A paint color matching system with dynamic data distribution function

A technology for assigning functions and dynamic data, applied in the field of paint toning systems, which can solve the problems of obvious color difference and inaccurate measurement of final paint products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

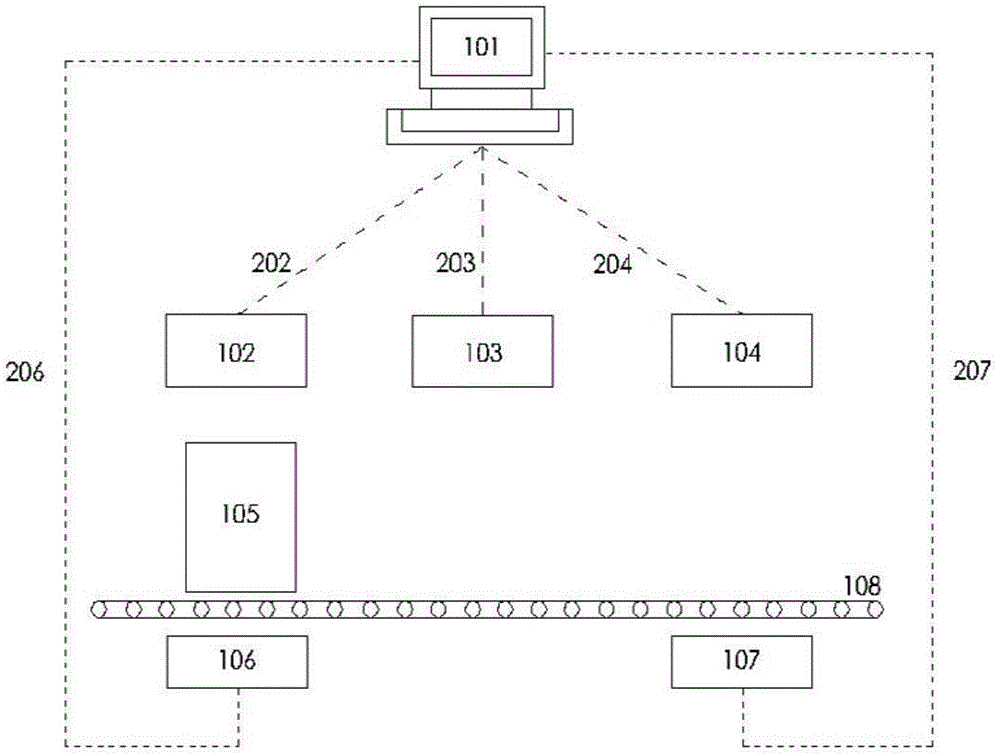

[0016] figure 1 Represents a paint tinting system 100 with dynamic data distribution, including:

[0017] 101- Color matching control subsystem (including programmable controller PLC control system and man-machine interface);

[0018] 102-weight metering color paste distributor;

[0019] 103-Volume metering color paste distributor;

[0020] 104 - gravimetric base paint dispenser;

[0021] 105-color bucket;

[0022] 106 - Weight metering color paste weighing scale;

[0023] 107-Weighing weighing scale for basic paint;

[0024] 108-Toning barrel transmission line;

[0025] 202-The signal transmission data line of the weight metering color paste distributor;

[0026] 203-Volume metering color paste distributor signal transmission data line;

[0027] 204 - Signal transmission data cable for weight metering base paint dispenser;

[0028] 206- Weight metering color paste weighing scale signal feedback data line;

[0029] 207-The signal feedback data line of the weight meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com