Prebaked anode aluminum electrolytic bath

A technology of aluminum electrolytic cells and prebaked anodes, which is applied in the field of aluminum electrolytic cells, can solve the problems of excessive cover plate gap, high temperature of the tank shell, and affecting the life of the tank, and achieve high anode current density, reduce loss along the process, and enhance The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

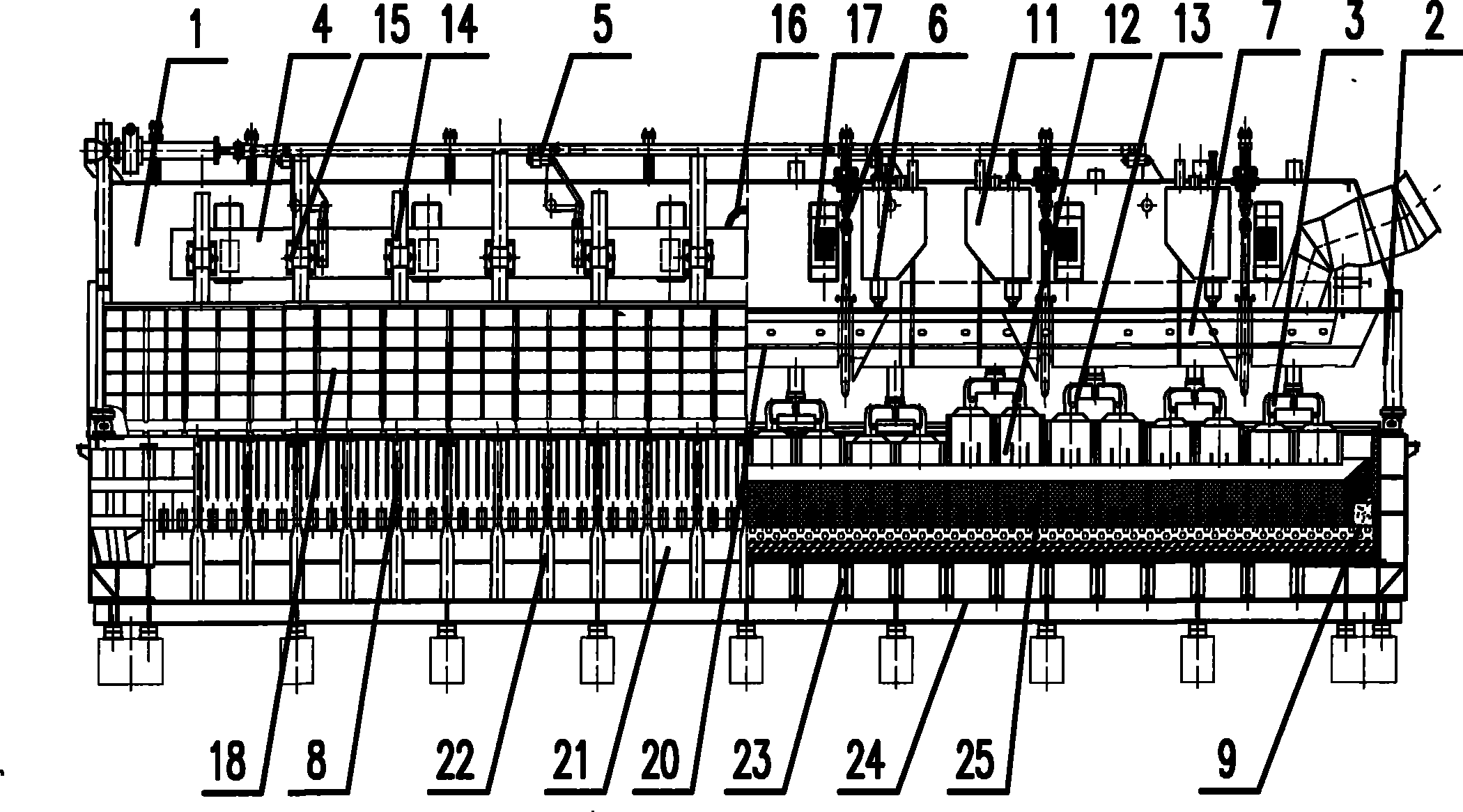

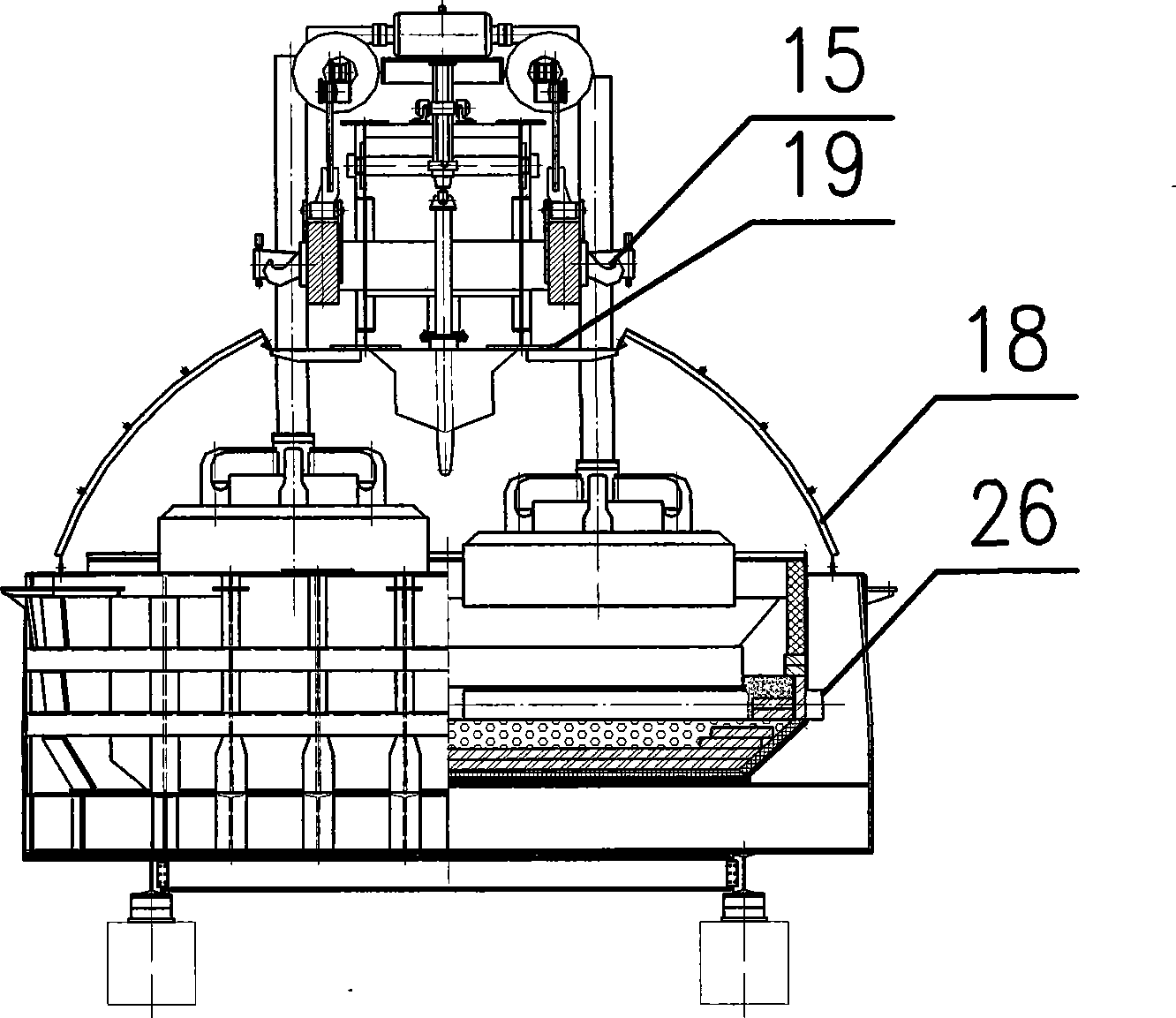

[0047] The structure of the inventive prebaked anode aluminum electrolytic cell above 400kA level will be described in detail below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited by the embodiments.

