Guide and guard guide roller openness adjusting device

A technology for adjusting device and opening degree, which is applied in the field of steel rolling, can solve problems such as wear and tear at the end of the guide roller, and damage to the cooperation between the guide roller and the worm wheel, and achieve the goal of maintaining the opening degree of the guide roller, relieving stress concentration, and ensuring surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

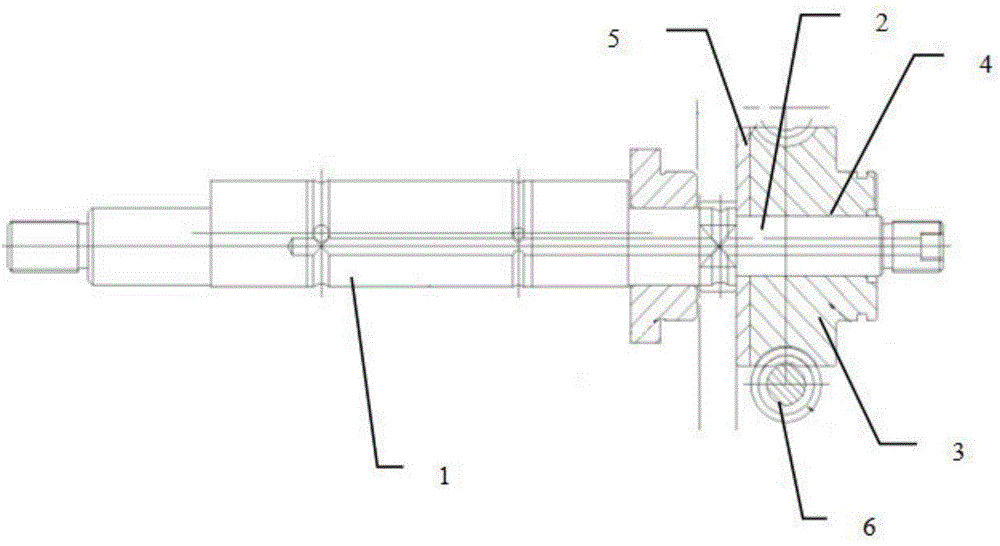

[0023] Such as figure 1 As shown, a device for adjusting the opening degree of guide rollers, including:

[0024] A guide roller, which includes a guide roller body and a guide roller shaft 1, the guide roller body is sleeved on the outside of the guide roller shaft 1 and is driven by the guide roller shaft 1 to move in a circumferential direction, wherein the guide roller shaft 1 It is an eccentric shaft, and the end of the guide roller shaft 1 is provided with a connecting shaft 2;

[0025] The worm wheel 3 is movably connected with the connecting shaft 2 at the end of the guide roller shaft 1, and the movably connecting mode is: the worm wheel 3 is provided with a groove 4 matching the connecting shaft 2, and the connecting The shaft 2 is embedded in the groove 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com