Cultivating method for activated sludge for biochemically treating high-temperature salt-containing wastewater

A technology of activated sludge and biochemical treatment, which is applied in the fields of mining wastewater treatment, chemical instruments and methods, biological water/sewage treatment, etc., which can solve the problems of not mentioning the requirements of salinity, inapplicability of high temperature treatment, etc., and achieve salt tolerance High capacity, high efficiency of removing organic matter, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

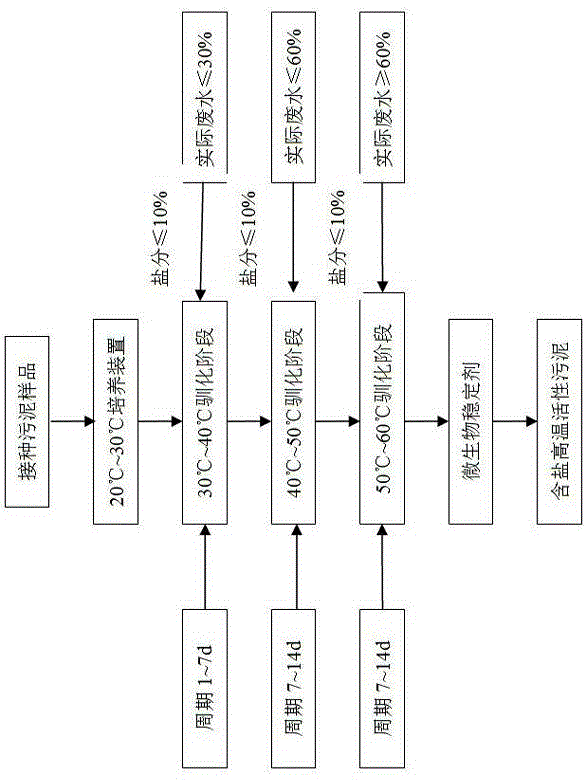

[0025] Embodiment 1, a kind of activated sludge cultivation method of saline high-temperature wastewater biochemical treatment, the method comprises the following steps:

[0026] (1) Take sludge samples and inoculate them in a culture device at 20°C, and conduct a batch acclimation culture to make the sludge concentration reach 500mg / L;

[0027] (2) Raise the temperature of the culture device to 30°C, carry out the second batch domestication culture, add the domestication nutrient solution and an appropriate amount of actual wastewater, so that the COD concentration of the influent is ≤2000mg / L, and maintain the mass fraction of salt in the wastewater as NaCl ≤10%, the domestication period is 1~7d, when the effluent COD removal rate is ≥90%, the cultivation is terminated, the flocculant is added for flocculation and sedimentation, the supernatant is discarded, and the next stage of cultivation is transferred;

[0028] (3) Raise the temperature of the culture device to 40°C, ca...

Embodiment 2

[0031] Embodiment 2, a kind of activated sludge cultivation method of saline high-temperature wastewater biochemical treatment, the method comprises the following steps:

[0032] (1) Take the sludge sample and inoculate it in a culture device at 30°C, and conduct a batch acclimation culture to make the sludge concentration reach 1500mg / L;

[0033] (2) Raise the temperature of the culture device to 40°C, carry out the second batch domestication culture, add the domestication nutrient solution and an appropriate amount of actual wastewater, so that the COD mass concentration of the influent is ≤2000mg / L, and maintain the mass fraction of salt in the wastewater as NaCl ≤10%, the domestication period is 1~7d, when the effluent COD removal rate is ≥90%, the cultivation is terminated, the flocculant is added for flocculation and sedimentation, the supernatant is discarded, and the next stage of cultivation is transferred;

[0034] (3) Raise the temperature of the culture device to 5...

Embodiment 3

[0037] Embodiment 3, a kind of activated sludge cultivation method of saline high-temperature wastewater biochemical treatment, the method comprises the following steps:

[0038] (1) Take the sludge sample and inoculate it in a culture device at 25°C, and conduct a batch acclimation culture to make the sludge concentration reach 1000mg / L;

[0039] (2) Raise the temperature of the culture device to 35°C, carry out the second batch domestication culture, add the domestication nutrient solution and an appropriate amount of actual wastewater, so that the COD mass concentration of the influent is ≤2000mg / L, and maintain the mass fraction of salt in the wastewater as NaCl ≤10%, the domestication period is 1~7d, when the effluent COD removal rate is ≥90%, the cultivation is terminated, the flocculant is added for flocculation and sedimentation, the supernatant is discarded, and the next stage of cultivation is transferred;

[0040] (3) Raise the temperature of the culture device to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com