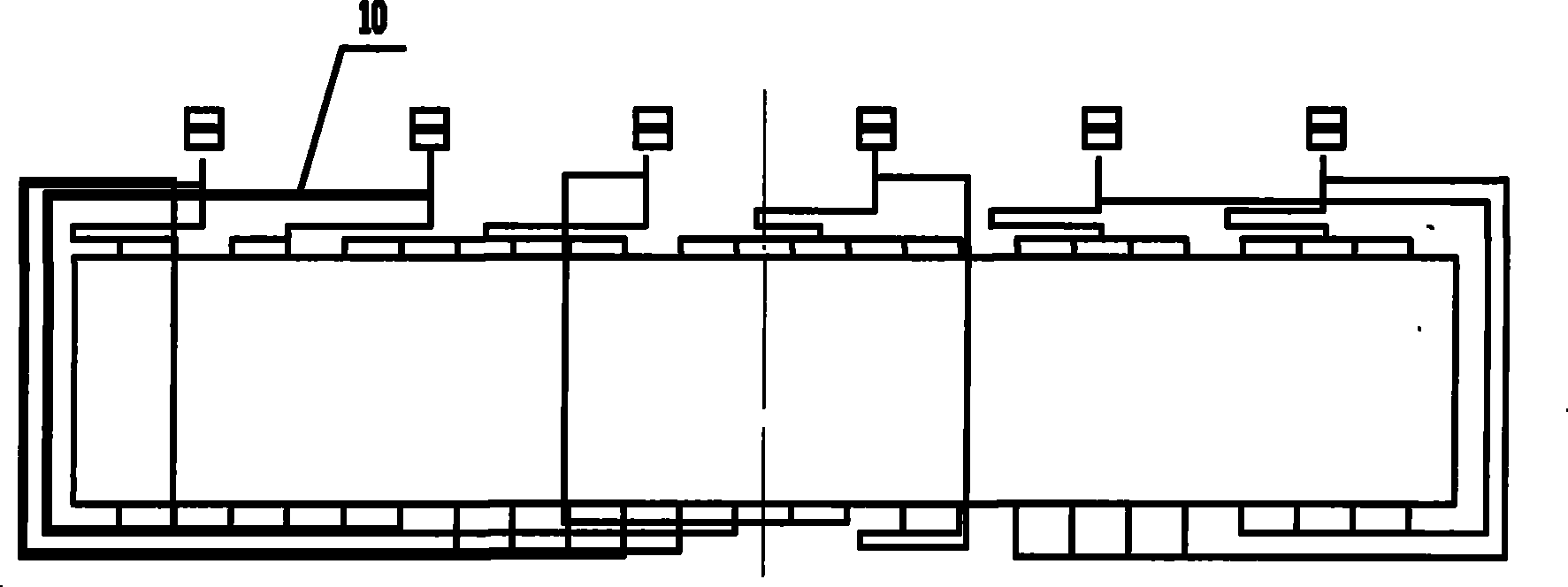

[0048] The aluminum electrolytic cell structure of the present invention is suitable for prebaked anode aluminum electrolytic cells above 400kA level. Its structure is as follows: the electrolytic cell of the present invention is mainly composed of three major parts, the upper structure, the cathode structure and the cathode bus bar. The upper structure is mainly composed of girder 1, door-shaped column 2, anode carbon block group 3, anode busbar 4, anode lifting mechanism 5, shelling and feeding system 6, and airtight smoke exhaust system 7; the cathode structure is mainly composed of welding, heat dissipation Type cradle tank shell 8 and lining 9; cathode busbar 10 adopts asymmetrical design.

[0049] The gird...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com