Shock-resistant energy-absorbing material and preparation method thereof

An energy-absorbing material and impact-resistant technology, which is applied in the field of impact-resistant energy-absorbing materials and their preparation, can solve problems such as the inability to use structural materials, rough surfaces, and low strength of foam materials, and achieve improved impact-resistant energy-absorbing performance, high viscosity The effect of improving bonding strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing an impact-resistant energy-absorbing plate, the specific steps are as follows:

[0027] 1. Prepare the metal panel and metal foam layer according to the design size requirements;

[0028] 2. The bonding surfaces of the metal panel and the metal foam layer are respectively coated with a special heat vulcanizing adhesive for rubber;

[0029] 3. Prepare the rubber compound according to the design thickness requirements, and cut it according to the size of the metal panel and the metal foam layer;

[0030] 4. Preheat the die-casting mold to the temperature range that can vulcanize the rubber;

[0031] 5. Place the metal panel, rubber and foam metal plate in the mold in sequence according to the design structure;

[0032] 6. Clamp the mold and apply pressure to keep the pressure, so that the rubber can be vulcanized and molded under the designed temperature, pressure and time conditions;

[0033] 7. Take out the product after ejecting the mold to co...

Embodiment 1

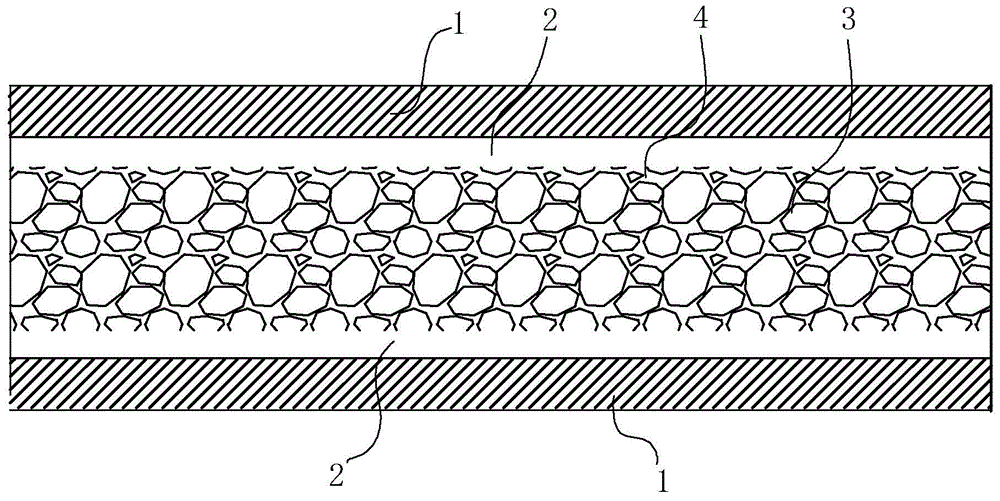

[0035] Example 1 (through-hole foam metal sandwich panel)

[0036] The structure of the through-hole foam metal sandwich panel is as follows: figure 1 As shown, the characteristics of this structure are: the metal panel 1 has two layers, the metal panel 1 is used as the outermost layer of protection to resist the direct attack of foreign objects, and at the same time effectively restrains the internal protection materials of each layer; the foam metal layer 3 adopts a common Porous aluminum foam, nickel foam or copper foam, metal foam layer 3 as the main internal energy-absorbing protection material consumes impact energy through its own irreversible plastic deformation; metal panel 1 and foam layer 3 are connected by vulcanization through rubber layer 2 , the rubber layer 2 has the characteristics of isolating vibration and absorbing shock. In addition, the amount of rubber added can be controlled quantitatively. Under the condition of a certain thickness of the plate, the ad...

Embodiment 2

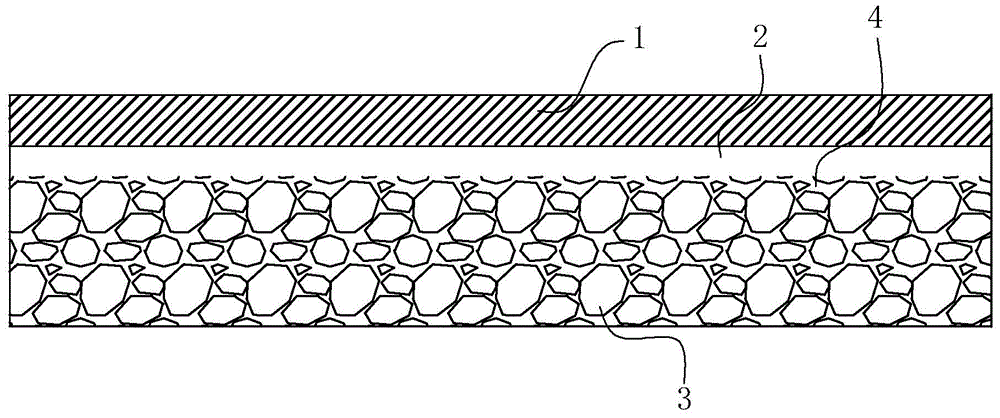

[0037] Embodiment 2 (through-hole foam metal composite board)

[0038] The through-hole foam metal composite panel is an extension of the through-hole foam sandwich panel. It is necessary to explain it separately here. Its structure is as follows figure 2 shown. The characteristics of this structure are: the metal panel 1 is one layer, which is used as the outermost layer of protection to resist the direct attack of foreign objects, and at the same time effectively restrains the internal protection materials of each layer; the foam metal layer 3 adopts foamed aluminum with through holes, foam Nickel or copper foam, the metal foam layer 3 as the innermost layer of protection consumes impact energy through its own irreversible plastic deformation; the metal panel 1 and the metal foam layer 3 are vulcanized and connected through the rubber layer 2, and the rubber layer 2 has the functions of isolating vibration, absorbing Impact and other characteristics, in addition, the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com