Method for testing acetic acid distillation tower top composition by using gas chromatographic method

A gas chromatography and gas chromatography technology, applied in the field of gas chromatography to determine the composition of acetic acid distillation tower overhead, can solve the problems of time-consuming, labor-intensive and accuracy, and achieve the effects of saving time, improving accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In order to overcome the problem in the prior art that three different methods are required to measure the component content of the overhead sample of acetic acid distillation, which is time-consuming and laborious and has low accuracy, this embodiment provides a gas chromatographic method The method for measuring the composition of acetic acid rectification overhead product may further comprise the steps:

[0025] 1) Preparation of detection instruments and reagents; prepare one gas chromatograph, one volumetric flask, one electronic balance, a certain amount of water, acetic acid reagent, sec-butyl acetate reagent, standard substance and sample solution of acetic acid distillation overhead , the standard substance is selected according to the type of detector in the selected gas chromatograph, general thermal conductivity detector (TCD detector) selects benzene for use, and hydrogen flame detector selects n-heptane for use;

[0026] 2) configure the standard solution;...

Embodiment 2

[0031] The present embodiment provides a method for measuring the composition of acetic acid rectification overhead by gas chromatography, comprising the following steps:

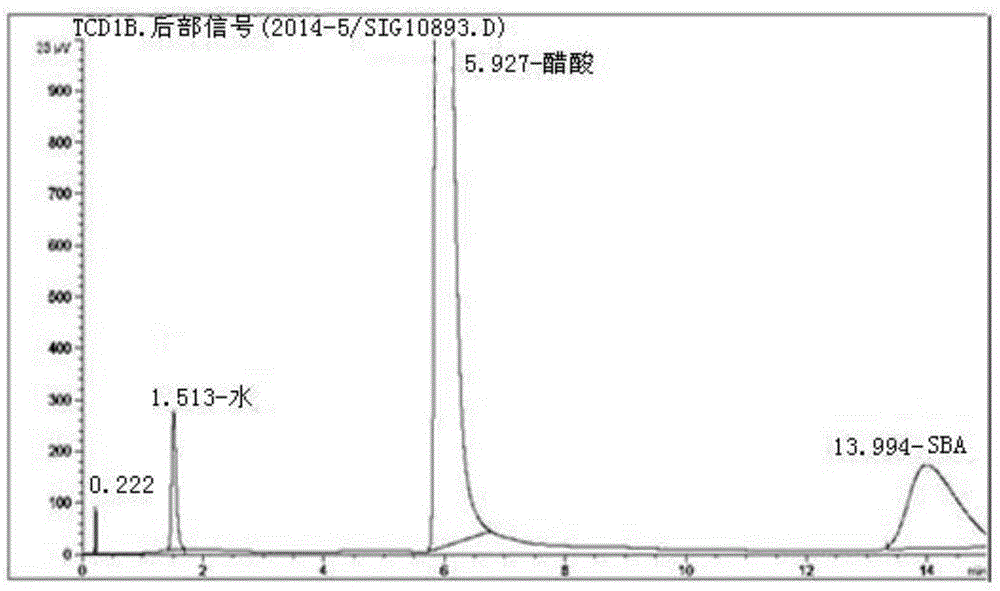

[0032] 1) Preparation of detection instruments and reagents; prepare one Agilent 7820A gas chromatograph, one 100ml volumetric flask, one electronic balance, a certain amount of water, acetic acid reagent, sec-butyl acetate reagent, standard substance and the top of the acetic acid distillation tower substance sample solution, the water used is high-purity water (purity 99.99%, the content of impurities is less than 0.1mg / L, and the salt content is below 0.3mg / L), the purity of the acetic acid reagent used is chromatographically pure grade, and the sec-butyl acetate used The purity of the reagent is chromatographically pure grade, the standard substance used is benzene, and the purity of the standard substance used is chromatographically pure grade. The detector in the gas chromatograph adopts a TCD detecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com