Shear thickening fluid/carbon nanotube foam shock-resistant energy-absorbing material, preparation method and application

A carbon nanotube and energy-absorbing material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the settlement and leakage of shear thickening liquid, increase the weight of impact-resistant protective materials, and increase impact-resistant energy-absorbing materials and other problems, to achieve the effect of improving the impact resistance energy absorption performance and energy dissipation ability, overcoming the incompatibility of flexibility and impact resistance, and improving the impact resistance energy absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

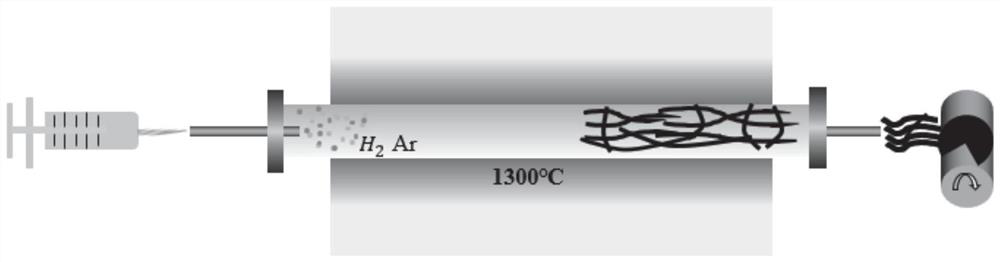

Method used

Image

Examples

preparation example Construction

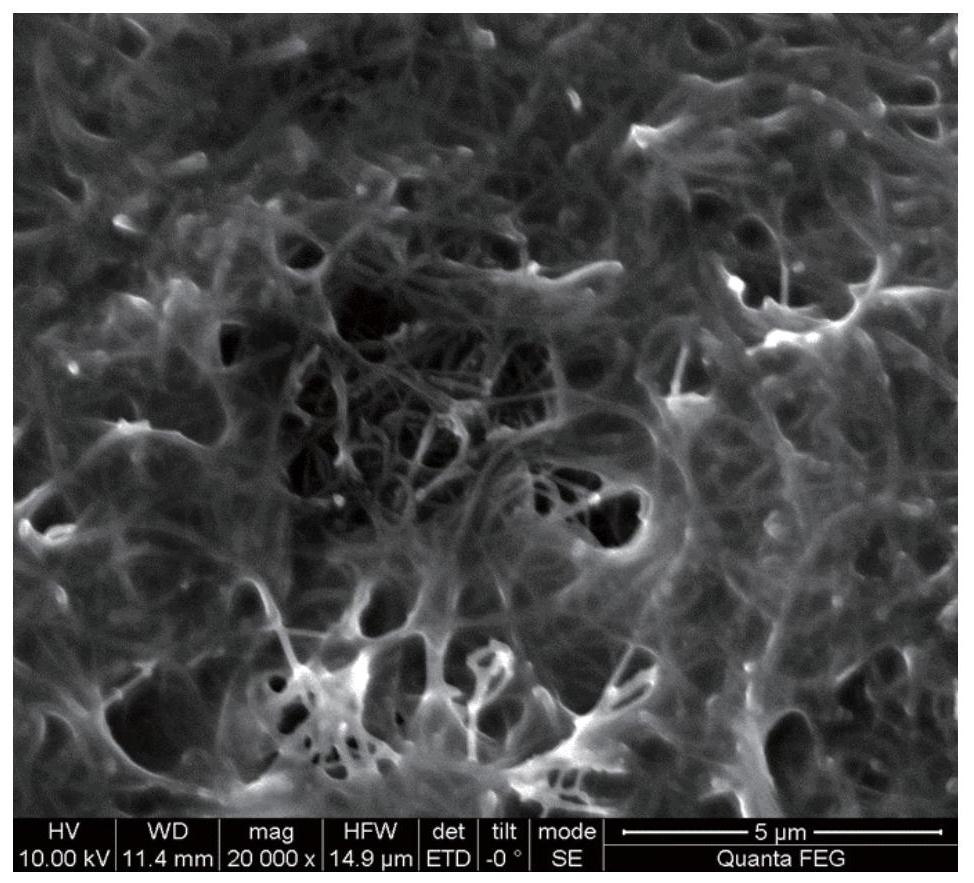

[0037] Further, the time of the dipping treatment is 2~12h, preferably 6h.

