Emission reduction and energy saving system capable of omitting GGH

An energy-saving system and the technology of this system, which are applied in the field of emission reduction and energy-saving systems, can solve the problems of "gypsum rain, corrosion and blockage, and high resistance that are prone to occur in chimneys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

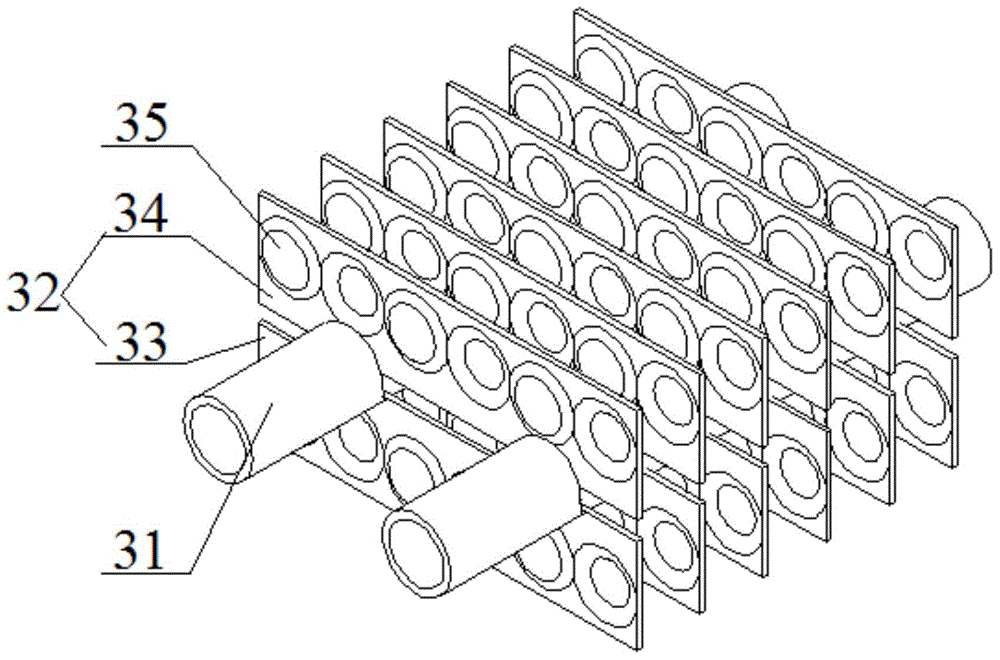

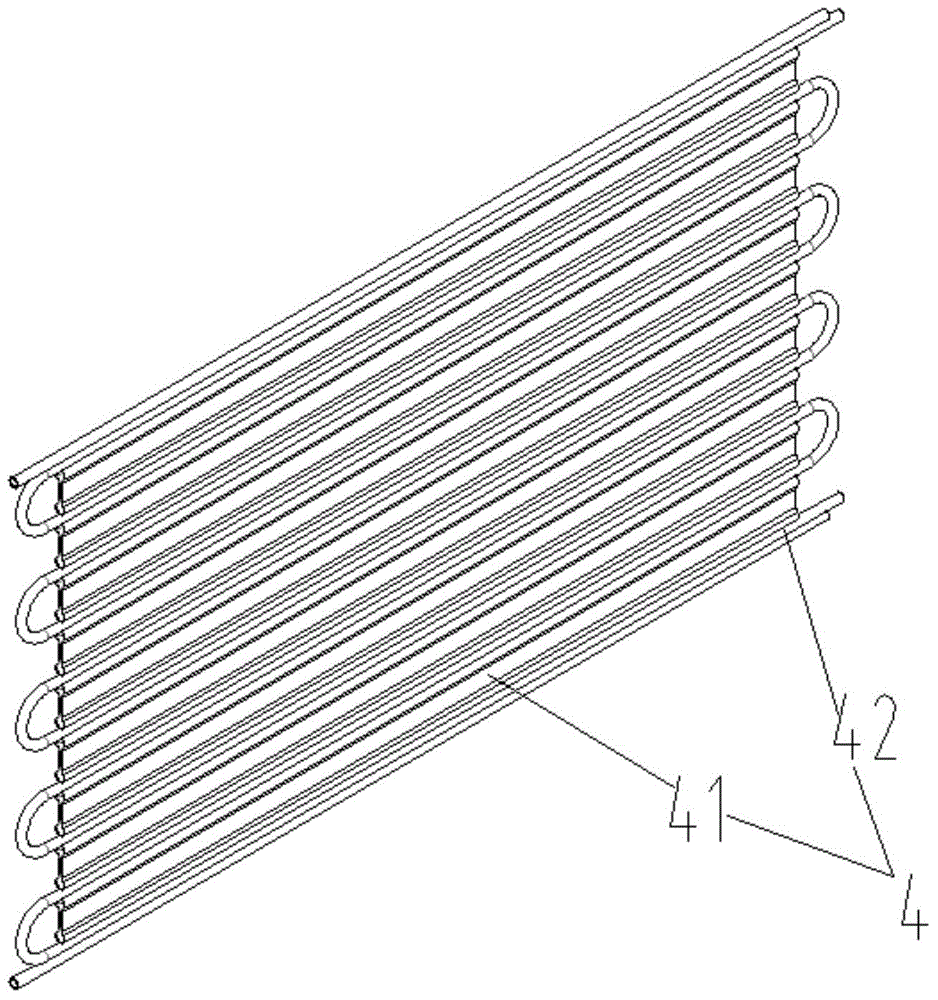

[0027] Such as figure 1 As shown, the present invention discloses an emission reduction and energy saving system capable of canceling GGH, comprising an air preheater 1, a high-temperature heat exchanger 2, a first stage 3 of a low-temperature heat exchanger, and a dry-type Electrostatic precipitator 13, induced draft fan 14, booster fan 15, second section 4 of low temperature heat exchanger, desulfurization tower 16, wet electrostatic precipitator 17, third section 32 of low temperature heat exchanger and chimney 18; The air heat exchanger 42 of the cold secondary air channel 12 and the secondary fan 19, the output end of the secondary fan 19 is connected to the air side input end of the air preheater 1 through the air heat exchanger 42; the system It also includes a low pressure heater 5, a first water pump 7, a second water pump 8 and a third water pump 9;

[0028] The low-pressure heater 5 is connected in series to the main condensate pipeline of the steam turbine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com