Method for adaptively and dynamically scheduling manufacturing systems

A technology for dynamic scheduling and manufacturing systems, applied in control/regulation systems, non-electric variable control, speed/acceleration control, etc., can solve the problem of ignoring the dynamic accumulation of learning experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

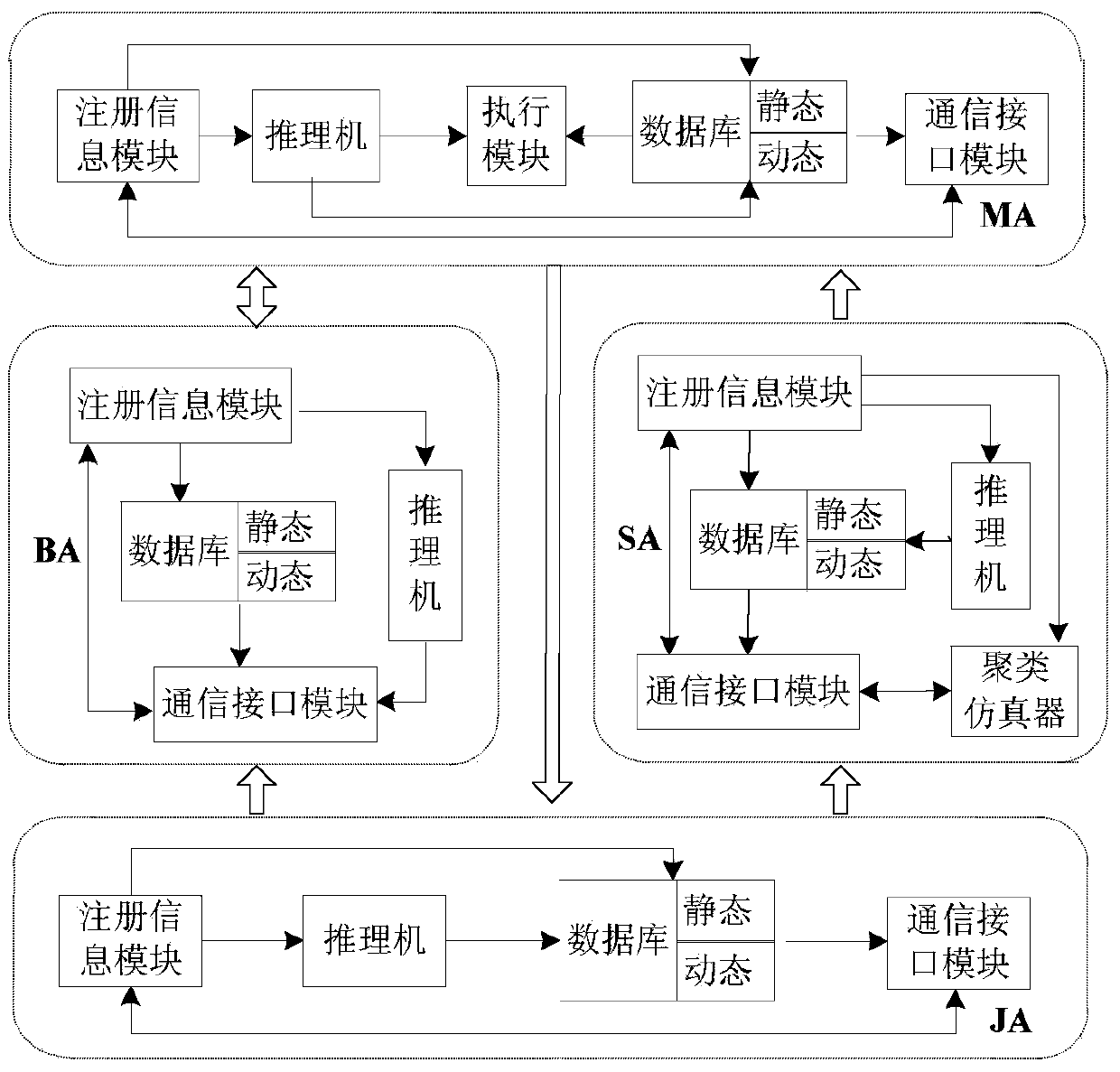

[0045] The invention discloses a method for adaptive dynamic scheduling of a manufacturing system, which includes the following content:

[0046] 1. Design the dynamic scheduling objective function. The definition of symbols in the scheduling process is given as follows: the job shop set is expressed as J={J 1 ,J 2 ,…J N}; The set of processing equipment is M={M 1 , M 2 ,...M M}; Each job consists of multiple processes, O ij Indicates job J i The processing time of the j-th process of the same operation cannot be processed on the same equipment, and one equipment can only process one process in a certain period of time; the operations are independent of each other and have no priority, and the operation J i The actual completion time is C i , the arrival time is AT i , lead time D i The formula is as follows:

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com