[0039] Further, the carrier gas includes an inert gas, and is not limited thereto.

[0040] Further, the inert gas includes argon, and is not limited thereto.

[0041] Further, the rate at which the carrier gas is introduced into the reaction chamber is 1200 sccm.

[0043] Further, the rate at which the carbon source is introduced into the reaction chamber is 50sccm.

[0044] Further, the reducing gas includes hydrogen, and is not limited thereto.

[0045] Further, the rate at which the reducing gas is introduced into the reaction chamber is 90 sccm.

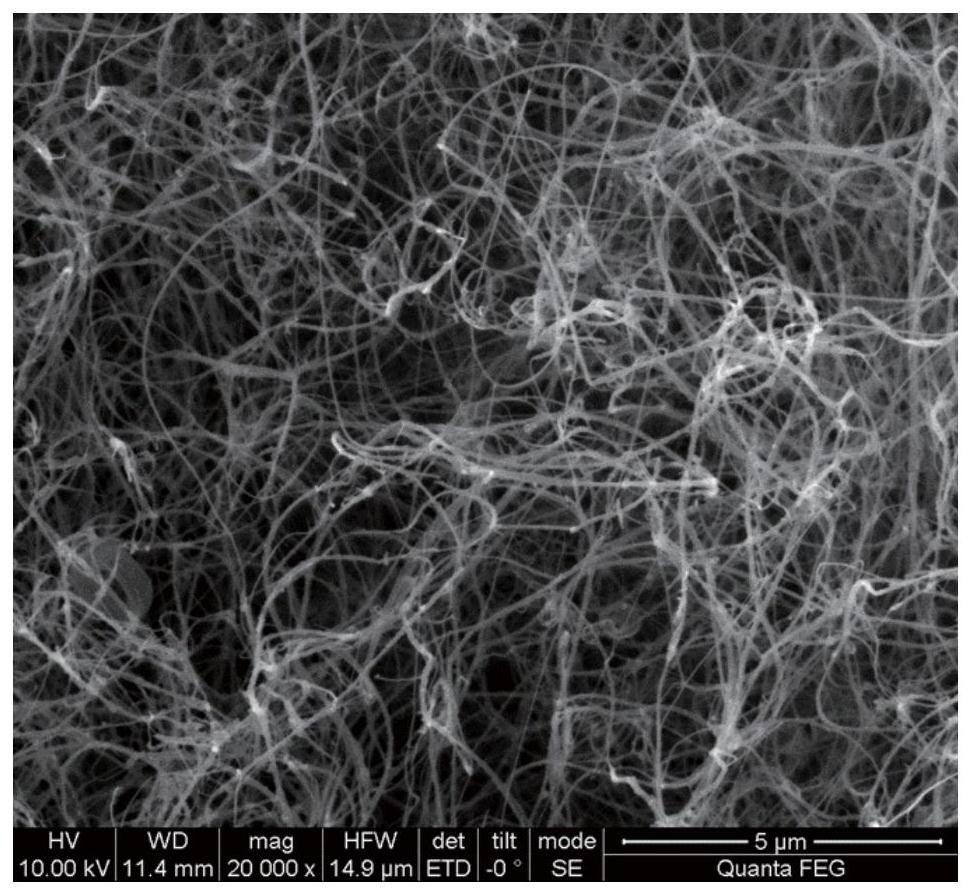

[0049] Further, the pore diameter of the contained pores is 100 nm to 50 μm.

Embodiment 1

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com