Cassiterite flotation agent composition

A flotation agent and composition technology, applied in flotation, solid separation, etc., can solve the problems of increased dosage, high cost, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

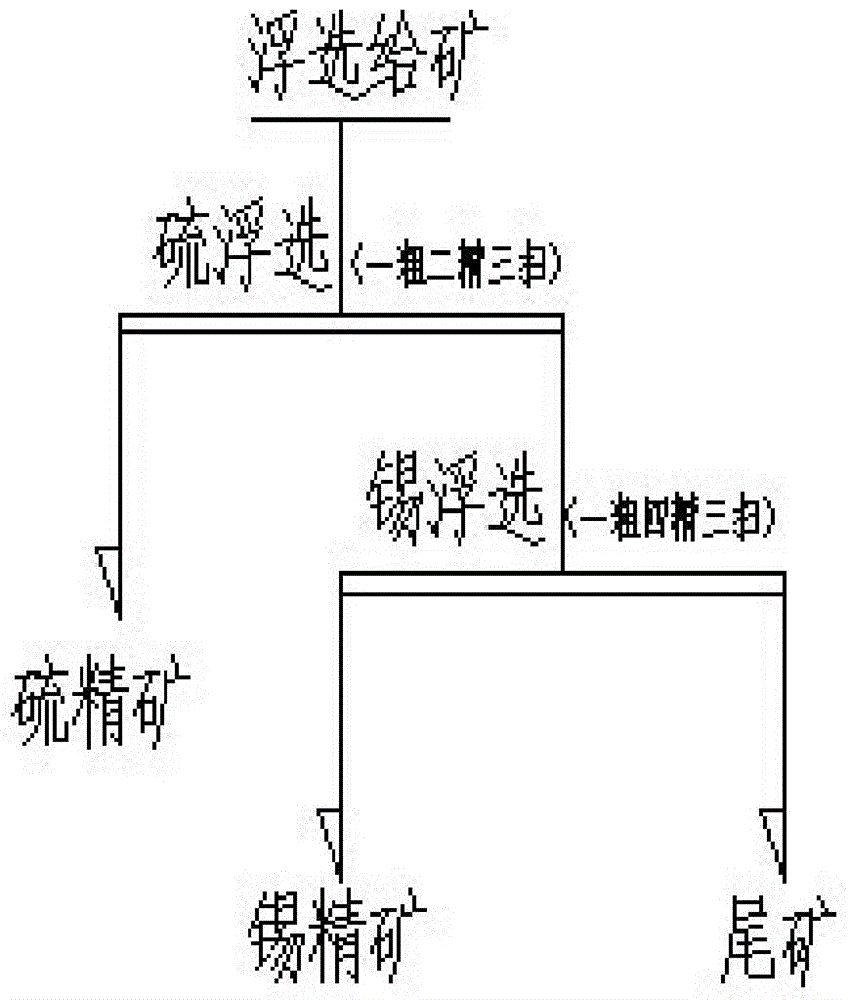

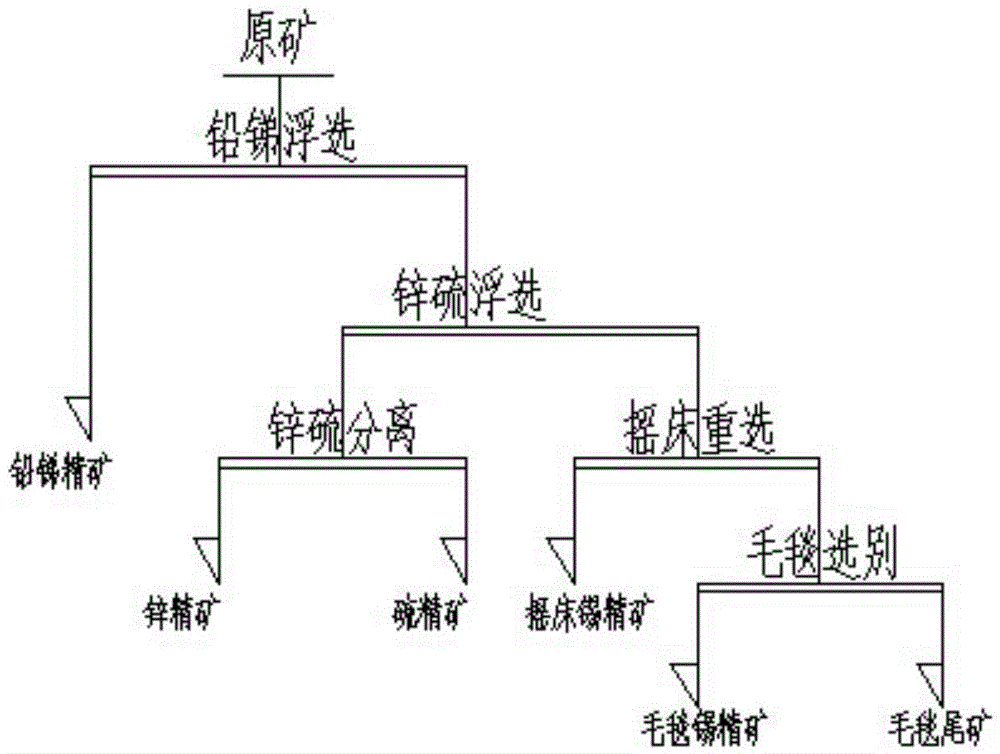

Method used

Image

Examples

example 1

[0088] (1) Analyze the tin phase of the gravity separation tailings of the ore dressing plant in Linwu County South Mining Co., Ltd., Linwu County, Hunan Province. The analysis results are shown in Table 2.

[0089] Table 2, Gravity separation tailings tin phase analysis

[0090]

[0091]

[0092] The phase analysis shows that the tin grade of gravity separation tailings is 0.72%, among which the tin minerals are mainly cassiterite, the tin content in cassiterite occupies 79.17%, the tin content in phryotinite occupies 13.89%, and the colloidal tin ore The tin content in it accounts for 6.94%. Owing to the existence of zurtzite and colloidal tin, and the total amount accounts for 20.83%, it will have an adverse effect on the recovery rate of tin flotation.

[0093] (2) Particle size analysis of tin

[0094] After sampling and chemical analysis of the gravity separation tailings, the gravity separation tailings contain 0.33% lead, 0.15% zinc and 0.68% tin. The analysis...

Embodiment 1

[0098] Embodiment 1: the preparation of pharmaceutical composition of the present invention

[0099] Mix collectors, co-collectors and inhibitors as listed in Table 4:

[0100] The dosage and the mode of use of the pharmaceutical composition in table 4, embodiment 1

[0101]

[0102] Among them, WP is salicylhydroxamic acid provided by Guangzhou Institute of Nonferrous Metals.

[0103] The flotation process steps of pre-sizing and grading are the same as those of gravity tailings flotation process steps.

Embodiment 2

[0105] The collector, auxiliary collector and inhibitor were mixed in the manner listed in Table 5, and a comparative test was carried out with the agent in Example 1 when re-selecting floating tin from tailings. (i.e. process excluding pre-sizing and classifying compared to process including pre-sizing and classifying)

[0106] Medicament type, consumption and method of use in table 5, embodiment 2

[0107]

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com