Method for reinforcing midspan of ordinary three-span steel continuous beam bridge

A common steel bar and steel bar technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of lagging stress and strain, failing to reach the design value of tensile strength, and limited improvement of the flexural bearing capacity of the main girder, so as to improve the flexural bearing capacity effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

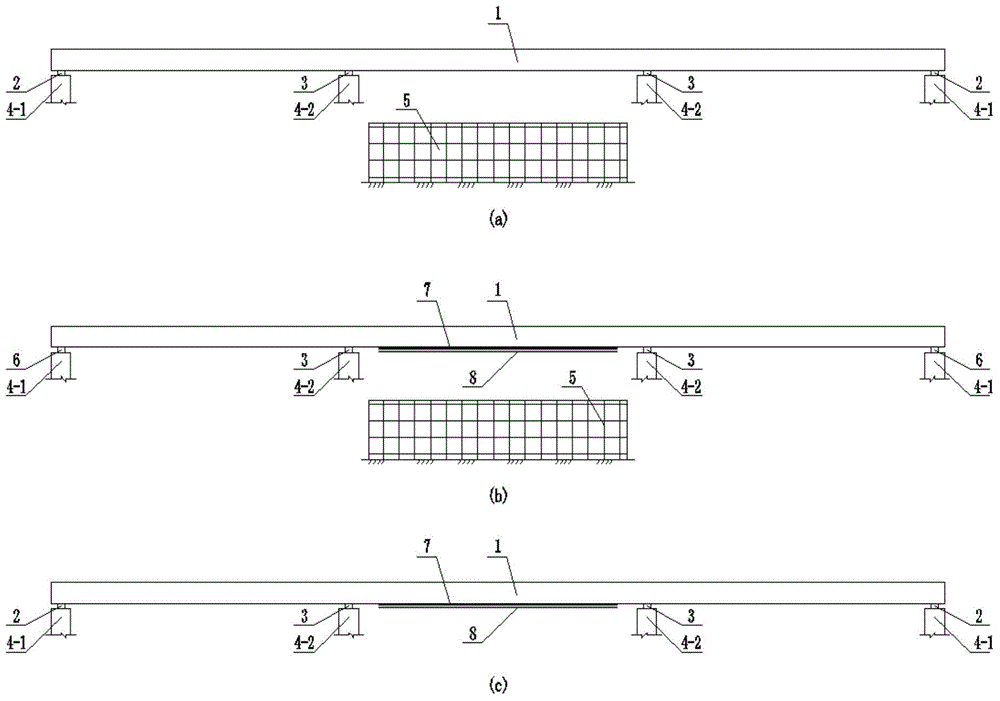

[0053] This embodiment is to strengthen the middle span of a certain three-span ordinary reinforced concrete continuous girder bridge, such as figure 1 As shown in the figure, the side-span support 2 is placed on the side-span pier 4-1, the mid-span support 3 is placed on the mid-span pier 4-2, and the main girder 1 is composed of the side-span support 2 and the mid-span support 3 Support, the span combination of the continuous girder bridge is (14+20+14)m, the main girder 1 is made of C40 concrete, the section is box-shaped, the section height is 1.4m, the roof width is 8.5m, the average thickness of the roof is 22.5cm, and the width of the bottom plate is 4.5m m; the height of the side-span support 2 and mid-span support 3 is 350mm, and the upper edge of the main beam at the mid-span support is equipped with 68 φ28HRB335 longitudinal tensile steel bars, and the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com