A desulfurization wastewater evaporation process and system

A desulfurization wastewater and evaporation system technology, applied in the field of desulfurization wastewater evaporation process and system, can solve the problems of high hardness of calcium and magnesium in desulfurization wastewater, difficulty in softening process control, high cost of softening chemicals, etc., to reduce total steam consumption and scaling risk Small, scale-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

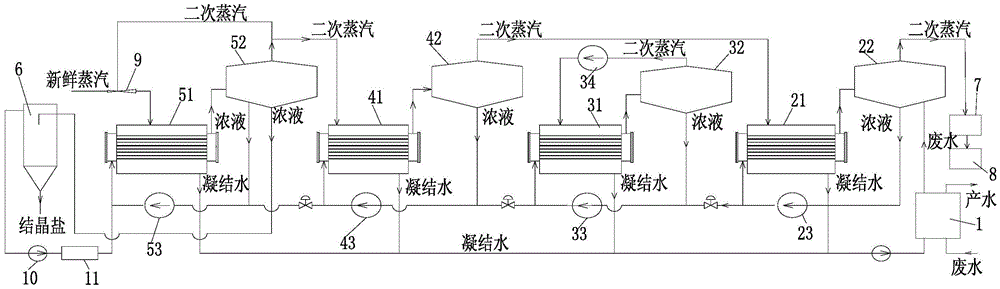

[0044] refer to figure 1 , the desulfurization wastewater evaporation system described in this embodiment includes a water-to-water heat exchanger 1, a primary heating evaporation device, a primary heating evaporation device, a secondary heating evaporation device, a tertiary heating evaporation device, a crystallization processor 6, and a cooler 7 and vacuum pump 8;

[0045] The primary heating evaporation device includes a primary heater 21, a primary flash tank 22 and a primary circulating pump 23 arranged between them;

[0046] The primary heating evaporation device comprises a primary heater 31, a primary flash tank 32 and a primary circulating pump 33 arranged between them; between the primary heater 31 and the primary flash tank 32, steam compressor 34;

[0047] The secondary heating evaporation device comprises a secondary heater 41, a secondary flash tank 42 and a secondary circulation pump 43 arranged between them;

[0048] The tertiary heating evaporation device ...

Embodiment 2

[0064] The characteristics of this embodiment are: the desulfurization wastewater evaporation system is the same as that of Embodiment 1, the difference is that the control parameters in the desulfurization wastewater evaporation process are different, as follows:

[0065] 1) Preheat the wastewater temperature to 80°C.

[0066] 2) Control the temperature of the primary flash tank at 98°C and the vacuum pressure at 0.094Mpa;

[0067] 3) Control the temperature of the primary flash tank at 100°C.

[0068] 4) Control the temperature of the secondary flash tank at 102°C.

[0069] 5) Control the temperature of the three-stage flash tank at 112°C.

[0070] 6) Control the temperature of the crystallization evaporator at 70°C.

[0071] Others are the same as in Example 1.

Embodiment 3

[0073] The characteristics of this embodiment are: the desulfurization wastewater evaporation system is the same as that of Embodiment 1, the difference is that the control parameters in the desulfurization wastewater evaporation process are different, as follows:

[0074] 1) Preheat the wastewater temperature to 85°C.

[0075] 2) Control the temperature of the primary flash tank at 100°C and the vacuum pressure at 0.1013Mpa;

[0076] 3) Control the temperature of the primary flash tank at 102°C.

[0077] 4) Control the temperature of the secondary flash tank at 104°C.

[0078] 5) Control the temperature of the three-stage flash tank at 114°C.

[0079] 6) Control the temperature of the crystallization evaporator at 75°C.

[0080] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com