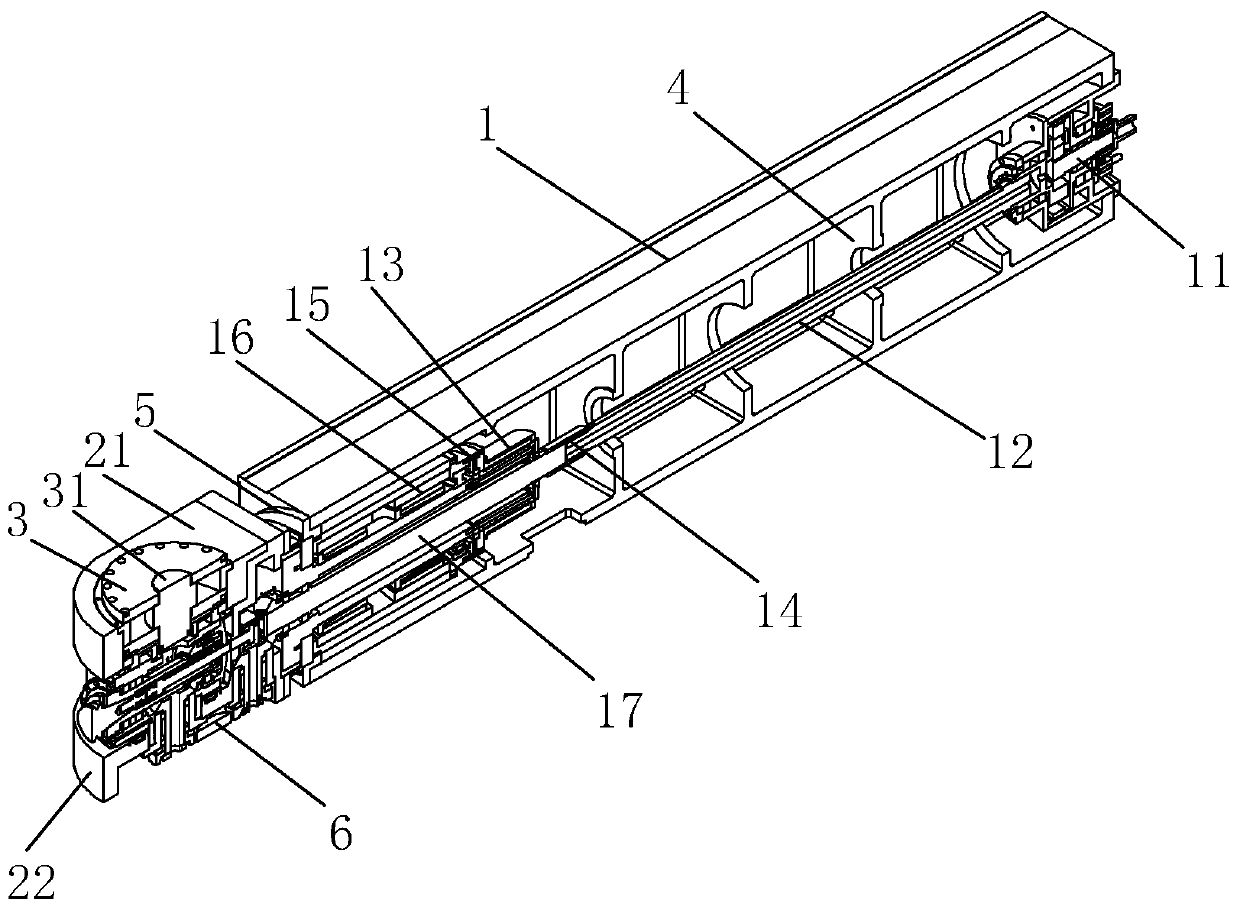

[0024] Embodiment: A five-axis assembly of an integral ram, including a ram 1 and a headstock 2, the ram 1 and the headstock 2 are connected by a rotary shaft 5, and the inside of the ram 1 moves from the end far away from the headstock 2 to the close One end of the headstock 2 is provided with a speed reducer 11 and a braking device 15 in turn, and a worm gear shaft 17 is also provided in the ram 1, and the worm gear shaft 17 is connected with the output shaft 12 of the accelerator through a spline, and a The connecting sleeve 14, and an oil separator 13 is also provided on the worm gear shaft 17. On the side of the oil separator 13 near the headstock 2 is a brake device 15, and on the side of the brake device 15 near the headstock 2 are two torque motors 16 or hydraulic swing cylinders. These two torque motors 16 are for the worm gear shaft. The swing of 17 produces effect, also can replace with hydraulic swing cylinder, so that the swing of worm gear shaft 17 is more stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com