A rectifier cabinet for a power generation vehicle

A technology for rectifier cabinets and power generation vehicles, which is applied in the modification of electrical components and power electronics, and the conversion of AC power input into DC power output, etc. To achieve the cooling effect and other problems, to achieve the effect of increasing the natural cooling effect, easy operation, easy ventilation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

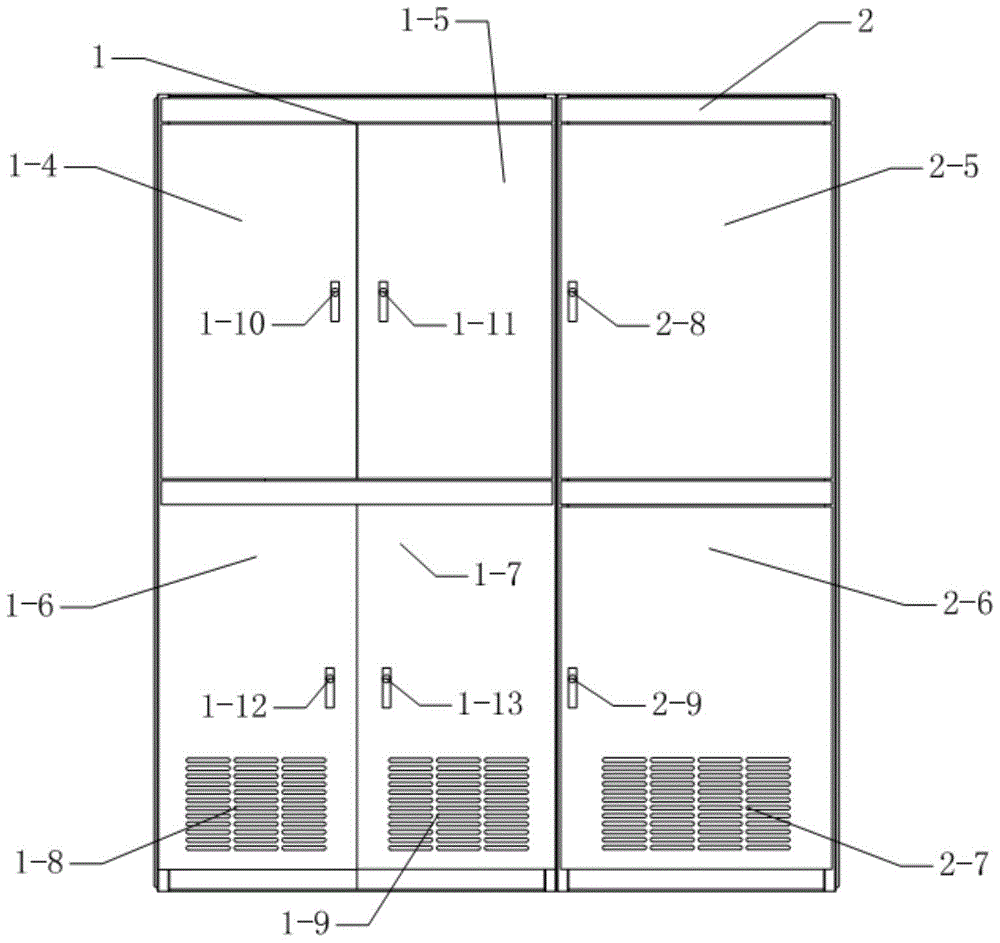

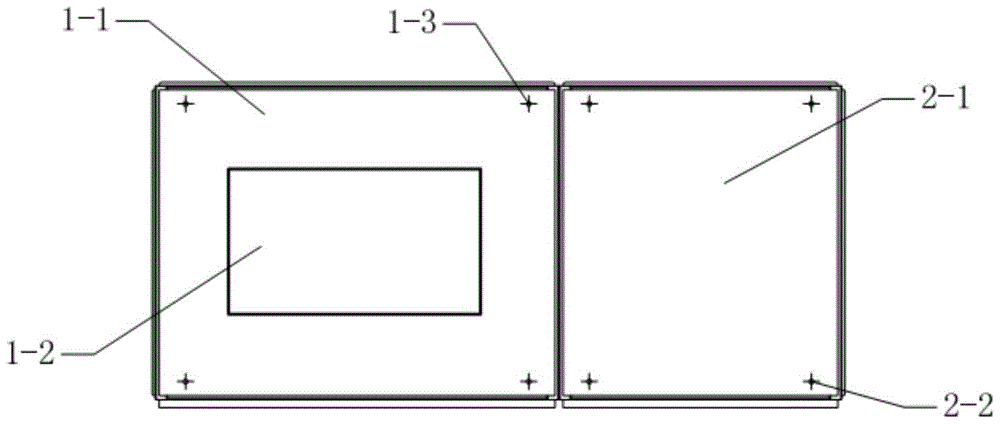

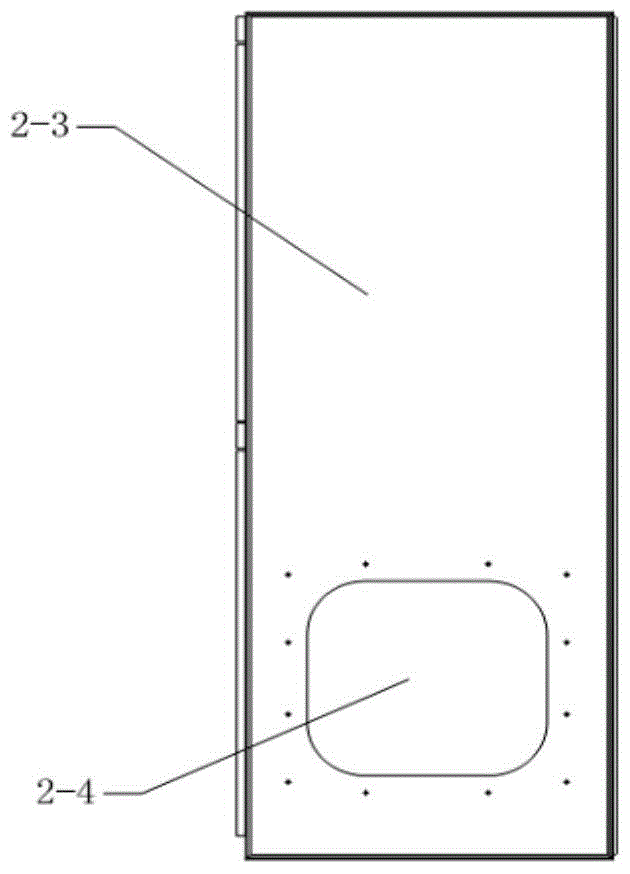

[0030] Such as Figure 1 ~ Figure 4As shown, a rectifier cabinet for a power generation vehicle of the present invention includes a rectifier box 1 and a control box 2, the rectifier box 1 and the control box 2 are arranged side by side, and the rectifier box 1 and the control box 2 are connected by hexagon bolt The two cabinets are fixed into one cabinet, and there is no sealing plate between the two cabinets.

[0031] The rectifier box 1 includes a rectifier box upper sealing plate 1-1, an upper vent 1-2, a rectifier box lifting ring screw 1-3, a rectifier box upper left door panel 1-4, a rectifier box right upper door panel 1-5, a rectifier box left lower door panel 1-6, right lower door panel of rectifier box 1-7, shutter of left lower door panel of rectifier box 1-8, shutter of right lower door panel of rectifier box 1-9, left upper door handle and door lock assembly of rectifier box 1-10, right upper door handle of rectifier box And door lock assembly 1-11, rectifier bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com