Waterproof and drainage structure of vertical shaft in underground workhouse and construction method for waterproof and drainage structure

A technology for underground powerhouses and construction methods, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of blind ditch being easily blocked, failure of drainage, unsatisfactory drainage effect, high construction cost, etc., and achieve waterproof and anti-seepage effects Good, strong water seepage effect, convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

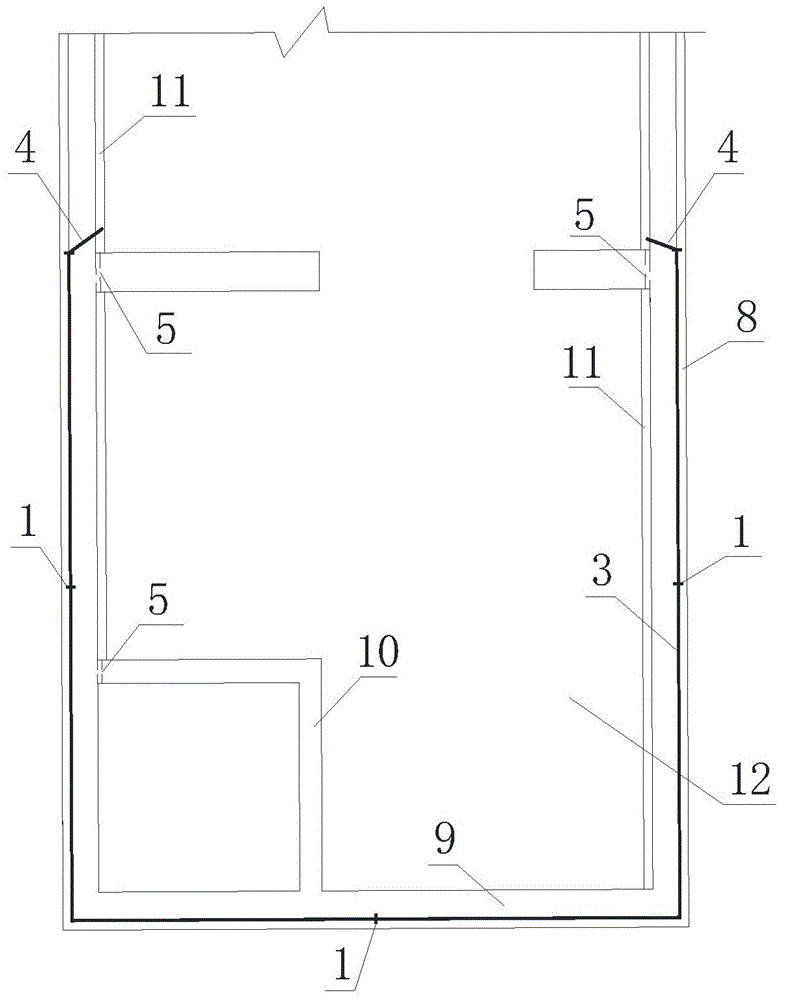

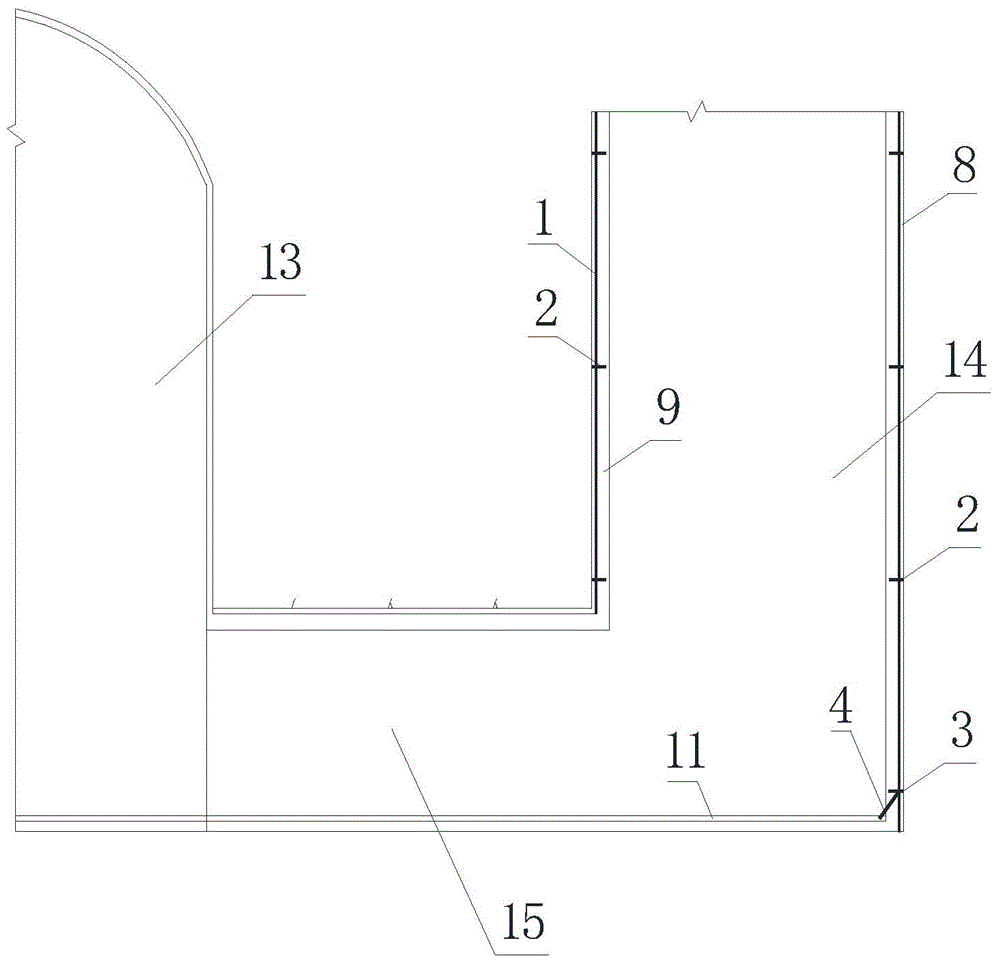

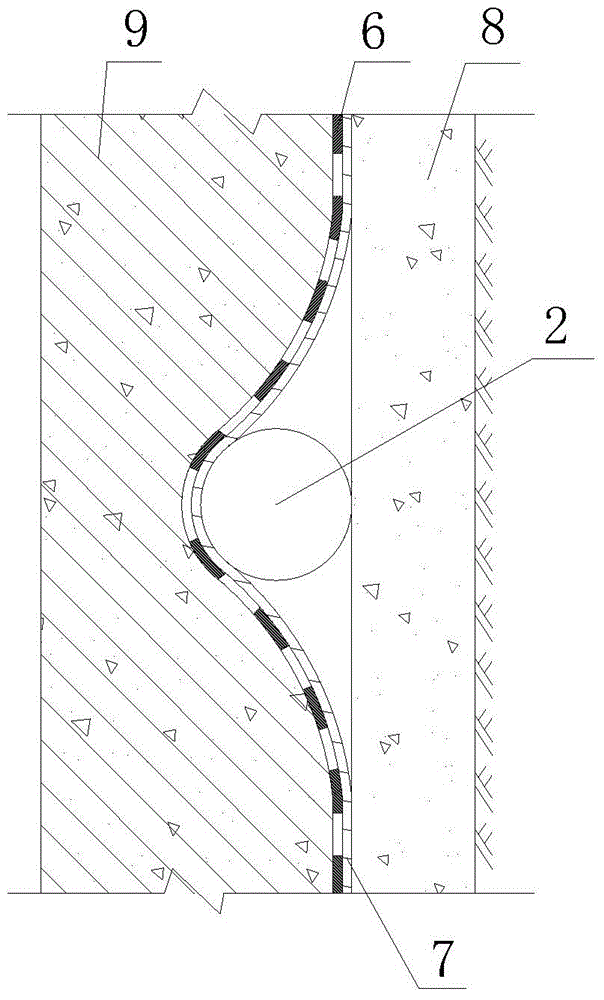

[0030] Such as Figure 1 to Figure 4 As shown, a vertical shaft waterproof and drainage structure of an underground factory building according to the present invention includes a main variable hole 13 connected to an outgoing line corridor 15 and an outgoing line shaft 14. The outlet shaft shaft consists of the first-stage shotcrete 8 and the second-stage lining concrete 9. A waterproof and drainage layer is arranged between the first-stage shotcrete 8 and the second-stage lining concrete 9. The waterproof and drainage The layer includes permeable pipes, a buffer layer 7 and a waterproof board 6 arranged in the shotcrete 8 of the first stage, and a concrete elevator shaft shaft 10 is also arranged in the vertical shaft of the underground workshop. In this technical scheme, after the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com