Process method for conformally assembling sip devices on curved surface pcb substrate

A technology of arc-shaped curved surface and process method, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problem that it is difficult to meet the requirements of SIP packaging and assembly, the heat dissipation capacity of spherical interconnect pins is insufficient, and the top of the device cannot be added. To solve the problems of installing heat dissipation liner, etc., to shorten the development cycle, optimize the shear stress and vibration stress release effect, and achieve good assembly reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

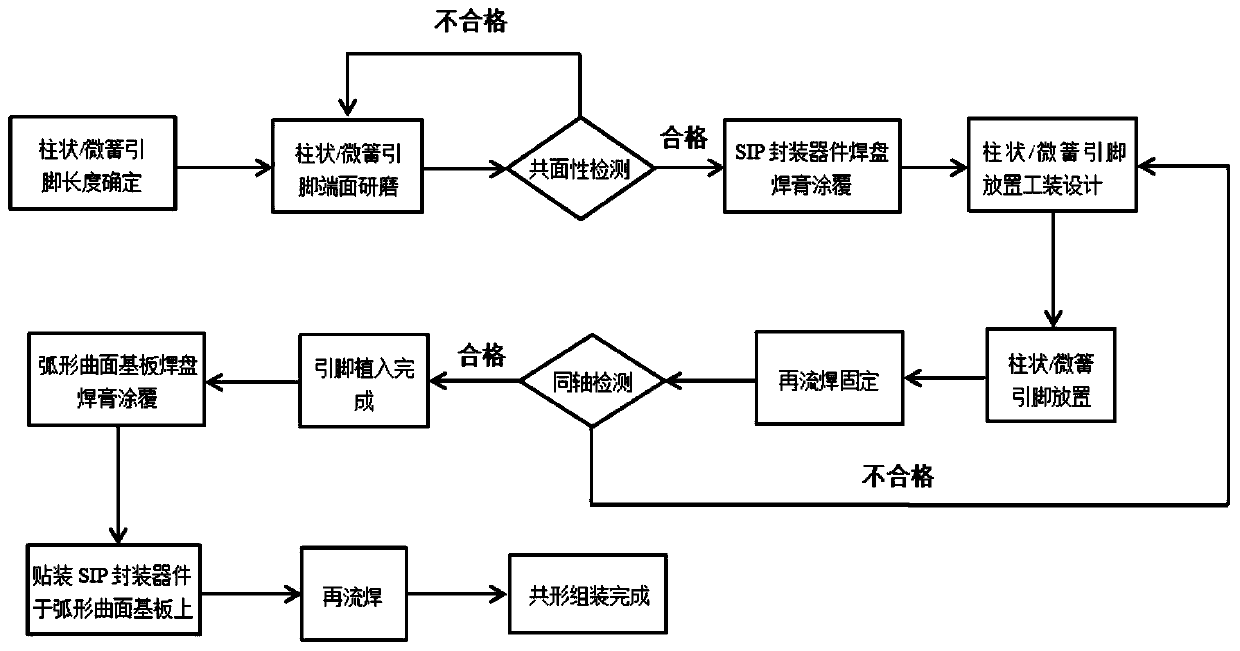

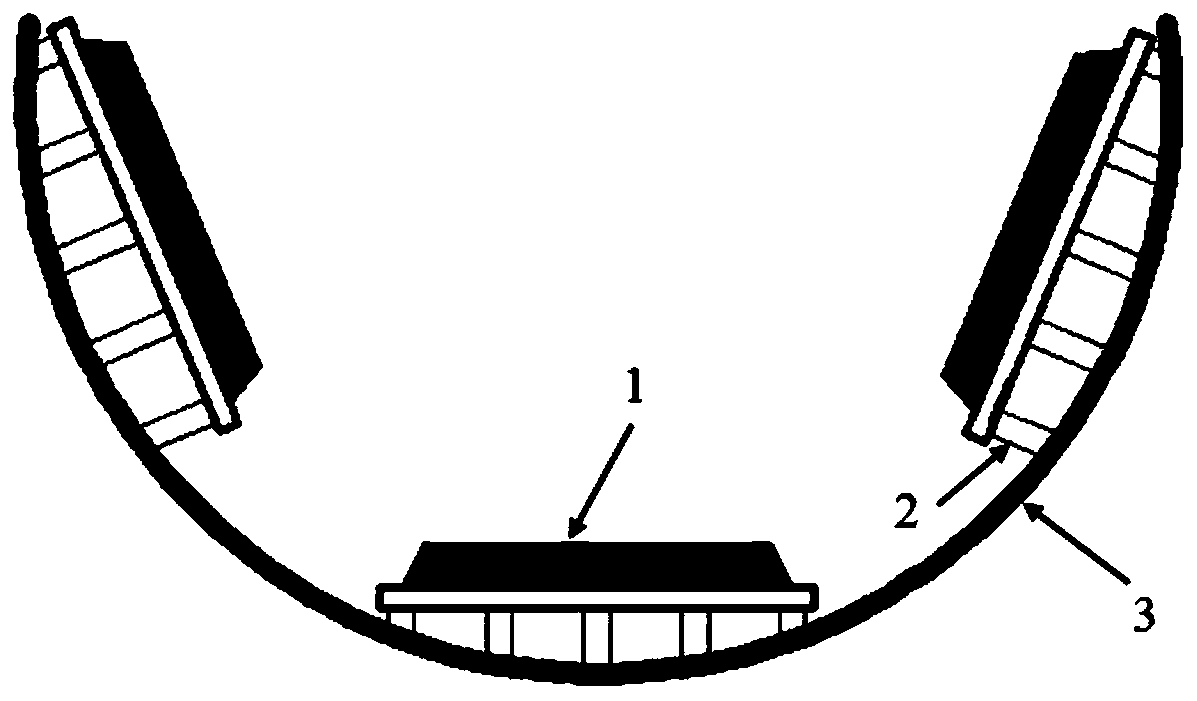

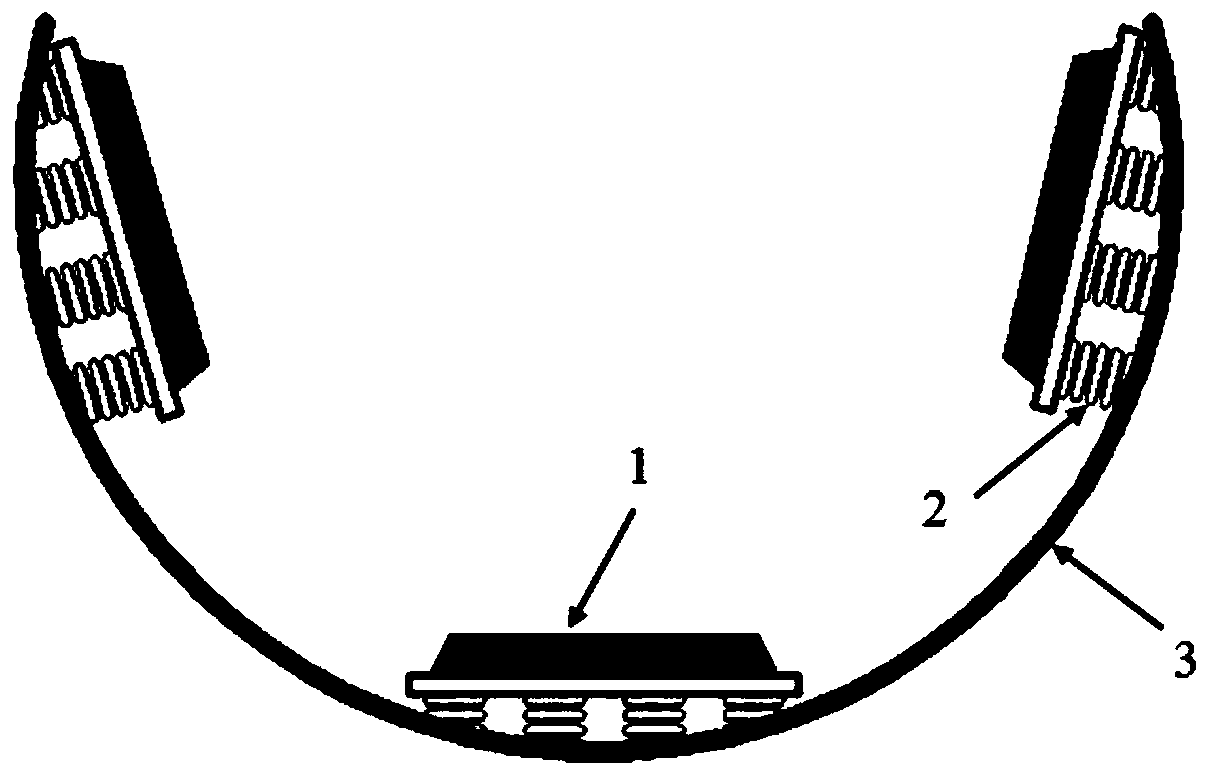

[0018] refer to figure 1 According to the present invention, two new types of interconnection pins (column, microspring form) provided will be implanted into SIP devices and assembled with substrates to realize the technological process of conformal assembly of SIP devices 1 on arc-shaped curved surface PCB substrates 3. The specific implementation method is as follows: : According to the shape and size parameters of the arc-shaped surface of the PCB substrate, determine the length of each columnar or microspring pin that matches it, so as to make columnar or microspring pins 2 with the same or different lengths; for columnar or microspring pins Pin 2 is ground to ensure the coplanar consistency between the end face of the pin and the assembly surface of the substrate, and passes the coplanarity test; solder paste is applied to the pad of the SIP device; it is specially designed for columnar or micro-spring pin 2 The pin placement tooling; place the columnar or micro-spring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com