Piston-cylinder arrangement, in particular a slave cylinder for a hydraulic clutch actuating device

An operating device, piston cylinder technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of slave cylinder damage, indirect damage, etc., and achieve the effect of reducing cost and manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

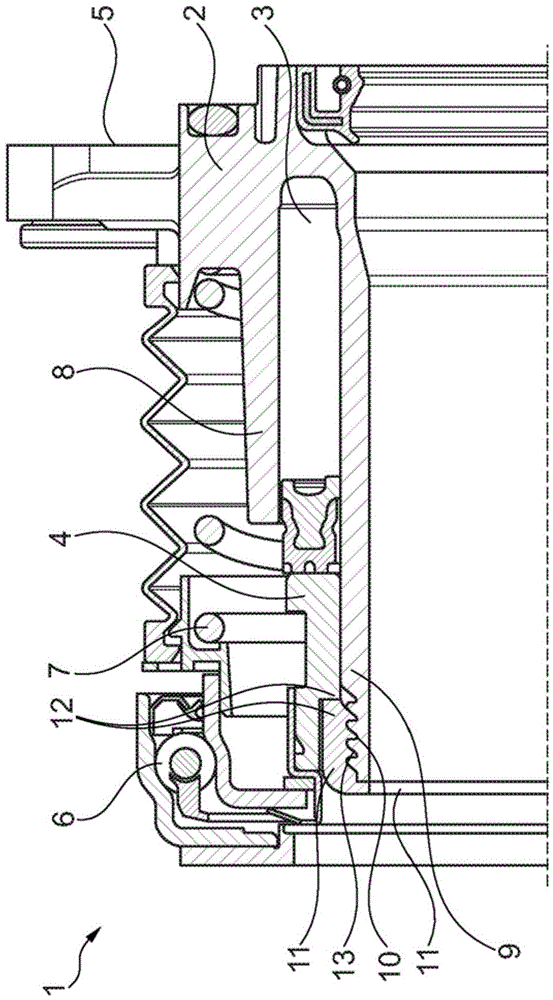

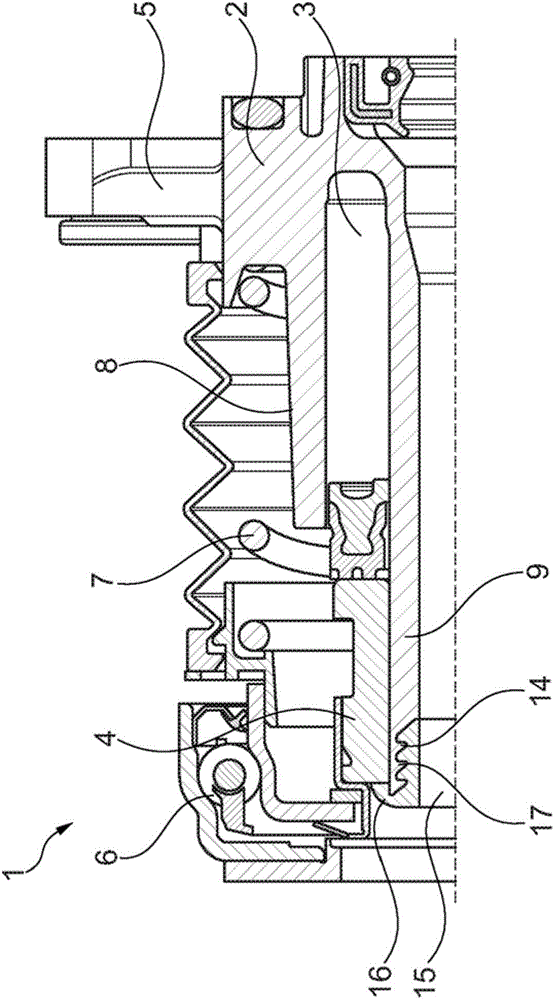

[0020] exist figure 1 A first exemplary embodiment of a slave cylinder 1 is shown in , which is inserted into a dual clutch transmission. The slave cylinder 1 here consists of a cylinder housing 2 made of plastic, which has an annular pressure chamber 3 in which a piston 4 is mounted so that it can move in the axial direction. Via a connecting line, not further shown, of the cylinder housing 2 , hydraulic fluid enters the pressure chamber 3 and actuates the piston 4 and thus the release bearing 6 .

[0021] The preload spring 7 , which is prestressed against the release bearing 6 , is pressed against the cylinder housing 2 in the region of the fastening device 5 of the slave cylinder. To form the pressure chamber 3 , the cylinder housing 2 has an outer wall part 8 and an inner wall part referred to as a guide sleeve 9 . An external thread 10 is formed on the guide sleeve 9 , onto which a stop nut 11 is screwed. The stop nut 11 engages in the recess 12 of the piston 4 when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com